Hazardous Area Level Sensors & Float Switches – Deeter Gain CSA Approval

Published 17 Jan 2017

Explosion Proof Level Sensors & Float Switches

- By Chris Dodds : estimated reading time 5 minutes

Hazardous Area Level Sensors

In addition to ATEX and IECEx Certification for their range of hazardous area level sensors and level switches, Deeter are now certified to CSA standards for Explosion Proof Accreditation.

CSA is the Canadian Standards Association which provides product testing and certification for a wide variety of electrical and mechanical products including level sensors for hazardous areas and locations.

Contact T&D for monitoring and level sensing of liquids – products with ATEX and IECEx certification are available including hazardous area float switches, liquid level sensors and load cells.

Learn more about Deeter.

Hazardous Area Classifications – CSA

hazardous areA locations

in North America

In North America, hazardous area workplaces and locations have traditionally been defined by a combination of Classes and Divisions:

hazardous area Classes

- Class I – a location or area made hazardous by the presence of flammable gases or vapors that may be present in the air in quantities sufficient to produce an explosive or ignitable mixture

- Class II – a location or area made hazardous by the presence of combustible or electrically conductive dust

- Class III – a location or area made hazardous by the presence of easily ignitable fibers or flyings in the air, but not likely to be in suspension in quantities sufficient to produce ignitable mixtures

Hazardous Area Divisions

- Division 1 – a location or area where a classified hazard exists or is likely to exist under normal conditions

- Division 2 – a location or area where a classified hazard does not normally exist but is possible to appear under abnormal conditions

North American transition to the

hazardous area zone system

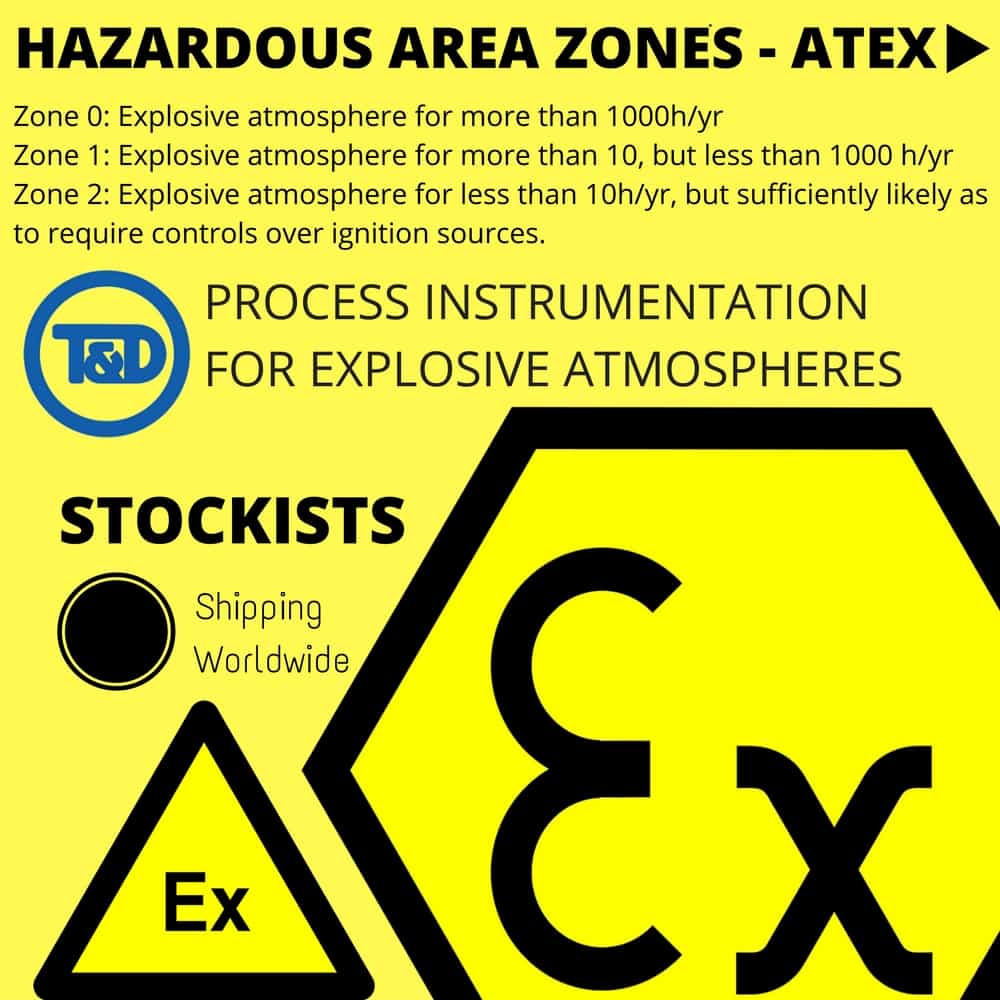

The U.S. and Canada have recently revised installation codes to recognize an international 3-Zone area classification system for equipment used in hazardous locations.

- Zone 0 – an area in which an explosive gas atmosphere is continuously present for a long period of time

- Zone 1 – an area in which an explosive atmosphere is likely to occur in normal operation

- Zone 2 – an area in which an explosive gas atmosphere does not normally exist

In Canada, all new installations must use the 3-Zone system – existing installations may continue to use the 2-Division system or opt to re-classify using the 3-Zone system.

In the U.S., all installations (both new and existing) can either continue using the 2-Division system or re-classify their product using the 3-Zone system.

Should you require any assistance selecting hazardous area level sensors for international classifications including ATEX, IECEx and CSA please do not hesitate to contact us.

Contact T&D to discuss your Hazardous Area Process Instrumentation requirements.

Hazardous Area Level Sensors

Deeter are a leading designer and manufacturer of electronic sensors and control systems for level measurement requirements and produce a range of explosion proof level sensors and float switches for use in hazardous area applications.

CSA approval, along with Deeter’s ATEX & IECEx certifications allows the Deeter LVCS FP level sensor and FS FP hazardous area float switch to be suitable for use in hazardous area applications in most regions worldwide.

Deeter ATEX & IECEX Certified Explosion Proof Range

Deeter LVCS-FP is a flameproof continuous liquid level sensor suitable for hazardous area applications and offers accurate level measurement using a magnetic float with a reed switch or Hall Effect sensor stem.

Deeter LVCS-FP level sensor is available in standard length sensor stems from 250mm to 2m and can be custom made to suit up to 4 metres.

Liquid Level & Float Sensors

The Deeter F/S- FP is a flameproof float switch suitable for hazardous area applications and offers flexible switching options using a magnetic float with a reed switch or Hall Effect sensor stem.

The F/S FP float switches are available in a number of standard length sensor stems – additionally up to 7 switch points can be fitted on one stem with a mix of normally open / normally closed switches to suit the application.

Explosion & Flameproof Liquid Level & Float Sensors

Both the LVCS FP level sensor and F/S FP float switch are suitable for hazardous area Zone 0, 1 and 2 applications and can be custom made to suit client requirements and still meet ATEX, IECEx and CSA directives.

Further Reading

Radar Level Measurement – How Does It Work?

Guided Wave Radar Level Sensor – How Does it Work?

Process Instrumentation Equipment

for Hazardous Areas & Explosive Atmospheres

Thorne & Derrick International, based in the UK, distribute Explosion Proof & Hazardous Area Process Instrumentation Equipment (ATEX & IECEx Certified): this includes industrial measurement probes, humidity sensors, data loggers, handheld instruments and transmitters for temperature measurement and monitoring of relative humidity. Additionally, hazardous area instrumentation is also available for monitoring carbon dioxide, differential and process pressure, flow, dew point, water activity and analog signals.

- ASCO – Solenoid Valves for Air, Water, Vacuum, Steam, Oil, Acids and Alkali

- Ashcroft – Pressure Gauges

- Deeter Electronics Ltd – Level Sensors & Float Switches

- Fisher – Control Valves (Rotary, Sanitary & Sliding Stem)

- IFM Electronic – Sensors (Temperature, Flow, Pressure & Level Measurement)

- Katronic – Ultrasonic Flowmeters & Flow Measurement

- KROHNE – Hazardous Area Process Instrumentation, Meters & Measurement

- Micronics – Flow Meters (Ultrasonic Clamp-On Fixed & Portable Meters)

- Rotronic – Sensors, Probes, Indicators, Transmitters & Measurement Instruments

- SICK – Temperature, Level, Pressure & Flow Sensors

- Sika – Temperature Calibrators, Flow Meters & Magnetic Flow Sensors (Magmeters)

- VEGA – Level, Point Level & Pressure Measurement Sensors, Instruments & Transmitters

- Hazardous Area Lighting | Junction Boxes & Enclosures | Plugs | Electrical Panels

- Detection Systems for Hazardous Areas | Gas | Heat | Flame | Fire

Invitation – network, engage, promote

Thorne & Derrick are inviting you to join LinkedIn’s fastest growing Discussion Group – Process & Hazardous Area Industries : Heat Tracing, Gas Detection, Fluid Control & Flow Measurement. News, projects, videos, promotions, whitepapers, jobs, webinars, press plus much more.

ABOUT US

See How T&D Support The Food & Beverage Industry

Thorne & Derrick International are your single-source supplier of Electrical, Mechanical, Process & Instrumentation Equipment. T&D provide an outstanding service to UK and international customers – we are highly customer responsive and absolutely committed to providing a world-class service.

T&D supply utilities, power, renewable energy, construction, rail, manufacturing, food/beverage, mining, oil, gas and petrochemical industries – distributing 100,000+ products from 100+ manufacturers from multi-million pound stocks. Since 1985 we have established a solid reputation based on service, integrity and trust.

Further Reading

-

Hazardous Area Liquid Level Sensor (ATEX IECEx) – Deeter LVCS-FP Sensor – IECEX

Size: 261.28 KB

Hazardous Area Liquid Level Sensor (ATEX IECEx) – Deeter LVCS-FP Sensor – IECEX

Size: 261.28 KB

-

Hazardous Area Float Switch (ATEX IECEX) – Deeter VFS-FP Switch – IECEX

Size: 263.58 KB

Hazardous Area Float Switch (ATEX IECEX) – Deeter VFS-FP Switch – IECEX

Size: 263.58 KB