Self Regulating Trace Heating | Eltherm ELSR-M Trace Heating Cable (Up to 65 Degrees Celsius)

Thorne & Derrick | Distributed from Stock | UK & Export Sales | Customer Service Excellence

Self Regulating Trace Heating

Trace Heating Cable | Eltherm ELSR-M

Eltherm ELSR-M is a versatile self-regulating trace heating cable that provides process temperature maintenance and frost protection to pipework, instrument lines, tanks and drums up to 65° Celsius.

The self-regulating trace heating technology allows the heating cable to increase or decrease its heat output based on the ambient temperature, providing energy-efficient operation and preventing overheating. ELSR-M is suitable for use in various industrial applications where maintaining consistent temperatures is critical for process integrity and safety including:

- Heat tracing on pipes, pumps and valves

- Food processing industry

- Automotive

- Heating of tube bundle cables for water analysis

- Heat tracing on vessels

Our Team of Trained Sales Engineers are available to advise and support your trace heating enquiries – this includes design and supply of complex multi-kilometre, major-project systems to custom heat trace cable kits for the protection of winterisation against plant and factory facilities.

Eltherm ELSR-M Trace HEAting CABLE – SPECIFICATION

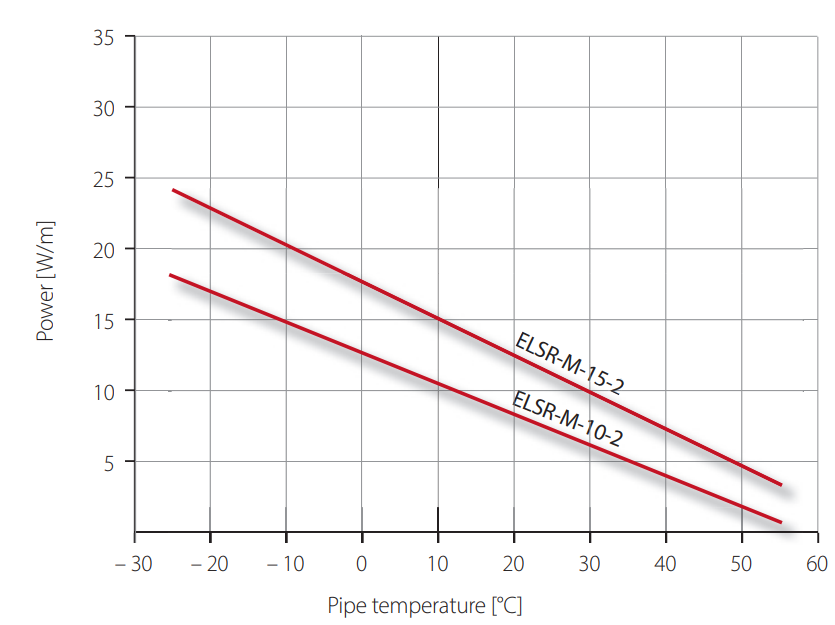

Eltherm ELSR-M self-regulating trace heating wattages per metre at 10°C – 10 and 15 watts.

- Nominal Supply Voltage : 230v

- Maximum Exposure Temperature : Power off 65°C, power on 65°C

- Minimum Installation Temperature : -45° Celsius

- Minimum Heater Cable Bend Radius : 25mm

- Heater Cable Outer Jacket: TPE-O

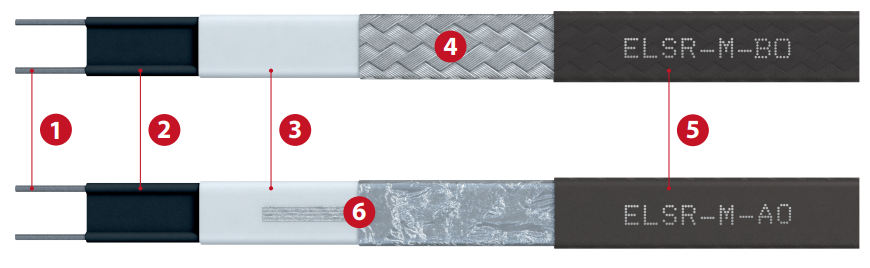

- Bus Wire: Nickel plated copper

- Bus wire – nickel plated copper, 0.62 mm²

- Self-regulating heating element

- Insulation

- Protective braid – (Cu, tin plated)

- Outer jacket – TPE-O

- Protective conductor connection – see 4 or Cu, tin plated with aluminium foil

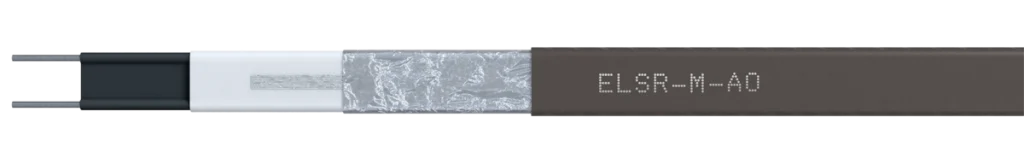

Eltherm ELSR-M self-regulating heating cables are available in two cable designs. The BO version of the ELSR-M heating cable has a protective tin-plated copper braid for all low – temperature and medium – temperature applications.

- BO: Protective braid and a thermoplastic outer jacket

- AO: Aluminium foil and a thermoplastic outer jacket

Eltherm ELSR- M BENEFITS

- Four nominal outputs

- UV-resistant

- Moisture proof

- Highly durable

- Efficient heat distribution

- Junction box for pipe mounting

Eltherm ELSR- M heating cables provide temperature maintenance and frost protection to pipework and mechanical services in all industries – typical applications include heating process pipework, instrument lines and storage tanks to maintain viscosity or prevent frost damage as an integral work-task of plant Winterisation.

