SICK ZIRKOR302 | In-Situ Gas Analysers For Oxygen Measurement

In-Situ Gas Analyser

SICK ZIRKOR302

The Other Kind Of Oxygen Measurement

The ZIRKOR302 in-situ gas analyser from SICK can be relied upon to measure oxygen quickly even at increased temperatures. The flow sensor measurement principle and fully automated calibration using ambient air means it does not require expensive test gases.

The Zirconium Dioxide oxygen analyser is not an ignition source in the gas detection process thanks to its safety-related design and construction which are compliant with national legal requirements of TuV, GOST and KAITEC, regarding the measurement of oxygen levels in flue gas.

Typical Applications for SICK ZIRKOR302

- Reference value formation during emission monitoring

- Monitoring of oxygen surpluses

- Monitoring of inert gas atmospheres

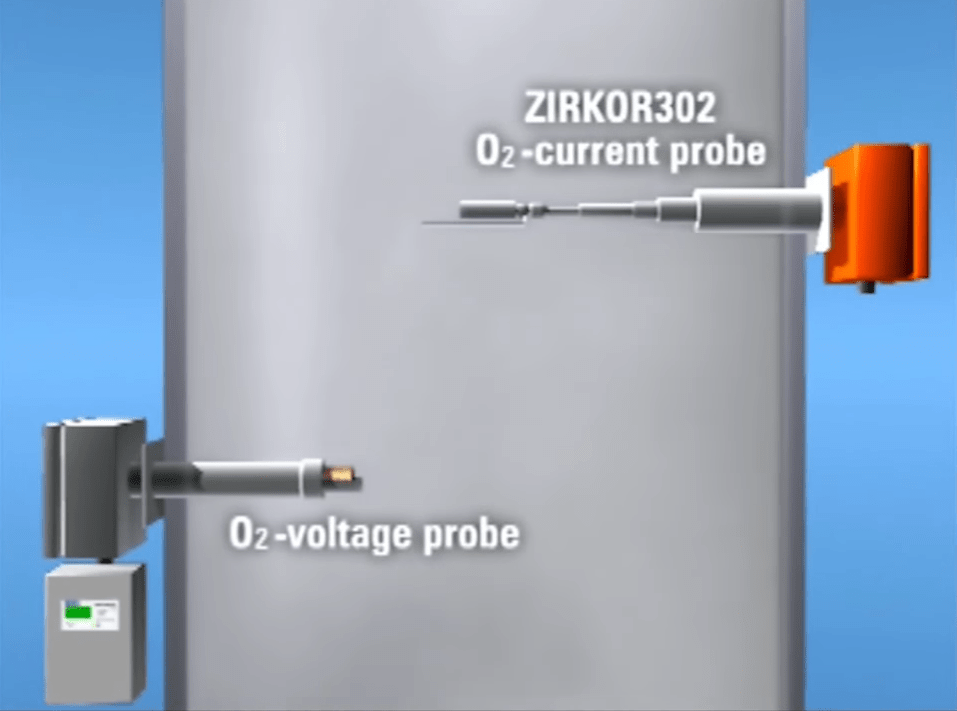

In-Situ Gas Analysers | SICK ZIRKOR302 v O2 Voltage Probe

➡ The video below compares the SICK ZIRKOR302 gas analyser, which uses the Zirconia current principle, with a standard O2 voltage probe in-situ gas analyser.

SICK ZIRKOR302 Gas Analyser

Features

- Innovative flow sensor measurement principle

- Fixed physical zero point and linear measurement signal

- All parts in contact with gas are heated

- Version for high temperatures available

- Short response time

- Operation of up to three analysers via one evaluation unit

SICK ZIRKOR302

Technical SPECIFICATION

SICK ZIRKOR302 analyser unit

Please note: The exact device specifications and performance data of the product may deviate from the information provided here, and depend on the application in which the product is being used and the relevant customer specifications.

| ZIRKOR302 E Analyser Unit | ZIRKOR302 P Analyser Unit | |

| Description | Analyser with ejector operating with compressed air | Analyser with integrated sample gas pump |

| Measured Values | O2 | |

| Performance-Tested Measurands | O2 | |

| Measurement Principles | Zirconium dioxide current sensor | |

| Gas Flow Rate | 0.5 l/h | |

| Measuring Ranges | 0 … 10 Vol.-% / 0 … 25 Vol.-% | |

| Certified Measuring Ranges | 0 … 21 Vol.-% | |

| Response Time (t90) | ≤ 20 s (With standard gas sampling device, length = 1 m) | |

| Zero Point Drift | ≤ 0.2 Vol.-%: within the maintenance interval | |

| Reference Point Drift | ≤ 0.2 Vol.-%: within the maintenance interval | |

| Process Temperature | Stainless steel probe: 0 °C … +700 °C Inconel probe: 0 °C … +950 °C Ceramic probe: 0 °C … +1,400 °C |

|

| Process Pressure | 700 hPa … 1,100 hPa | |

| Process Gas Humidity | Non-condensing | |

| Ambient Temperature | –20 °C … +55 °C | |

| Storage Temperature | –40 °C … +85 °C | |

| Conformities | Approved for plants requiring approval: EN 14181 2000/76/EC (17. BImSchV) 2001/80/EC (13. BImSchV) 27. BImSchV |

|

| Electrical Safety | CE | |

| Enclosure Rating | IP65 / NEMA 4x | |

| Analog Outputs | 1 output: 0/4 … 20 mA, + 800 Ω 0 … 10 V Potential-free; extendible by an additional I/O module |

|

| Digital Outputs | 4 relay contacts: + 48 V AC, 1 A, 30 W / 48 V DC, 1 A, 60 W Option |

|

| Digital Inputs | 4 inputs: + 24 V Option |

|

| Indication | LC display | |

| Input | Functional keys Arrow keys |

|

| Operation | Menu-driven operation via LC display and membrane keyboard | |

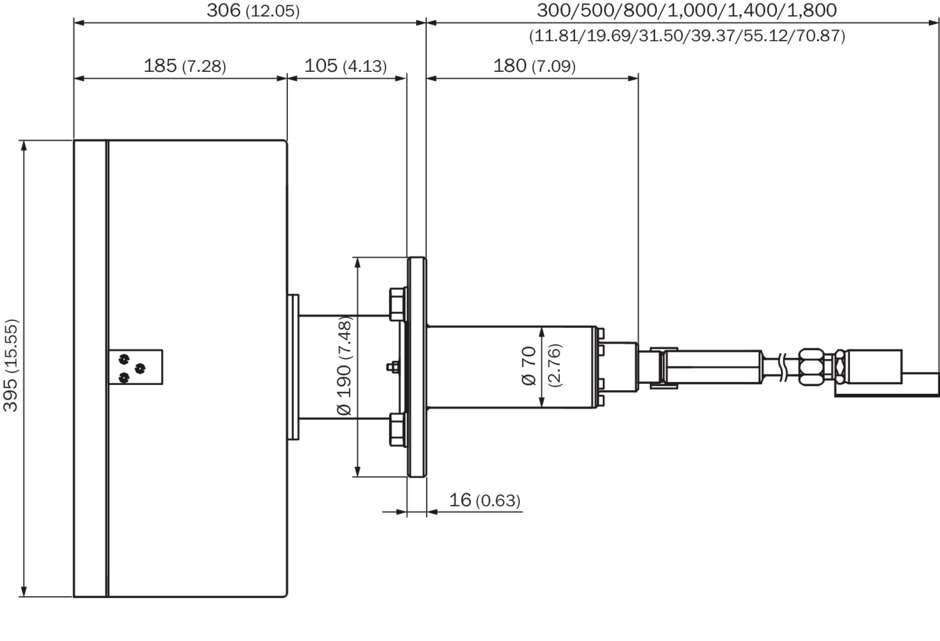

| Dimensions (W x H x D) | Dimensions may vary. See data sheet | |

| Weight | 27 kg (With standard gas sampling device, length = 1 m) With heating for gas sampling device, additional: 4 kg … 6 kg |

|

| Material In Contact With Media | Stainless steel 1.4571 | |

| Power Supply | Voltage: 115 V//230 V Frequency: 48 … 62 Hz Power consumption: ≤ 250 W |

|

| Auxiliaries | Compressed air: 4 … 6 bar; particle size max. 1 µm; oil content max. 0.1 mg/m³; pressure dew point max. –30 °C | X |

| Corrective Functions | Automatic testing and adjustment with ambient air | |

| Integrated Components | Sample gas pump | |

SICK ZIRKOR302 Analyser Unit

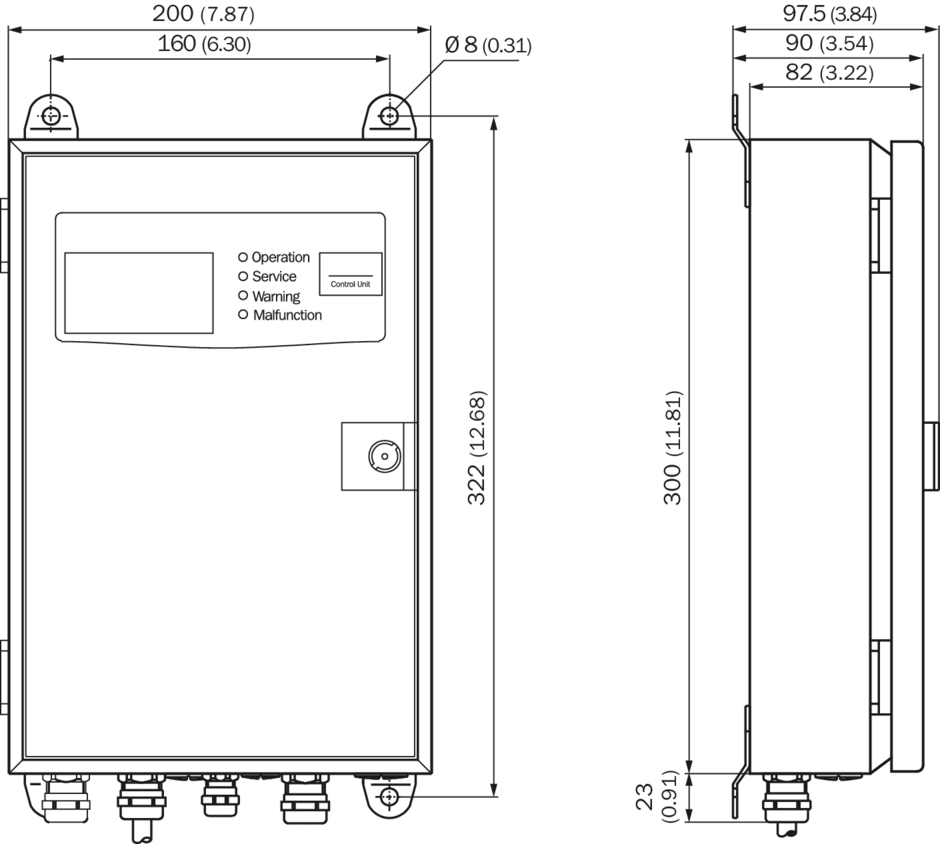

SICK ZIRKOR302 Control Unit (Sheet Steel Housing)

| Description | The control unit serves as the human machine interface and is responsible for data processing and output as well as control and monitoring functions. |

| Enclosure Rating | IP65/NEMA 4x |

| Analog Outputs | 3 outputs: 0/4 … 20 mA, + 500 Ω Electrically isolated; one measured value output per connected analyser |

| Digital Outputs | 2 relay contacts: + 150 V AC, 1 A, 60 W / 125 V DC, 1 A, 30 W |

| Digital Inputs | 3 inputs: + 24 V (Pre-set for failure, maintenance and functional control) |

| Communication Interface | Serial CAN bus Type of fieldbus integration: RS-232 Function: Connection to SOPAS ET software Internal system bus |

| Number | 1 |

| Indication | LC display Status LEDs: “Power,” “Failure,” and “Maintenance request” |

| Input | Arrow keys & Functional keys |

| Operation | Menu-driven operation via LC-display and membrane keyboard |

| Model | Steel sheet enclosure |

| Dimensions (W x H x D) | 200 mm x 346 mm x 97.5 mm |

| Weight | 4 kg |

| Power Supply | Voltage: 115 V/230 V Frequency: 50 Hz/60 Hz Power consumption: ≤ 50 W Recommended pre-fuse: 10A |

Control Unit (Steel Sheet Enclosure) | SICK ZIRKOR302

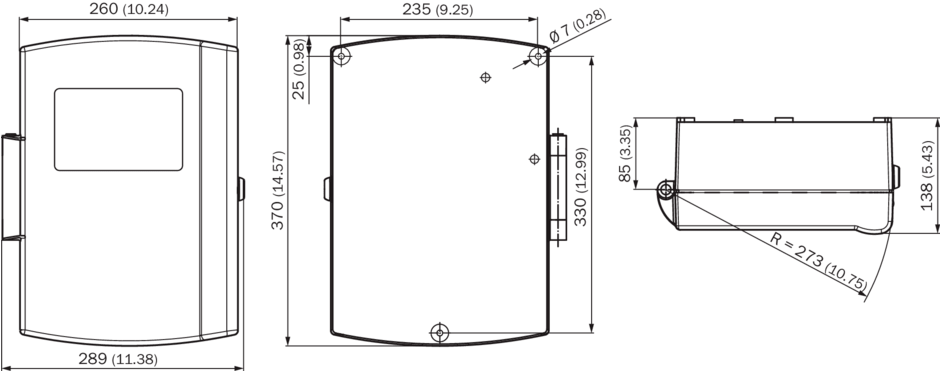

SICK ZIRKOR302 Control Unit (cAST Metal Housing)

| Description | The control unit serves as the human machine interface and is responsible for data processing and output as well as control and monitoring functions. |

| Enclosure Rating | IP67/NEMA 4x |

| Analog Outputs | 3 outputs: 0/4 … 20 mA, + 500 Ω Electrically isolated; one measured value output per connected analyser |

| Digital Outputs | 3 relay contacts: + 48 V AC, 1 A, 60 W / 48 V DC, 1 A, 30 W Pre-set for failure, maintenance and functional control |

| Digital Inputs | 3 inputs: + 24 V |

| Communication Interface | Serial CAN bus Type of fieldbus integration: RS-232 Function: Connection to SOPAS ET software Internal system bus |

| Number | 1 |

| Indication | LC display Status LEDs: “Power,” “Failure,” and “Maintenance request” |

| Input | Arrow keys & Functional keys |

| Operation | Menu-driven operation via LC-display and membrane keyboard |

| Model | Cast metal enclosure |

| Dimensions (W x H x D) | 200 mm x 346 mm x 97.5 mm |

| Weight | 4 kg |

| Power Supply | Voltage: 115 V/230 V Frequency: 50 Hz/60 Hz Power consumption: ≤ 50 W Recommended pre-fuse: 10A |

SICK ZIRKOR302 Control Unit (Cast Metal Enclosure)

Gas, Liquid & Bulk Solids Sensors, Analysers & Detectors from SICK

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES & Hazardous Areas

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters