Modular V Sealed For Life | Maintaining Ex Lighting | Downtime – Part 2

Published 11 Nov 2019

Modular VS Sealed For Life

Modular V Sealed For Life

Maintaining Ex Lighting

Part 2 – Downtime

In this four-part series, Raytec compare ‘modular’ and ‘sealed for life’ LED Ex luminaires, and how the design and certification of these different approaches impacts how easily maintenance can be carried out.

In the second blog of the series Raytec look at how the design affects downtime during a routine maintenance check. Let’s consider this in the context of a real scenario;

Application: Offshore, Oil Rig

Scenario: A luminaire installed on the rig has failed and is no longer producing a light output.

Cause: A failure of the luminaire’s PSU/driver.

Total or partial loss of light is common when a PSU fails. This could cause devastating consequences for the worker and all current operations will be halted causing major cost implications. A quick solution is urgently required.

Sealed for Life Luminaire

After a PSU failure the engineers on the rig can’t solve the problem if the luminaire is sealed as this would nullify the certification.The luminaire must therefore be returned to the manufacturer.

The luminaire must be removed, the relevant paperwork must be raised, and arrangements to return back to the manufacturer. Hopefully the ex lighting will be fixed asap but the rig will still be without

At best, the manufacturer will be proactive in replacing the luminaire, but the affected area of the rig will still be left without a light for a period until the replacement arrives. At worst, the manufacturer will ask for the luminaire to be returned and inspected before any corrective action is taken, meaning the rig will be left without light for longer.

Either way, a significant period is likely to pass until light can be restored.

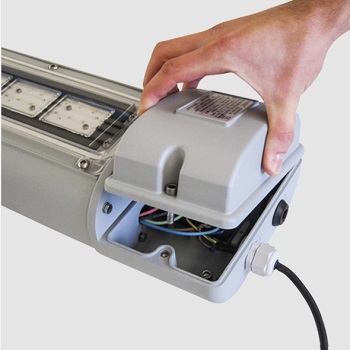

Modular Luminaire

Conveniently modular ex lighting can be maintained on site as the internal components can be accessed without causing invalidation to the certification.

These components are also interchangeable so spare parts can be kept on-site to service the unit. The light can therefore be repaired so there is minimal disruption to operations as the rig’s engineers are able to change the PSU/driver quickly.

With the understanding that a sealed for life luminaire must be returned to the manufacturer, in part 3 we will consider how this, and other features of a luminaire, can impact the environment. Look out for Part 3 ‘Modular vs. Sealed for Life: Environmental Impact’

Further Reading

Modular V Sealed For Life | Maintaining Ex Lighting | What Is The Difference? – Part 1

Modular V Sealed For Life | Maintaining Ex Lighting | Environmental Impact – Part 3

Modular V Sealed For Life | Maintaining Ex Lighting | Cost – Part 4

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: ATEX Doors | Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

Trace Heating | System Design & Supply