Pipe Heat Tracing Cables for Solar (CSP) | Temperature Maintenance & Freeze Prevention In Industrial & Hazardous Areas

Published 26 Mar 2021

Pipe Heat Tracing Cables for Solar (CSP)

Heat Tracing Cables By Eltherm

Frost Protection For Industrial & Hazardous Areas

In the second of this blog series by Eltherm they will discuss the best electrical trace heating system that will ensure temperature maintenance and freeze prevention in the Moroccan desert. Pipe heat tracing cables for solar (CSP) as deserts reach cold temperatures at night.

The average annual solar radiation in the Moroccan desert lies at 2.635 kWh/m², the highest in the world. Not surprisingly, one of the world‘s largest concentrated solar power plant is NOOR III, located between the Atlas Mountains and the Sahara in Morocco, covering 10.800 m². It has a capacity of 150 MW and 7.5 hours of full energy production. By the way: Noor means “light“ in Arabian.

The 240 m NOOR III tower stands in a field of biaxial heliostats. Sunrays are reflected from the heliostats to the receiver at the top of the tower. In order to transport, store and convert this solar energy to power, molten salts must be heated to 550 °C and kept at temperature to prevent them from solidifying and thus clogging. This occurs at +260 °C.

This is why not just the molten salts, but also carrier and synthetic oils must be held at 15 °C, water above freezing and condensation avoided, too. This is where the electrical heat tracing system performs its major task. Thus, electrical heat tracing fulfils its main task: to maintain temperatures along the entire process. This applies to a wide range of facilities and installations for production, transport and storage, on pipelines, tanks and silos.

Eltherm – Heat Tracing Solutions

Heat Tracing Cables for for Solar (CSP)

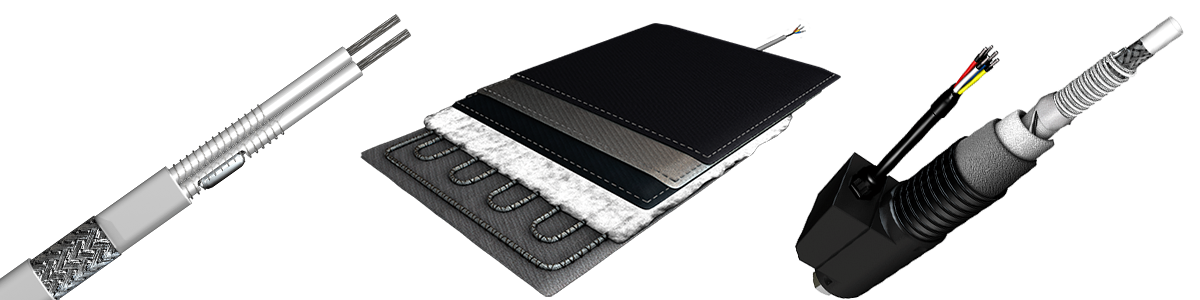

From engineering to commissioning:

- 42 km ELK-MI AY825 mineral-insulated trace heaters with clean laser seal technology for temperatures up to 550° C

- 760 specially developed resistance trace heaters

- 110 km heating lines

- 770 heating circuits

- 28 control stations

Eltherm Trace Heating Advantages:

- Mineral-insulated trace heaters ELK-MI

- Constant reliable temperature maintenance

- Central control for safe operation

- Energy efficiency

- On-site support

Schematic view of electrical heat tracing on pipelines, valves and tanks

Thorne & Derrick specialise in providing specialist heating for industrial and hazardous areas including Eltherm’s heat tracing cables and heated hoses.

ELTHERM INDUSTRIAL & HAZARDOUS AREA HEATING

Eltherm heating products provide freeze protection, temperature maintenance and temperature control ranges of up to 1000°C and are used in many industries and applications from oil and gas to utilities and power generation. Eltherm products are manufactured to the highest hazardous area specifications including ATEX and IECEx for heating pipes, hoses, drums, vessels and IBC’s.

Eltherm self regulating heat trace cable provides frost protection and maintains product viscosity in pipes, tanks, drums and vessels

Electrical Heating Specialists

Thorne & Derrick International, based in the UK, can specify and supply from stock an extensive range of Electrical Heating Equipment for industrial and process heating applications – this includes temperature maintenance and frost protection (Winterisation) products for pipework, valves, IBC’s, drums, hoses, tanks and vessels. We produce custom silicone heaters for rapid and high temperature heat-up of complex shapes and surfaces – from concept, design to the delivery of standard or bespoke heaters on the shortest lead times. From the largest UK heat tracing cable stocks we deliver Electric Trace Heating Systems for pipework frost protection, ramp heating, roof/gutter snow melting and de-icing – enquire about our in-house design service.

Further Reading : Winterisation | Electrical Heating Solutions to Overcome Cold Climate Challenges

EXPERTS IN WINTERISATION SOLUTIONS FOR INDUSTRIAL & HAZARDOUS AREA ENVIRONMENTS

Thorne & Derrick hold the largest UK stocks of frost protection & winterisation equipment to help keep your plant and personnel operational during the winter months.

Thorne & Derrick understand that prolonged periods of low ambient temperatures can bring operations to a standstill costing thousands of pounds in lost downtime.

Experts in heating solutions for use in industrial & explosive atmospheres, Thorne & Derrick have the knowledge & expertise to help clients prevent unnecessary down time this winter.

We can provide overnight delivery of Trace Heating Cables at the most competitive prices to guarantee frost protection of your pipelines and mechanical services.| Ask About Our Heat Trace Design Service.

💡 Contact us today and our skilled and friendly team can provide technical support as well as reliable, fit for purpose and compliant solutions to suit your exact requirements.

Trace Heating | Process Heating | Heating Jackets | Drum & IBC Heaters | Heated Hoses |Silicone Heating Mats

➡See our Winterisation blog TOP PICKS, including our most read articles about Trace Heating and the requirement for electrical heating products and systems to combat and mitigate Winter weather effects.

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery