Tank Heating | Temperature Maintenance On Tank Containers In Industrial & Hazardous Areas

Published 20 Jan 2021

Tank Heating

Heat Tracing Cables for Tank Heating

Frost Protection For Industrial & Hazardous Areas

In the first of this blog series by Eltherm they will discuss the best electrical trace heating system that will ensure temperature maintenance and freeze prevention for tank heating and containers.

Electrical Heat Tracing made by Eltherm is employed to maintain exact temperatures when transporting temperature-sensitive chemicals in Tank Containers, SWAP Containers, Road Tankers and IBC’s (Intermediate Bulk Containers). Temperature maintenance for tank heating applications is required for substances such as MDI, highly viscous industry materials, oils, resins, fat, coatings, bitumen, adhesives, foods and casting compounds.

Eltherm Tank Container heating systems in operation

Benefits of the eltherm heat tracing system

- Exact temperature maintenance along the entire production and transport chain

- Best possible operational capacity for the entire fleet

- Safe temperature maintain for loading and unloading

- Hitch-free transport operation

- No cold zones, even when cables are damaged

- Quick repair and easy maintenance

- Resistance to moisture and salt water

Control Accuracy for Precise Temperatures

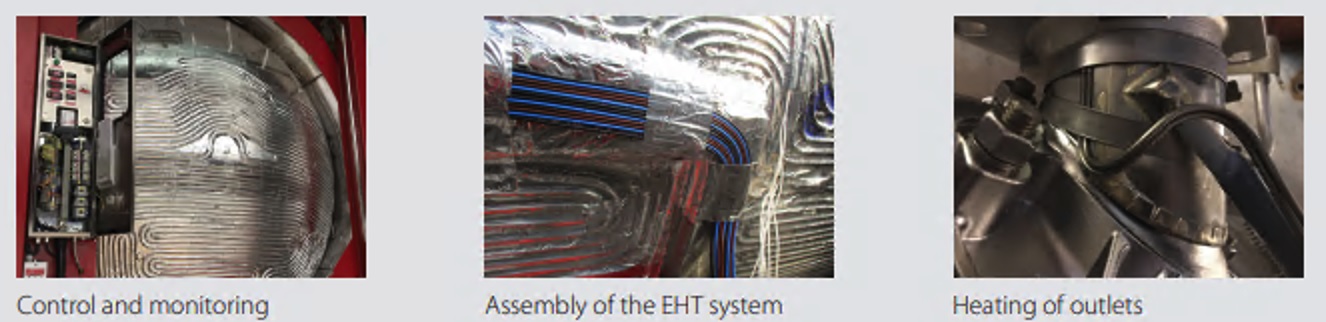

A special assembly technique for EHT on Tank Containers developed by Eltherm engineers plus reliable monitoring and control ensures uniform temperature accuracy across the entire tank surface. It is resistant to vibration impact and thus designed for reliable operation. Apart from the Tank Container itself, the EHT system takes account of outlets, riser pies, including insulating sleeves for valves and ball taps.

Tank Heating Cables | advantages

- Solutions for all sensitive temperatures during transport, storage, loading and unloading at +/- 2 °C

- Standard performance to 18 kW, more electrical performance possible

- Maintenance temperatures with PTFE trace heaters up to 210 °C, with MI trace heaters > 250 °C

- PTFE trace heaters resistant to cargo load temperatures up to 260 °C

- Exact temperature maintenance during storage and transport

- Designed for voltage supply from 220 V to 500 V for global fleet operations

- Heat up of empty tank before cargo loading

- Safe compensation of heat loss on thermal bridges such as support struts

- Light weight of the EHT system, high performance

- Reliable, trouble free operation even during power supply fluctuation during ship transport

- Electrical controllers with hysteresis of +/- 1 °C

- One heating circuit remains operable even when the other is damaged thanks to redundant design

- Repair and easy maintenance of PTFE insulated trace heaters possible anywhere, anytime

- Monitoring and storage of all temperature data along the entire storage and transport cycle

- Tank container for hazardous areas covered by ATEX approval

Electrical Heating Specialists

Thorne & Derrick International, based in the UK, can specify and supply from stock an extensive range of Electrical Heating Equipment for industrial and process heating applications – this includes temperature maintenance and frost protection (Winterisation) products for pipework, valves, IBC’s, drums, hoses, tanks and vessels. We produce custom silicone heaters for rapid and high temperature heat-up of complex shapes and surfaces – from concept, design to the delivery of standard or bespoke heaters on the shortest lead times. From the largest UK heat tracing cable stocks we deliver Electric Trace Heating Systems for pipework frost protection, ramp heating, roof/gutter snow melting and de-icing – enquire about our in-house design service.

Further Reading : Winterisation | Electrical Heating Solutions to Overcome Cold Climate Challenges

EXPERTS IN WINTERISATION SOLUTIONS FOR INDUSTRIAL & HAZARDOUS AREA ENVIRONMENTS

Thorne & Derrick hold the largest UK stocks of frost protection & winterisation equipment to help keep your plant and personnel operational during the winter months.

Thorne & Derrick understand that prolonged periods of low ambient temperatures can bring operations to a standstill costing thousands of pounds in lost downtime.

Experts in heating solutions for use in industrial & explosive atmospheres, Thorne & Derrick have the knowledge & expertise to help clients prevent unnecessary down time this winter.

We can provide overnight delivery of Trace Heating Cables at the most competitive prices to guarantee frost protection of your pipelines and mechanical services.| Ask About Our Heat Trace Design Service.

💡 Contact us today and our skilled and friendly team can provide technical support as well as reliable, fit for purpose and compliant solutions to suit your exact requirements.

Trace Heating | Process Heating | Heating Jackets | Drum & IBC Heaters | Heated Hoses |Silicone Heating Mats

➡See our Winterisation blog TOP PICKS, including our most read articles about Trace Heating and the requirement for electrical heating products and systems to combat and mitigate Winter weather effects.

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery