EN 45545-2 Certification For Amphenol Low Smoke Zero Halogen Inserts

Published 24 Sep 2019

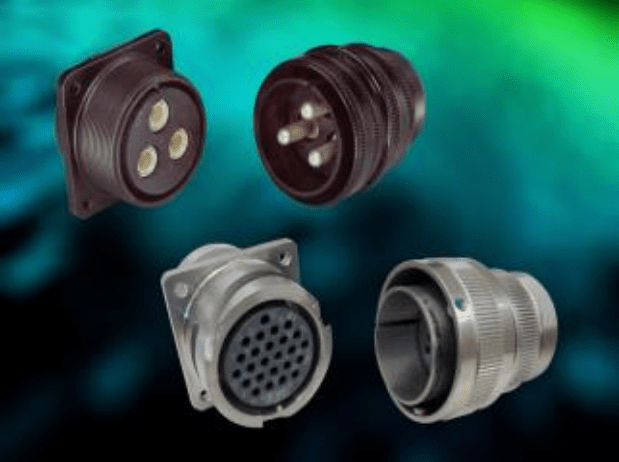

Amphenol GT Series Connectors

- uploaded by Chris Dodds – Thorne & Derrick Sales & Marketing Manager

Amphenol Low Smoke Zero Halogen Inserts

EN 45545-2 Certification

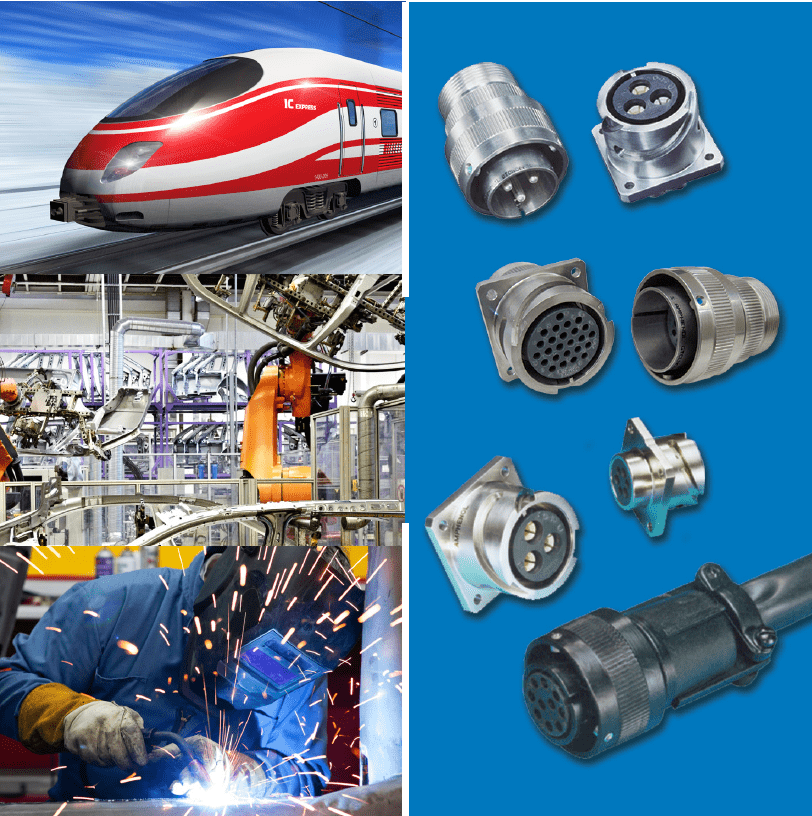

Amphenol Industrial Operations are a worldwide leader in interconnect systems. They have recently received the EN-45545-2 certification for their GT reverse bayonet connector series and 5015 connector series. EN-45545-2 is a certification which defines specific requirements for fire behaviour of materials used to manufacture products used in trains.

The testing process was carried out by SGS, the world’s leading inspection, verification, testing and certification company. The SGS certification process is well known around the world as the benchmark for quality and integrity.

The certification is for the low smoke zero halogen (LSZH) material used in these products.

Mark Cunningham, General Manager at Amphenol Industrial Operations, said, “Qualifying for this EN 45545-2 certification means we’re fulfilling our promise to produce the highest quality connectors. LSZH materials are essential for use in the rail and mass transit market and this shows the technology is meeting the highest standard. We are pleased that we are able to offer our customers the safest and very best products available.”

Low smoke zero halogen

Low smoke zero halogen is a material that is often used in the insert of the connector. When exposed to flames and high levels of heat, LSZH materials produce a very small amount of visible smoke, compared to other materials like PVC; and includes no halogen, which can be harmful to humans.

en 45545-2 classification

EN 45545-2 classifies all material on board trains into groups which have to fulfill specific “Requirement Sets”. These often include various test methods. The test methods included in each Requirements Set are shown in the below.

| Test Methods | R1 | R2 | R3 | R4 | R5 | R6 | R7 | R8 | R9 | R10 | R11 | R12 | R13 | R14 | R15 | R16 | R17 | R18 | R19 | R20 | R21 | R22 | R23 | R24 | R25 | R26 |

| ISO 5658-2 | X | X | X | X | X | X | X | X | ||||||||||||||||||

| EN ISO 5659-2 | 50* | 50* | 50* | 50* | 25** | 50* | 50* | 25** | 25** | 25** | 50* | 50* | 50* | 25** | 25** | 25** | 25** | |||||||||

| ISO 5660-1 | 50* | 50* | 50* | 25** | 50* | 50* | 25** | 25** | 25** | 50* | 50* | 50* | 25** | 25** | 25** | |||||||||||

| EN ISO 9239-1 | X | X | ||||||||||||||||||||||||

| EN ISO 11925-2 | Xª | Xª | Xª | X | X | Xª | Xª | Xª | Xª | |||||||||||||||||

| ISO/TR 9705-2 | X | |||||||||||||||||||||||||

| EN ISO 4589-2 | X | X | X | |||||||||||||||||||||||

| EN 13501-1 | X | |||||||||||||||||||||||||

| ISO 2592/ISO 2719 | X | |||||||||||||||||||||||||

| EN 60332-1-2 | X | X | ||||||||||||||||||||||||

| EN 60332-3-24 or EN 50305 b | X | X | ||||||||||||||||||||||||

| EN 61034-2 | X | X | ||||||||||||||||||||||||

| EN 60695-2-11 | X | |||||||||||||||||||||||||

| EN 60695-11-10 | X | |||||||||||||||||||||||||

| NF X 70-100-1/-2 | X | X | ||||||||||||||||||||||||

| EN ISO 12952-2 | X |

ª Supplementation when, tested in accordance with ISO 5658-2, flaming droplets occur or test result is reported as unclassifiable.

* Irradiance level 50 kW/m 2 , for EN ISO 5659-2 test is conducted without pilot flame.

** Irradiance level 25 kW/m 2 , for EN ISO 5659-2 test is conducted with pilot flame.

amphenol GT Reverse Bayonet connectors

Amphenol GT Connectors with Reverse Bayonet Coupling have been designed according to MIL-DTL-5015 Standard insert patterns. Although these circular reverse bayonet connectors were first used in the military market, they are now the preferred hazardous area connector choice for the mass transit industry and have become a widely used connector for applications in other markets such as aerospace, geophysical and alternative energy.

Businesses in these markets are often based within or around hazardous area locations, and require a reliable connector that can survive the harshest environments while still supplying high current power and signal.

With such a large variety of design options available such as shell styles, insert configurations, and backshells, the GT connector offers a wide range of choices for a wide range of applications.

Features & Benefits

- Rugged aluminum or stainless steel shell styles

- Variety of additional shell platings available

- Crimp and solder contacts available with silver or gold plating

- Inserts with Neoprene or optional low smoke material or Viton material

- Operating temperature: Neoprene/low smoke -55°C to +125°C; Viton -50°C to +200°C

- Audible, tactile, and visual indication of positive coupling

- 2000+ mating cycles

- High shock and vibration resistance

- No lockwiring necessary

- Low Smoke and Fluid Resistant inserts available

Specifications

- UL #E115497

- EN 45545-2

- IP67 Rating

Explosion Proof & Hazardous Area Connectors | ATEX | IECEx

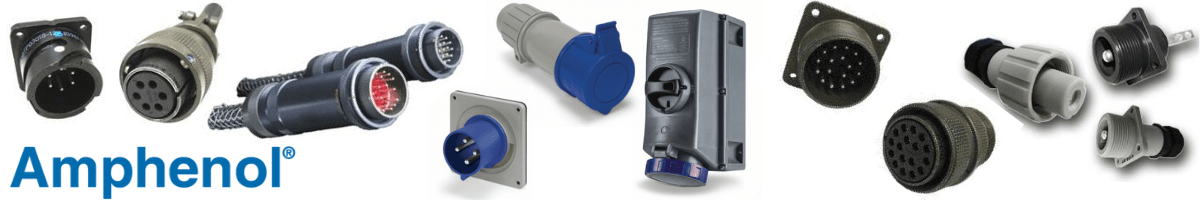

Amphenol Connectors For Industrial & Harsh Environments | Amphe-309 | Star-Line | Amphe-Lite | GT | 5015 | Amphe-SP3

Amphenol Hazardous Area Connectors | Amphe-Ex | Amphe-Coal EX | EX309 | Rig-Power | Star-Line EX | Amphe-Mine EX

LV HV Electrical & Process Instrumentation Equipment for Explosive Atmospheres

Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications – we react with a rapid response to your enquiry to ensure downtime is minimised and reliable Power, Light & Heat is restored or provided.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Control Stations | Motor Starters | Heat Trace Cables & Trace Heating Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters | Process Instrumentation

Electrical Power LV HV | Heating | Lighting | Process Instrumentation | EX Specialists

Further Reading

-

Amphenol Low Smoke Zero Halogen Inserts

Size: 3.52 MB

Amphenol Low Smoke Zero Halogen Inserts

Size: 3.52 MB