Ex Lighting I Understanding Nameplates Guide By Raytec

Published 07 Oct 2021

Understanding Nameplates for Ex Lighting

Hazardous Area Lighting

Nameplates for Ex Lighting

Namplates for hazardous area lighting provide valuable information about the ex luminaire. It allows you to identify the manufacturer, the areas in which it’s safe to be used, as well as information about the luminaire’s specification, such as input voltage, ingress protection rating and much more.

For installers and end-users, this information is critical to ensuring the luminaire is installed correctly and safety on-site is maintained.

For a manufacturer, such as Raytec, developing products specifically for hazardous locations, nameplates are a necessity to showcase the latest and appropriate certification standards. It is important that manufacturers keep their nameplates up to date with the correct information.

If not, unclear markings can lead to incorrect equipment being purchased and installed on-site. This can be detrimental to the safety of the individuals located there.

Understanding Nameplates For Ex lighting

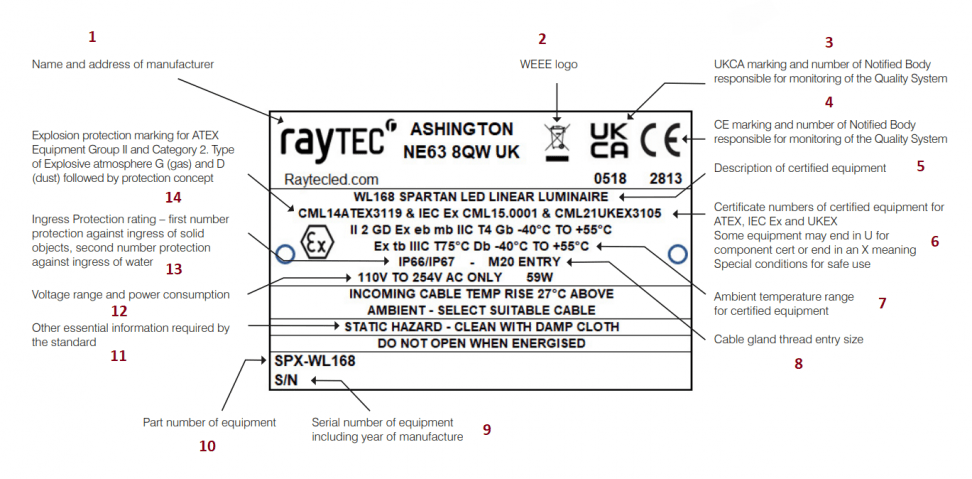

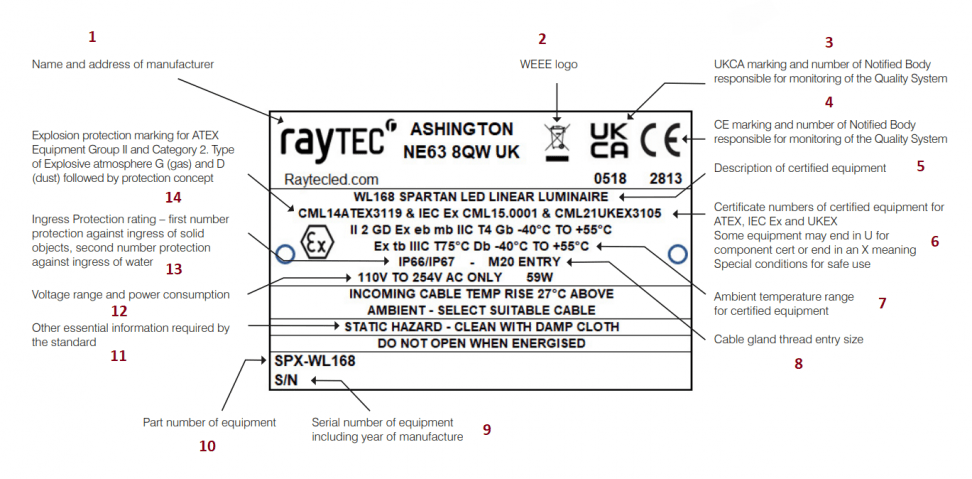

To understand the different information a nameplate tells us, we’ll look at an example of the nameplate that would be fitted to Raytec’s SPARTAN WL168 Linear luminaire. The look and layout of a nameplate will vary between the manufacturer, however, this is a typical example of the markings you should expect to see from on a luminaire that has been certified for use in a hazardous area.

1 – The name and address of the manufacturer, as well as the web address of the manufacturers’ website.

2 – WEEE logo – this symbol indicates that the product should not be discarded as unsorted waste but must be sent to separate collection facilities for recovery and recycling. The WEEE marking must appear on any electrical and electronic equipment placed on the EU market.

3, 4 & 14 – Certification symbols – showing that this product is certified to ATEX, IEC EX and UKCA standards. Raytec use a tri-rated nameplate on luminaires which means there will be three certificate numbers included on a product label – ATEX, IEC EX and UKCA. Showcasing each of these certification markings on each Raytec nameplate means the same luminaire can be used worldwide.

5 – Description of certified equipment.

6 – Certificate numbers of certified equipment for ATEX, IEC Ex and UKEX (all certificates should be accessible via the manufacturers website). Look out here an ‘X’ at the end of the certificate. If this is it means the products have a condition for safe use which the end-user must follow.

7 – Luminaire operating temperature – showing the minimum and maximum temperature.

8 – Cable gland thread entry size.

9 – Serial number of the equipment.

10 – Equipment part number.

11 – Other essential information required by the standard, such as cleaning procedure.

12– Voltage range and consumption.

13 – Ingress protection rating.

Raytec Spartan Linear SPX-WL168 Zone 1 Hazardous Area 6,130 Lumens

Ex Lighting Nameplate Material

The nameplate is arguably the most critical component of a hazardous area product. It is important the information and markings on the nameplate remain legible for the lifetime of the product. The manufacturer should therefore give careful consideration to the materials from which the nameplate is designed. Let’s touch on this briefly.

Whilst all manufacturers must keep their nameplates up to date, many produce them using materials that are unable to withstand the harsh environments to which they are exposed. Most commonly, nameplates found on Ex lighting consist of a printed, self-adhesive, polyester label.

While these self-adhesive nameplates are adequate for many indoor applications, Ex environments are often harsh and demanding, with exposure to extremes in temperatures, humidity, and corrosive atmospheres.

These conditions could lead to the information on a label being weathered or erased, to the point where it cannot be read. Or worse, it could even cause the label itself to detach from the product, leaving the luminaire unmarked and untraceable.

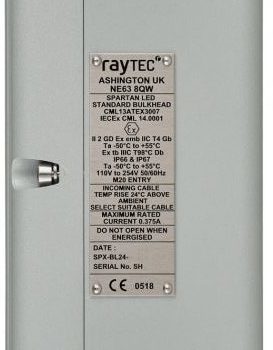

A more robust method is to use metal nameplates where the information is engraved, ensuring it remains legible throughout the Ex lighting’s lifetime. At Raytec, we utilise this method, where all our SPARTAN Ex lighting are fitted with a laser-engraved, stainless steel certification nameplate which is riveted to the luminaire so it cannot become detached. This allows our nameplates to withstand the harshest of environments.

Raytec Emergency Hazardous Area Lighting

💡 Did you Know? Thorne & Derrick using latest software provide a FREE LIGHTING DESIGN SERVICE for the specification and supply of ATEX & IECEx Certified light fittings to provide safe and reliable lighting in explosive atmospheres and hazardous area locations.

Industry leading manufacturers of Lighting Products for hazardous areas | Raytec

SPARTAN is a full range of Ex LED luminaires and lighting approved for all ATEX and IEC Ex Zone 1 and Zone 2 hazardous area environments, including UL /CSA C1D2 installations. The hazardous area lighting products are designed for the most extreme environments – Flood, Linear, Bulkhead, Bay and Crane luminaires with emergency and industrial lighting versions are also available from Thorne & Derrick International.

➡ Further Reading: Raytec SPARTAN Linear Generation II | The Evolution & Spartan Linear Generation II | Raytec Case Study

Specialists to the Process & Hazardous Area Industries

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

leaders in ATEX Innovation To The Hazardous Area Industries

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control