Retrofit Considerations When Switching To LEDs for Explosion Proof Lighting

Published 12 Jul 2019

-

uploaded by Chris Dodds - Sales & Marketing Manager Thorne & Derrick

Lighting for hazardous areas

Frustrated by frequent maintenance, poorly lit areas, and high-energy consumption, you’ve decided to upgrade your facility’s explosion proof lighting. You’ve gotten your manager’s approval for the retrofit of the lighting and are eager to begin the switch to LEDs.

💡 Did you Know? Thorne & Derrick using latest software provide a FREE LIGHTING DESIGN SERVICE for the specification and supply of ATEX & IECEx Certified light fittings to provide safe and reliable lighting in explosive atmospheres and hazardous area locations.

But, before you purchase your lighting fitting and fixtures and start the installation, consider these 10 factors.

factors to consider

1. Request sample light fittings or fixtures: Have you evaluated a sample lighting fixture? Always request a sample prior to settling on a fixture design. Nothing compares to seeing a fixture hung in the actual application, and most manufacturers have a sample program to “try out” a lighting fixture prior to making a large investment. Enhancements in colour rendering, and a variety of choices in colour temperatures, optics, and brightness levels allow you to truly customize your hazardous area lighting design to meet the needs of your specific application.

2. Research rebates and incentives: Are there rebates available in your area? Do the hazardous area lighting fixtures you’re considering appear on the Designlights™ Consortium’s Qualified Products List (DLC QPL)? Most agencies require a hazardous area luminaire to appear on this list in order to be considered eligible for state and utility energy efficiency program incentives. The Database of State Incentives for Renewables & Efficiency (DSIRE®) is another great resource tool for finding incentives in the United States.

Explosion Proof Lighting | Switching to LED

3. Consider fixture reliability and luminaire lifespan: How long do you plan on keeping your lighting fixtures? How often are you willing to perform hazardous area maintenance tasks, such as driver replacement? For many, the ultimate objective is to upgrade their lighting — reducing maintenance and manpower requirements while maintaining or increasing levels of uniformity and comfort. When evaluating new hazardous area lighting systems, consider both the total system power consumption and the expected luminaire life in order to evaluate energy and maintenance costs and savings.

4. Don’t forget about color temperature options: Do you have a colour temperature preference for your facility? What type of work is being performed and what are the mounting heights of the fixtures? It’s important to remember different colour temperatures create different effects. Cool white has a crisp, bluish appearance, with the highest perceived brightness. It is a great choice for floodlights, especially at higher mounting heights. However, a warmer or neutral colour temperature LED luminaire produces a softer glow and might be a better choice for lower mounted task lights or light fittings.

5. Double check the power system requirements for your facilities hazardous area lighting: What voltages are your hazardous area lights running on? Is your power clean, or is it affected by surges and dips from nearby equipment? New IEEE standards recommend a minimum of 6kV of surge protection for outdoor solid-state lighting, with a recommendation of 10kV for high-risk areas.

6. Research true 1-for-1 retrofit solutions: Is the LED solution you’re considering a true 1-for-1 retrofit for your facility? If not, do you have enough circuits available to add additional fixtures? Labour costs are a major factor in any retrofit lighting project. Being able to mount directly to the existing mounting hoods can save a significant amount of labour time and cost. Ideal retrofit LED solutions allow facilities to utilize existing mounting hoods and conduit/wiring systems, helping to reduce new fixture installation labor costs. Retrofit adapters are often available, allowing fixtures to mate with a wide range of mounting hoods, letting your facility consolidate with a single luminaire.

7. Reconsider facility obstructions: Are there any obstructions in the ceiling that might block light or prevent lighting fixtures from access? Consider alternate mounting means for the lighting fixture, such as pendant mount. For example, Emerson task luminaires have five different mounting hoods to ensure the fixture is installed in the ideal location to properly light the area.

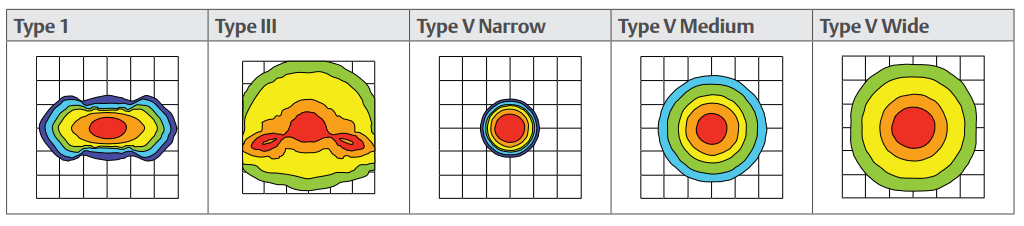

8. Review light levels (IES, RP540): What illumination level are you targeting? Are you following a standard such as IES RP7 for industrial lighting, or API RP540 for petroleum applications? Make sure your lighting layout provides the appropriate illumination level. Most fixture manufacturers have a variety of lumen outputs, so choose the right illumination level to meet the needs of the hazardous area. Too much light can be just as debilitating as not enough. Also remember LEDs are directional, which means you can achieve required light levels with much fewer lumens and watts. For example, a 5,000 lumen LED task light can replace a fixture with a 150W HPS lamp (which generates about 15,000 lumens of light).

9. Evaluate mounting heights: How high do you intend to hang your lighting fixtures? For higher mounting heights, high lumen hazardous area floodlights are a great choice. When mounted higher up on a structure, these floodlights can be used to “wash light” over lower areas, providing uniform general illumination, while minimizing the need for task lighting. Additionally manufacturers that offer field replaceable globes for their fixtures will allow you to retrofit a variety of mounting heights using just one fixture. Globe assemblies can be quickly removed and changed, depending on the application.

10. Assess area locations: Do the locations of your retrofit have hazardous or environmental ratings? What are the area classifications for your retrofit? Are there other certifications or environmental considerations, such as damp locations, marine ratings, or elevated ambient temperatures that your fixtures need to address? When you purchase lighting for a harsh or hazardous industrial location, you need to know that your lights are going to hold up against the environment. Lighting products should be rugged and durable, in addition to meeting all of the certifications and requirements appropriate to your environment, whether it be wet location, marine, hazardous, or harsh industrial.

Lighting | Control Stations | Plugs & Sockets | Junction Boxes | Hazardous Area ATEX Certified Electrical Equipment for Explosive Atmospheres | Zone 1 & Zone 2

Thorne & Derrick | Hazardous Area Equipment & Explosion Protection Specialist Distributors

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

Trace Heating | System Design & Supply