Modular V Sealed For Life | Maintaining Ex Lighting | What Is The Difference? – Part 1

Published 18 Nov 2019

Modular VS Sealed For Life

Modular V Sealed For Life

Maintaining Ex Lighting

Part 1 – What’s the Difference?

In this 4-part series, Raytec compare between ‘modular’ and ‘sealed for life’ LED Ex luminaires, and how the design and certification of these different approaches impacts how easily maintenance can be carried out. In this first installment, we’ll look at what we actually mean by ‘modular’ and ‘sealed for life’ and identify the key differences in how these solutions have been designed.

Maintenance is an important consideration for lighting in hazardous areas. It is required to ensure the light fittings are compliant and are operating at their optimum. Maintenance can be tricky and expensive however by choosing an LED solution reduces downtime due to maintenance. It is worth noting that as with all hazardous area applications unscheduled maintenance checks are still a possibility.

Ensuring maintenance of the ex lighting can be carried out as swiftly and as simply as possible is therefore an important consideration. So the question is how do you know whether a luminaire is easy to maintain or not? Simply put, Ex luminaires can be categorised in two ways;

Sealed for Life Luminaires – Many Ex lighting solutions are factory sealed (or encapsulated), primarily as a method of protection (as part of the light fitting hazardous area certification). Once sealed, the luminaire cannot be opened up and internal components cannot be accessed, i.e. ‘sealed for life’.

This design in terms of certification is recognised as a simple method of gaining ex approval but does have some drawbacks. For instance the factory seal can’t be opened without rendering the certification null and void and this is a critical part of the ex lighting’s hazardous area rating. Opening the unit could cause an explosion as the fitting would no longer be suitable for use in hazardous areas. As a result, maintenance of a sealed for life luminaires is very limited.

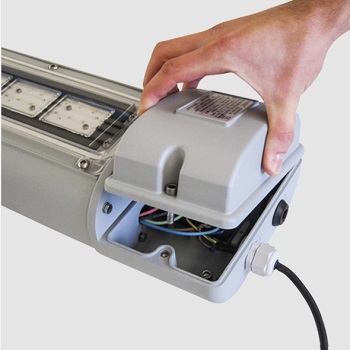

Modular Luminaires – In contrast, ‘modular’ luminaires are specifically designed in a way which allows them to be opened up and accessed for maintenance, without invalidating certification.

This is due to the fact the light fitting’s hazardous area rating isn’t linked to being factory sealed. While encapsulation may still form a part of the certification, this is likely to be at a component level (such as encapsulated drivers), rather than the entire luminaire. Without this restriction, maintenance becomes much easier and components can be changed or inspected without invalidating the luminaire’s certification.

Now we’ve established how the design and certification of Ex luminaires can be different, and how it impacts the ease of maintenance, the next question is, ‘Why is maintenance so important?’

In Part 2, Raytec look at downtime during maintenance, and how the design of these two solutions will affect the length of time a user is likely to be left without light during a common maintenance procedure.

Further Reading

Modular V Sealed For Life | Maintaining Ex Lighting | Downtime – Part 2

Modular V Sealed For Life | Maintaining Ex Lighting | Environmental Impact – Part 3

Modular V Sealed For Life | Maintaining Ex Lighting | Cost – Part 4

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: ATEX Doors | Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

Trace Heating | System Design & Supply