Hazardous Area Connectors For Mining | Amphenol Amphe-Mine EX

Amphenol Amphe-Mine EX Hazardous Area Connectors

Hazardous Area Connectors

Amphenol Amphe-Mine EX | ATEX & IECEx Connectors

Underground Mining | Explosion Proof

Amphenol Amphe-Mine EX series of hazardous area connectors is a hybrid form of the parent Amphenol Star-Line range. The series holds many certifications such as ATEX, IECEx, AEx, Canadian EX and GoST-R.

In addition to these hazardous area classifications, Amphenol has added Australian Group I Mining approval. This new certification is through TUV Rheinland, and meets the IECEx listing for Group I applications in Australia.

The modern mining industry has enormous electrical challenges. Electronics used in today’s mines and mining equipment must be able to manage more power, handle higher voltages, move data and communication transmissions faster, and operate without interruption in some of the world’s harshest environments. Amphenol has solutions to solve these technical challenges.

Amphenol Amphe-Mine EX connectors are ideal for use in applications such as:

– Asset location systems for underground mining applications

– Onshore and Offshore based Oil & Gas drilling platforms

– Pharmaceutical & Chemical processing plants

– Turbines

– RMT Intercar Jumpers

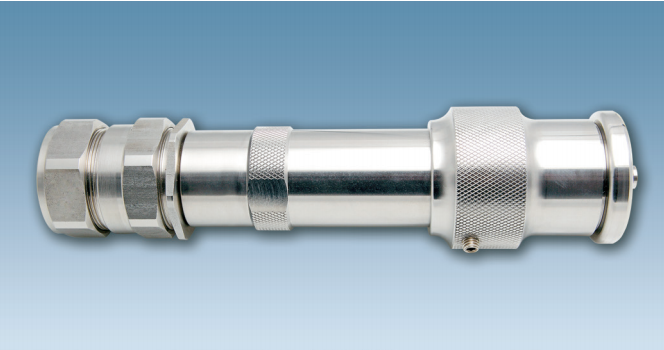

This series of cylindrical, Stainless Steel, threaded coupling power and signal connectors for use in harsh environments and hazardous areas within the underground mining industry includes male plugs, female inline receptacles, female panel mount receptacles, panel mount circular flange receptacles and thru bulkhead-dual mate receptacles. Connector shells are available in sizes 12, 16, 20, 24, 28, C20, C24 & C28.

Amphenol Hazardous Area Connectors | Amphe-Ex | Amphe-Coal EX | EX309 | Rig-Power | Star-Line EX | Amphe-Mine EX

Amphe-Mine EX specification

Amphenol Amphe-Mine EX connectors are manufactured from rugged, high grade components and is available in various temperature ratings – T4, T5 & T6, according to IECEx standards.

There are a vast array of insert varieties to suit almost any conductor count or cable style, including VFD, IEEE/UL1309, IEC, BS, DIN and JIC or flexible cables such as SOOW-A, W. G-GC and DLO.

A wide variety of ATEX cable glands are also available for back-end wire termination, including both armoured or unarmoured cables.

