Chromalox SRM/E Self-Regulating Trace Heating Cable (Medium Temperature – 302°F 150°C)

Frost Protection Trace Heating Cables

Trace Heating

Chromalox SRM/E self-regulating trace heating cables provide process temperature maintenance and frost protection to pipework, instrument lines, tanks and drums up to 150º Celsius. They are Factory Mutual (FM) Approved, UL Listed, and CSA certified for ordinary areas. ATEX, IECEx, FM, and CSA Approved for hazardous areas when.

Trace Heating Cable Features

- Chromalox SRM/E trace heating cables are energy efficient as they use less energy when less heat is required

- The simple to install heating cable can be cut to any length while in the field (see max circuit length)

- SRM/E trace heating cables offer low installation costs and require less maintenance minimising downtime

- Heating cables can be single overlapped without burnout, which simplifies heat tracing of in-line process equipment such as valves, elbows and pumps

- The risk of overtemperature is minimised with self regulating trace heating cables

- Chromalox cable termination, splice, tee and end seal kits further reduce installation time

Trace Heating Cable | Frost Protection for Pipes

trace heating CABLE – SPECIFICATION

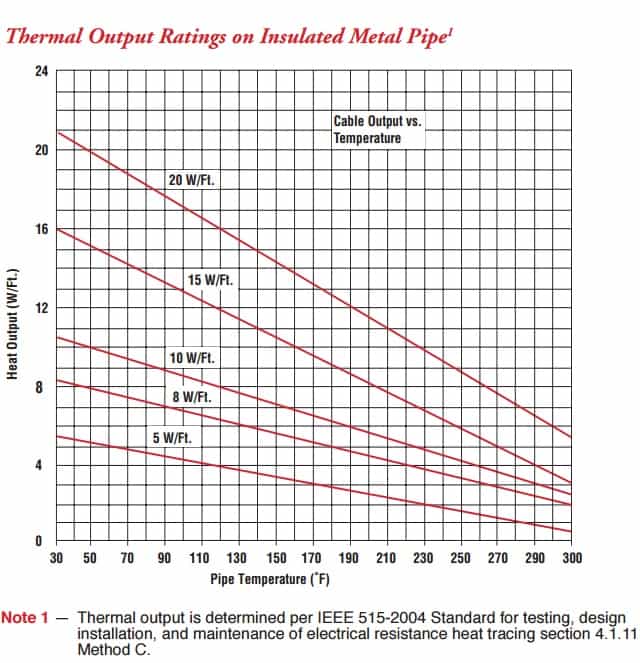

Chromalox SRM/E heat trace cable wattages per metre at 10°C – 5, 8, 10, 15 and 20 watts. This range of self-regulating trace heating cables increase power output as temperatures fall, to provide guaranteed frost protection and temperature maintenance of industrial process and water pipework.

- Approximate Heating Cable Size : 3/8″ W x 1/8″ H

- Maximum Maintain Temperature : 150° Celsius

- Maximum Continuous Exposure Temperature : Power Off 215° Celsius

- Available Models (Voltages) : 120 and 208 – 277V

- Minimum Heating Cable Bend Radius : 1-1/8″

- Trace Heating Cable Circuit Lengths : Up to 750 feet

| Chromalox Cable Part Number | Trace Heating Cable Description | W/Ft | Voltage |

| 385490 | Chromalox SRM/E-3-2C | 3 |

240V |

| 385561 | Chromalox SRM/E 3-1CT | 120V | |

| 385570 | Chromalox SRM/E 3-2CT | 240V | |

| 388025 | Chromalox SRM/E-3-1C | 120V | |

| 388084 | Chromalox SRM/E-5-1C | 5 |

120V |

| 388092 | Chromalox SRM/E 5-1CT | 120V | |

| 388113 | Chromalox SRM/E-5-2C | 240V | |

| 388121 | Chromalox SRM/E 5-2CT | 240V | |

| 388148 | Chromalox SRM/E-8-1C | 8 |

120V |

| 388156 | Chromalox SRM/E 8-1CT | 120V | |

| 388172 | Chromalox SRM/E-8-2C | 240V | |

| 388180 | Chromalox SRM/E 8-2CT | 240V | |

| 388201 | Chromalox SRM/E-10-1C | 10 |

120V |

| 388210 | Chromalox SRM/E 10-1CT | 120V | |

| 388236 | Chromalox SRM/E-10-2C | 240V | |

| 388244 | Chromalox SRM/E 10-2CT | 240V | |

| 388260 | Chromalox SRM/E-15-1C | 15 |

120V |

| 388279 | Chromalox SRM/E 15-1CT | 120V | |

| 388308 | Chromalox SRM/E-15-2C | 240V | |

| 388316 | Chromalox SRM/E 15-2CT | 240V | |

| 388332 | Chromalox SRM/E 20-1C | 20 |

120V |

| 388340 | Chromalox SRM/E 20-1CT | 120V | |

| 388367 | Chromalox SRM/E-20-2C | 240V | |

| 388375 | Chromalox SRM/E 20-2CT | 240V |

Output Wattage at Alternate Voltages (W/Ft.)

| Chromalox Part Number | 208V | % Change In Output | 220V | % Change In Output | 277V | % Change In Output |

| Chromalox SRM/E 5 | 3.85 | -23 | 4.25 | -15 | 6.45 | +23 |

| Chromalox SRM/E 8 | 6.4 | -20 | 6.88 | -14 | 10.24 | +22 |

| Chromalox SRM/E 10 | 8.3 | -17 | 8.80 | -12 | 12.50 | +20 |

| Chromalox SRM/E 15 | 12.75 | -15 | 13.50 | -10 | 18.45 | +19 |

| Chromalox SRM/E 20 | 17.6 | -12 | 18.40 | -8 | 24.40 | +19 |

Chromalox Frost Protection Cable

Construction

- A Twin 16 AWG Copper Buss Wires are able to provide reliable electrical current capability.

- B Semiconductive Polymer Core Matrix is the self regulating component of the cable and it’s electrical resistance varies with temperature.

- C Fluoropolymer Jacket is flame retardant and electrically insulates the matrix and buss wires and provides corrosion resistance.

- D Tinned Copper Braid that provides additional mechanical protection in any environment, and a positive ground path.

- E High Temperature Fluoropolymer Overjacket (optional) is a corrosion resistant, flame retardant overjacket is highly effective in many environments.

frost protection CABLE – HAZARDOUS AREA CERTIFICATIONS

Factory Mutual (FM) Approved, UL Listed, and CSA certified for ordinary areas. ATEX, IECEx, FM, and CSA Approved for hazardous (classified) areas when used with U Series, HL, DL and EL accessories.

Hazardous Area Heating Cables

CSA and FM Approved

- Class I, Div. 1* & 2 Groups A*, B, C, D (gases, vapours)

- Class II, Div. 1*& 2 Groups E*, F, G (combustible dust)

- Class III, Div. 2 (easily ignitable fibres and fillings)

- 5 and 8 Watt Rated T3 Temperature Class

- 10, 15, and 20 Watt Rated T2D Temperature Class

CSA Only

- -CT overjacket only

ATEX Approved

- CE 0359 IIG Ex e IIC T* Gb Ta -60˚C to 195˚C

IECEx Approved

- ITS 07.0018X Ex e IIC T3 Gb Ta -60˚C to 195˚C

Note: Cable Surface Temperature shall not exceed 190°C in Class II, Div. 2, Group F; 165°C in Class II, Div. 2 Group G.

➡ Chris Myers, Product Manager at Chromalox, explains about their heat trace cables and product offering including self regulating trace heating cable.

Industrial Electrical Heating Specialists

We can specify and supply from stock an extensive range of Electrical Heating Equipment for industrial and process heating applications -this includes temperature maintenance and frost protection (Winterisation) products for pipework, valves, IBC’s, drums, hoses, tanks and vessels. We produce custom silicone heaters for rapid and high temperature heat-up of complex shapes and surfaces – from concept, design to the delivery of standard or bespoke heaters on the shortest lead times. From the largest UK heat tracing cable stocks we deliver Electric Trace Heating Systems for pipework frost protection, ramp heating, roof/gutter snow melting and de-icing – enquire about our in-house design service.