Self Regulating Heat Tracing | Eltherm ELSR-H ATEX Heat Tracing Cable (Up to 210 Degrees Celsius)

Thorne & Derrick | Distributed from Stock | UK & Export Sales | Customer Service Excellence | ATEX Compliant Solutions

Self Regulating heat tracing

ATEX Heat Tracing Cable | Eltherm ELSR-H

Eltherm ELSR-H is a self-regulating heat tracing cables provide process temperature maintenance and frost protection to pipework, instrument lines, tanks and drums up to 210° Celsius – with IECEx and ATEX Certification Eltherm ELSR-H heat tracing cables are suitable for Zone 1 and Zone 2 hazardous areas.

The ELSR-H heating cable is designed to provide safe and reliable heat tracing for pipes and vessels in hazardous areas, helping to prevent freezing and maintain the temperature of critical processes. It is available in a range of power outputs and can be easily installed using a variety of fixing methods. Suitable for a range of different applications including:

- Valves, pumps

- Silos, vessels, tanks

- Chemistry and Petrochemistry

- Oil and Gas Industry

- Power plants

- Water and sanitation utilities

Our Team of Trained Sales Engineers are available to advise and support your ATEX heat tracing enquiries – this includes design and supply of complex multi-kilometre, major-project systems to custom heat trace cable kits for the protection of winterisation against plant and factory facilities.

Eltherm ELSR-H heat tracing CABLE – SPECIFICATION

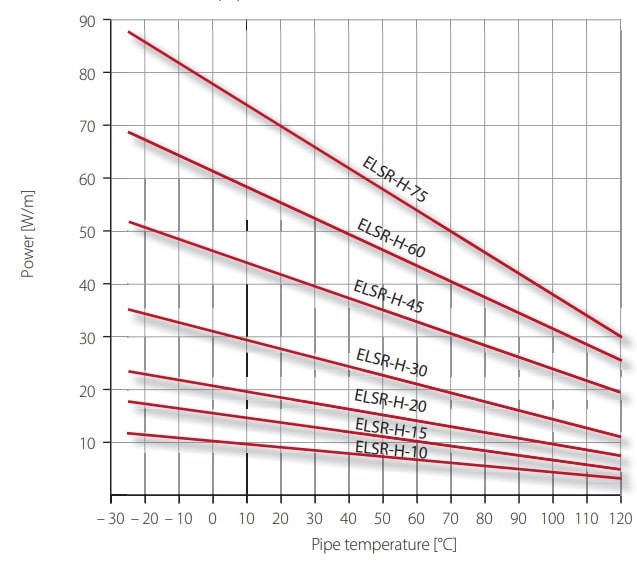

Eltherm ELSR-H Heater Cable wattages per metre at 10°C – 10, 15, 20, 30, 45, 60 and 75 watts.

- Nominal Supply Voltage : 230v (further power inputs on request)

- Maximum Exposure Temperature : Power off 210°C, power on 120°C

- Minimum Installation Temperature : -60° Celsius

- Minimum Heater Cable Bend Radius : 25mm

- Heater Cable Outer Jacket: Fluoropolymer

- Bus Wire: Nickel plated copper, 1.23 mm²

- Use in hazardous areas (is permitted up to 180 °C) Please contact T&D for design and specification advice

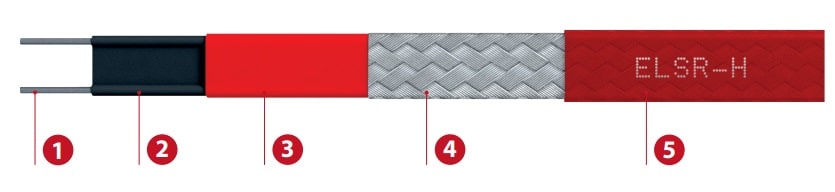

- Bus wire – nickel plated copper, 1.23 mm²

- Self-regulating heating element

- Insulation – fluoropolymer

- Protective braid – (Cu, tin plated)

- Outer jacket – fluoropolymer

Eltherm ELSR-H self-regulating heater cables has a BOT cable design which has a high chemical resistance and is able to withstand aggressive chemicals, oil and fuel for improved service life due to the protective braid and fluoropolymer outer jacket.

Hazardous Area Classifications

![]()

Heat Tracing Classification:

- II 2G Ex 60079-30-1 IIC Gb

- II 2D Ex 60079-30-1 IIIC Db

![]() System Classification:

System Classification:

- II 2G Ex 60079-30-1 eb IIC T3 Gb

- II 2D Ex 60079-30-1 tb IIIC T200°C Db

![]() Hazardous Area Certification:

Hazardous Area Certification:

- IECEx EPS 12.0004 U

- IECEx EPS 19.0006 X

- EPS 12 ATEX 1 429 U

- EPS 19 ATEX 1013 X

- CML 21 UKEX 3806 U

- CML 21 UKEX 3905 X

Temperature Class: T3

Eltherm ELSR-H Benefits

- Seven nominal outputs

- Moisture proof

- Resistant to chemicals

- Use in hazardous areas (is permitted up to 180 °C)

The Eltherm ELSR-H high temperature trace heating range is designed for temperature maintenance in industrial processes and applications in hazardous areas. The trace heaters’ high chemical resistance allows them to be installed in environments with exposure to aggressive influences.

heat tracing Cable Selection Table – Eltherm ELSR-H

Contact T&D for technical guidance, heat loss calculations for pipework systems and optimum specification of the correct trace heater cable for your application.

| Eltherm ELSR-H Heater Cable | Nominal Output | Cable Dimensions (mm) | Cable Weight Approx (g/m) |

| ELSR-H-10-2-BOT | 10 w/m at 10ºC | 12.4 x 5.0 | 120 |

| ELSR-H-15-2-BOT | 15 w/m at 10ºC | 12.4 x 5.0 | 120 |

| ELSR-H-20-2-BOT | 20 w/m at 10ºC | 12.4 x 5.0 | 120 |

| ELSR-H-30-2-BOT | 30 w/m at 10ºC | 12.4 x 5.0 | 120 |

| ELSR-H-45-2-BOT | 45 w/m at 10ºC | 12.4 x 5.0 | 120 |

| ELSR-H-60-2-BOT | 60 w/m at 10ºC | 12.4 x 5.0 | 120 |

| ELSR-H-75-2-BOT | 75 w/m at 10ºC | 12.4 x 5.0 | 120 |

Eltherm ELSR-H heating cable power output on insulated metallic pipes in accordance with EN 62395-1

ELSR-H Heating circuit length

| Switch on temperature [°C] | Nominal fuse rating [A] |

Heating circuit length*1 [m] | ||||||

| ELSR-H10-2-BOT | ELSR-H15-2-BOT | ELSR-H20-2-BOT | ELSR-H30-2-BOT | ELSR-H45-2-BOT | ELSR-H60-2-BOT | ELSR-H75-BOT | ||

| 10 | 16 | 193.0 | 158.0 | 122.0 | 82.0 | 55.0 | 41.0 | 33.0 |

| 20 | 193.0 | 158.0 | 136.0 | 102.0 | 68.0 | 51.0 | 41.0 | |

| 25 | 193.0 | 158.0 | 136.0 | 111.0 | 85.0 | 64.0 | 51.0 | |

| 32 | 193.0 | 158.0 | 136.0 | 111.0 | 91.0 | 79.0 | 66.0 | |

| 0 | 16 | 189.0 | 153.0 | 116.0 | 77.0 | 52.0 | 39.0 | 30.0 |

| 20 | 189.0 | 153.0 | 132.0 | 97.0 | 65.0 | 49.0 | 37.0 | |

| 25 | 189.0 | 153.0 | 132.0 | 108.0 | 81.0 | 61.0 | 47.0 | |

| 32 | 189.0 | 153.0 | 132.0 | 108.0 | 88.0 | 77.0 | 60.0 | |

| -10 | 16 | 184.0 | 146.0 | 110.0 | 73.0 | 50.0 | 37.0 | 28.0 |

| 20 | 184.0 | 148.0 | 129.0 | 92.0 | 62.0 | 46.0 | 35.0 | |

| 25 | 184.0 | 148.0 | 129.0 | 105.0 | 77.0 | 58.0 | 44.0 | |

| 32 | 184.0 | 148.0 | 129.0 | 105.0 | 86.0 | 70.0 | 57.0 | |

| -20 | 16 | 180.0 | 139.0 | 104.0 | 70.0 | 47.0 | 36.0 | 26.0 |

| 20 | 180.0 | 145.0 | 125.0 | 87.0 | 59.0 | 44.0 | 33.0 | |

| 25 | 180.0 | 145.0 | 125.0 | 103.0 | 74.0 | 56.0 | 41.0 | |

| 32 | 180.0 | 145.0 | 125.0 | 103.0 | 84.0 | 67.0 | 53.0 | |

| -40 | 16 | 173.0 | 126.0 | 95.0 | 64.0 | 43.0 | 33.0 | 23.0 |

| 20 | 173.0 | 138.0 | 119.0 | 80.0 | 54.0 | 41.0 | 29.0 | |

| 25 | 173.0 | 138.0 | 120.0 | 98.0 | 68.0 | 51.0 | 36.0 | |

| 32 | 173.0 | 138.0 | 120.0 | 98.0 | 81.0 | 61.0 | 46.0 | |

*1 Heating circuit lengths on the following conditions:

- 230 V nominal voltage

- Delayed action circuit breakers (C-characteristic) with 80 % max. load

- Maximum 10 % line voltage drop on heating cable bus wire

- Power connection to one heater end

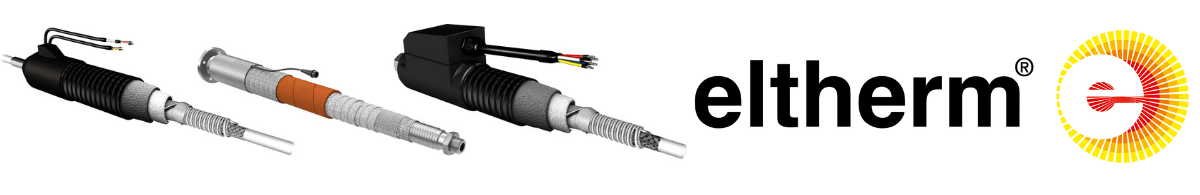

Eltherm video providing a step-by-step connection of ELSR-H hazardous area heater cable using a Ex-Con cable joint.

Self-Regulating heat tracing System

A Trace Heater

B Power Connection Kit

C End Termination Kit

D Junction Box

E Pipe Mounting Bracket

F Fasteners and Self-adhesive Tapes, Foils

G Insulation Bushing

H Warning Sign

I Temperature Controller

J Temperature Sensor

Self-Regulating Heat Tracing System

Bespoke Heated Hose Designs | 40+ Years Experience from Process Heating Specialists | CONTACT US