Hazardous Area Connectors – Features

- Underground mining explosive proof design

- Hazardous area, environmental connector IP68-8

- Large coupling sleeve, secured with captive set screws

- Double lead threaded coupling system

- Rated for use up to 1000 VAC

- With EEx d (Flameproof) Cable Glands

- Vast family of inserts, for power, signal and mixed applications

- Five different shelf sizes with a number of insert combinations

- 18, 16, 12, 10, 8, 4, 1/0, 4/0 AWG / 350, 500, 535, 646 & 777 MCM

- Extensive array of hardware & strain relief options

- RADSOK® with a current rating up to 1135 Amps

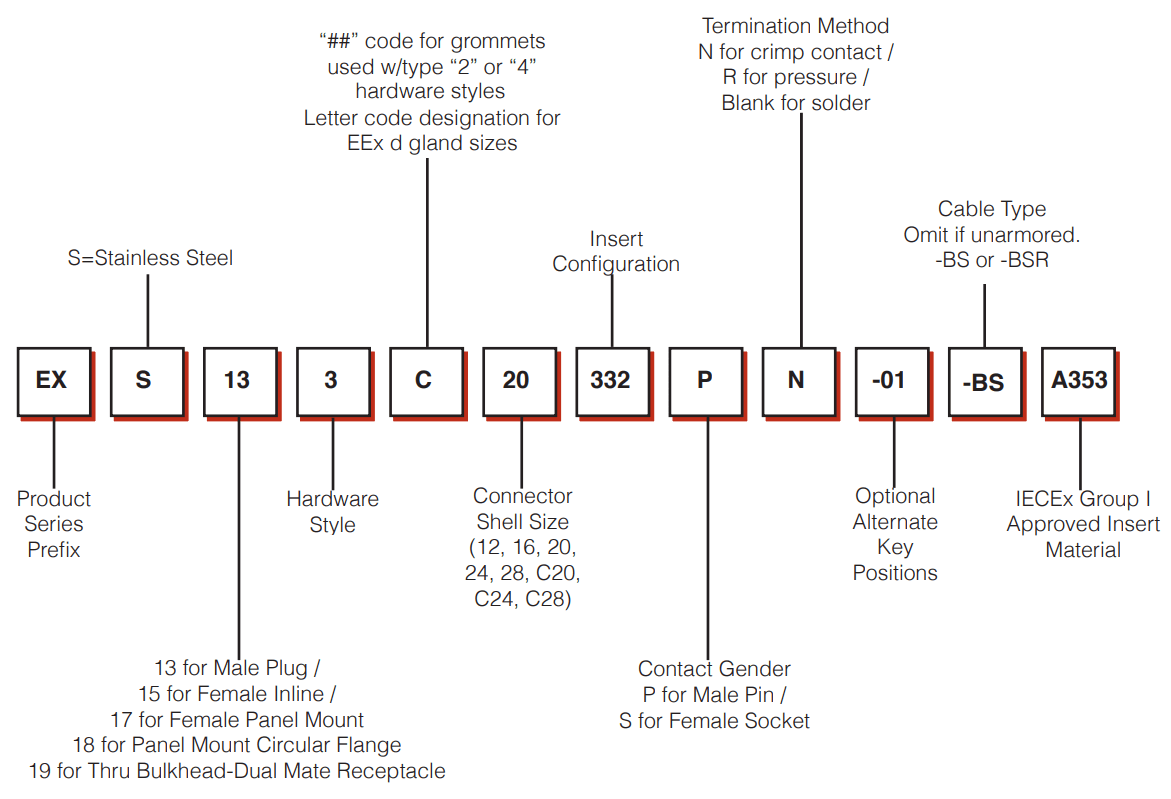

How to Order Amphenol Amphe-Mine EX

➡ Call our expert sales team for advice.

Amphenol Amphe-Mine EX | How to Order

| Example Part Numbers | Hazardous Area Connector Description |

| EXS-13-3-C-20-332PN-BSA353 | Plug w/ cable gland for armoured cable |

| EXS-15-3-C-20-332SN-BSA353 | Inline receptacle with cable gland for armoured cable |

| EXS-17-1-20-332SNA353 | Panel/Box Mount receptacle, potting required |

hazardous area certifications

- RoHS

- ATEX

- IECEx

- AEx

- Canadian EX

- GoST-R

- Australian IECEx Group I Certified

Amphenol Connectors For Industrial & Harsh Environments | Amphe-309 | Star-Line | Amphe-Lite | GT | 5015 | Amphe-SP3

EXPLOSION PROOF & HAZARDOUS AREA ELECTRICAL EQUIPMENT

Integrity | Knowledge | Reliability | Electrical HVAC Process Instrumentation Equipment

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are leaders in the development and distribution of ATEX & IECEx Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Panels | Plugs | Isolators | Enclosures | Lighting | Control Stations | Motor Starters | Call Points | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Fans | Security Locks

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery