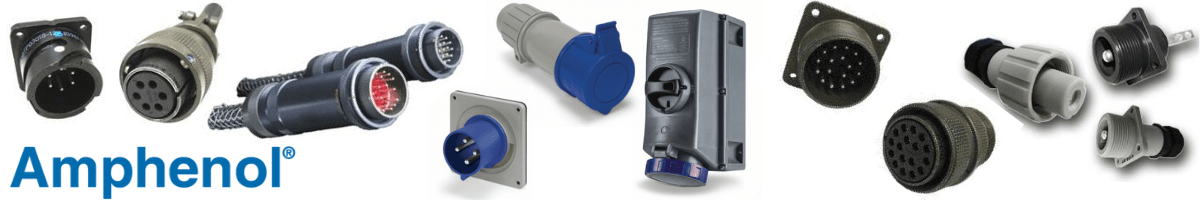

Industrial Plugs & Sockets | Amphenol GT Reverse Bayonet Connectors

Amphenol GT Reverse Bayonet Coupling Connectors

Amphenol GT

Industrial Plugs & Sockets

Amphenol GT Reverse Bayonet Coupling Circular Connectors with SAE AS50151 Insert Patterns.

Amphenol GT are rugged, versatile and environmentally resistant connectors. Designed with MIL-DTL-5015 insert patterns in mind and originally for use by the military, the heavy duty GT connector has become widely used in commercial, geophysical, aerospace, ground support and shipboard applications. It is the preferred connector for mass transit.

These markets require a reliable connector which is able to supply high current power and signal to the harshest of environments. With a vast variety of shell styles (Aluminium or Stainless Steel), insert configurations, and backshells, the GT connector offers a robust possibility of design choices.

Amphenol offers Amphe-Power Connectors, high amperage capability connectors designed for the most demanding industrial and transportation applications. Part of the Amphe-Power range, the GT connectors, in most shell styles, can be enhanced with RADSOK contacts that handle up to 150% higher amperages than standard contacts. The RADSOK contact is a hyperbolic, stamped grid configuration within the socket.

As the male pin is inserted, axial members in the female half deflect, imparting high current flow across the connection with minimal voltage loss. This design ensures a large, coaxial, face-to-face surface area engagement and provides higher current capacity with minimised temperature rise.

The strongest benefit of RADSOK is its very low mill-volt drop because of the intimate contact provided by the spring force of the grid. RADSOK contacts are available in size 8 (69 amps), size 4 (120 amps), and size 0 (250 amps).

Current Amphe-Power lines support from 50A to 500A continuous duty. Hybrid arrangements with RADSOK and power contacts can be tailored to meet customer needs.

Amphenol GT connectors range include: GT Amphe-Power Connectors with RADSOK technology, the GTC-M Series with metal clip inserts and GT-PC Series for high voltage power applications.

Amphenol Hazardous Area Connectors

Amphe-Power Amphe-GTR

The Amphe-Power™ GT series provides the benefit of a GT connector in a high performance composite material. The GT-R is listed to UL/CUL 2238 Standard, Control Number 19VP. It also

meets all of the specifications for high power process control and server applications.

Performance level is the same as that of the GT series. RADSOK contacts enable an increased current rating of 120A on individual contacts, and a standard PG thread achieves an IP67 seal rating. Compression (setscrew) wire termination to the 4/6AWG or 8/10AWG conductors allows for easy field replacement of pin or socket contacts. It also provides for easy complete plug or receptacle assemblies, all without a need for specialised tooling.

Power GT

The Power GT is a modification to the GT series incorporating three 8.0mm RADSOK contacts mounted in a common termination to busbar or cable, enhanced to an ultra-high current density in a compact shell size 28 layout.

This design created the first TUV “finger-proof” 500A connector in the marketplace with the “dead-front” pin design to prevent contact with live circuits. In

environmental versions, this connector achieves IP67 performance.

The ninety-degree wire orientation on the plug provides low-profile mounting for tight packaging requirements. This plug is designed to be over-molded, and can also be fitted with mechanical hardware for individual requirements.

GTC-M Series – The GT with Metal Clip Inserts

Amphenolʼs GTC-M series combines the GT reverse bayonet connector and the rear release metal clip retention system which is used in the Amphenol®/Matrix® MIL-C-5015 connector line.

Another benefit is the captivated coupling nut assembly which allows unmating without the rear accessories attached. Improved environmental sealing is achieved with this series. The crimp joint is covered by a three-webbed fluorinated silicone grommet that seals on the wires without the necessity of an additional sealing clamp. An interfacial seal with conical towers on the pin insert matches with recesses on the socket; a match that provides the popular “cork and bottle” seal during mating. The grommet and the interfacial seal provides adequate sealing during environmental extremes. The GTC-M series is intermateable and intermountable with the standard GT series, and it uses standard M85049 style rear accessories. For more information on the GTC-M Series,

request Product Data Sheet #181.

GT-PC Connectors for High Voltage Power Applications

The Amphenol® GT-PC connectors were developed for use in the High Voltage Power Distribution industry. Incorporating all the standard features of the popular GT series, these connectors will

prevent accidental electrical shocks to the technicians.

“Dead Front” pin contacts in size 0 are recessed into a socket insert, preventing inadvertent contact with a live circuit. Higher amperage levels are provided – up to 100 amps per contact. The GT-PC series has been UL approved.

“First Mate – Last Break” features on one or more of the pins provide an additional measure of operator safety. Currently there are 5 insert patterns available. Consult T&D for more information.

GT Connectors for the HMI Lighting Industry

Amphenol provides GT connectors for the rugged use experienced during stage shows and other entertainment events, even outside in the elements.

The same 3-point bayonet coupling system and the same ruggedness to survive 2000 mating cycles are provided. The unique features of this connector series include color-coded receptacle shells with matching backshells on the cable plugs.

The colors can be matched to specific wattage cables and/or light systems. A wide selection of environmental adapters designed to seal on the outside diameter of specific cable diameters can be fitted to the backshells. Applications for these connectors include power and control of lighting trusses, and portable power and dimmer racks. For more information contact T&D.

ARCL Series

Amphenol has developed a heavy duty 5015 type connector with 38999 Series III type coupling for use in mass transportation and heavy equipment applications. The ARCL Series has the same

electrical characteristics as 5015 standard product but it has rugged ratchet double start stub threads. These rugged double stub threads eliminate mis-mating and provide for easy cleaning.

Other features/benefits of the ARCL connector series:

- 5 key/keyway alignment feature.

- Operating temperature is from –55°C to +125°C. Operating voltage is to 3000 VAC (RMS) at sea level.

- Crimp and solder termination available.

- 5 shell styles with all the 5015 insert patterns available.

- Supplied with low smoke, low halogen inserts which are flame retardant, but also can be supplied with standard 5015 inserts.

- Wide variety of backend accessories for all styles of cable and conduit, and a variety of cable strain reliefs including over-molding and heat shrink boots.

- RADSOK high amperage sockets can be incorporated.

Amphenol GT Connectors

features & benefits

- Quick positive coupling

- Crimp and solder contacts available with silver or gold plating

- Audible, tactile and visual indication of full coupling

- Waterproof – IP67 rated

- No lock wiring required

- High shock and vibration capabilities

- Inserts available in Neoprene and Viton materials

- Low smoke/flame retardant inserts also available

- Operating temperature range: With Neoprene inserts: –55°C to +125°C | With Viton inserts: –50°C to +200°C | With low smoke/flame retardant inserts: –55°C to +125°C

- Available in both crimp and solder terminations

- Contacts available in gold and silver plating

- Numerous commercial finishes available

- Zinc alloy plating (cadmium free) available

- Rugged construction; aluminium or stainless steel components

- Available with resilient cover coupling for added damage protection and increased gripping surface

- Inter-mateable with existing VG95234 connectors

- 2000 couplings minimum

- UL recognised

- Up to 50% more ampacity with the use of RADSOK technology

Specification

- UL #E115497

- EN 45545-2

- IP67 Rating

Amphenol Connectors For Industrial & Harsh Environments | Amphe-309 | Star-Line | Amphe-Lite | GT | 5015 | Amphe-SP3

Amphenol Hazardous Area Connectors | Amphe-Ex | Amphe-Coal EX | EX309 | Rig-Power | Star-Line EX | Amphe-Mine EX