Solenoid Valve Has What It Takes to Survive Harsh Environments

Published 07 Jul 2020

DuPont™ Zenite® LCP liquid crystal polymer helps assure reliability of RedHat Next Generation solenoid valves from ASCO® in exposure to water, aggressive chemicals, hazardous conditions.

Solenoid Valves

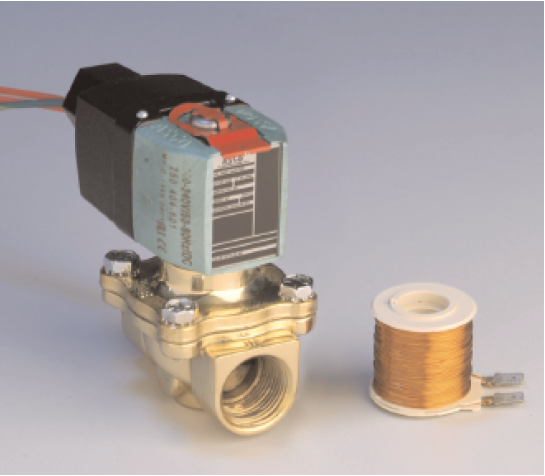

The valve’s solenoid is encapsulated in Zenite® 6130 and has a coil bobbin molded from the same material inside. An earlier model uses thermoset epoxy for encapsulation.

The redesigned valve is ideal for use in hazardous locations, aggressive chemical environments and for indoor and outdoor use where protection is required against splashing water, water seepage, falling or hose-directed water, or severe external condensation, according to ASCO.

The RedHat Next Generation line also delivers a sharp reduction in power consumption. Designed to run on either AC or DC power, a RedHat Next Generation solenoid uses only 2 watts of power to deliver the same performance as a typical 17-watt AC solenoid.

Benefits Gained

- Withstands harsh conditions – The valves are certified for use in hazardous locations and watertight applications as outlined in Class I, Division 2 of the National Electrical Code. In addition, the valves meet all NEMA Types 1 through 4X requirements for water- and dust-tight applications.

- Handles temperature extremes – The solenoid withstands ASCO’s stringent thermal shock testing and can serve at temperatures from -40 to +200ºC.

- Lower production costs – Encapsulation with Zenite® via injection molding costs significantly less than the thermoset epoxy technology used for earlier models. Molding cycles are faster, and sprues and runners are recycled, avoiding waste and disposal costs incurred with thermosets.

- Development assistance – DuPont specialists provided solid technical support to ASCO engineers in part design, tooling and processing.

Material Selected, and Why?

DuPont™ Zenite® 6130 meets this application’s needs for resistance to a wide range of aggressive chemicals, a UL94 V-0 flammability classification, excellent stability and cracking resistance in thermal shock testing and excellent performance in the encapsulation injection moulding process. The resin contains 30% by weight of glass fibre reinforcement.

ASCO Valves

Explosive Atmosphere Experts

Thorne & Derrick are Specialist Distributors of Hazardous Area Electrical, HVAC & Process Instrumentation Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

We supply major UK and international infrastructure projects and also MRO (Maintenance, Repair, Operations) requirements for both planned and unplanned plant shutdowns – we react with a rapid response to customer demand to ensure downtime is minimised and reliable Power, Light & Heat is restored or provided.

We distribute Innovative products to manage the planned replacement of legacy equipment conformant with international classifications including ATEX and IECEx.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

➡ Also Process Instrumentation Products: Ashcroft Pressure Gauges | ASCO Valves | Katronic Flow Meters | KROHNE Flow Meters | VEGA Level Sensors | Rotronic Temperature & Humidity Sensors