Eltherm ELSR-M cables utilise cold-applied installation components to complete the trace heating system – no requirement for “hot-working” permit applications in potentially explosive atmospheres, including Zone 1 and Zone 2 hazardous areas.

Trace Heating Cable Selection Table – Eltherm ELSR-M

Contact T&D for technical guidance, heat loss calculations for pipework systems and optimum specification of the correct trace heating cable for your application.

| Eltherm ELSR-M Heater Cable | Nominal Output | Cable Dimensions (mm) | Cable Weight Approx (g/m) |

| ELSR-M-10-2-AO | 10 w/m at 10ºC | 8.0 x 5.5 | 53 |

| ELSR-M-10-2-BO | 10 w/m at 10ºC | 8.5 x 5.8 | 62 |

| ELSR-M-15-2-AO | 15 w/m at 10ºC | 8.0 x 5.5 | 53 |

| ELSR-M-15-2-BO | 15 w/m at 10ºC | 8.5 x 5.8 | 62 |

Eltherm ELSR-M heating cable power output on insulated metallic pipes in accordance with EN 62395-1

ELSR-M Heating circuit length

| Switch on temperature [°C] | Nominal fuse rating [A] | Heating circuit length*1 [m] | |

| ELSR-M-10-2 | ELSR-M-15-2 | ||

| 10 | 10 | 126.0 | 98.0 |

| 16 | 126.0 | 105.0 | |

| 20 | 126.0 | 105.0 | |

| 0 | 10 | 115.0 | 83.0 |

| 16 | 115.0 | 97.0 | |

| 20 | 115.0 | 97.0 | |

| -10 | 10 | 90.0 | 72.0 |

| 16 | 144.0 | 91.0 | |

| 20 | 149.0 | 91.0 | |

| – 20 | 10 | 78.0 | 64.0 |

| 16 | 125.0 | 85.0 | |

| 20 | 139.0 | 85.0 | |

| -40 | 10 | 62.0 | 52.0 |

| 16 | 99.0 | 77.0 | |

| 20 | 124.0 | 77.0 | |

*1 Heating circuit lengths on the following conditions:

- 230 V nominal voltage

- Delayed action circuit breakers (C-characteristic) with 80 % max. load

- Maximum 10 % line voltage drop on heating cable bus wire

- Power connection to one heater end

- In certain installation situations, the heating circuit length may vary. Please contact T&D

Eltherm video providing a step-by-step termination of ELSR-N heater cable using a EL-ECN termination kit.

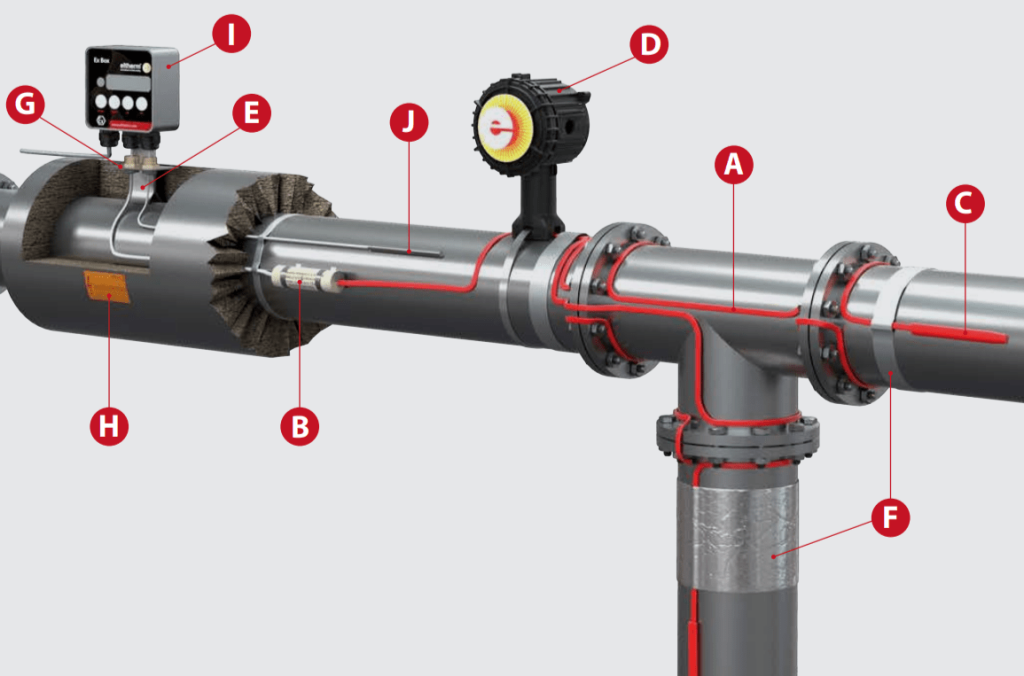

Self-Regulating Trace Heating System

A Trace Heater

B Power Connection Kit

C End Termination Kit

D Junction Box

E Pipe Mounting Bracket

F Fasteners and Self-adhesive Tapes, Foils

G Insulation Bushing

H Warning Sign

I Temperature Controller

J Temperature Sensor

Bespoke Heated Hose Designs | 40+ Years Experience from Process Heating Specialists | CONTACT US