Self Regulating Heat Tracing | Eltherm ELSR-LS ATEX Heat Tracing Cable (Up to 80 Degrees Celsius)

Thorne & Derrick | Distributed from Stock | UK & Export Sales | Customer Service Excellence | ATEX Compliant Solutions

Self Regulating heat tracing

ATEX Heat Tracing Cable | Eltherm ELSR-LS

Eltherm ELSR-LS self-regulating heat tracing cables provide process temperature maintenance and frost protection to pipework, instrument lines, tanks and drums up to 80° Celsius – with IECEx and ATEX Certification Eltherm ELSR-LS heat tracing cables are suitable for Zone 1 and Zone 2 hazardous areas.

The self-regulating feature of this heating cable ensures that it automatically adjusts its power output based on the ambient temperature, providing energy efficiency and preventing overheating. The Eltherm ELSR-LS is easy to install and requires minimal maintenance, making it a cost-effective solution for industrial heating applications such as:

- Chemistry & petrochemistry

- Maritime & offshore

- Food processing Industry

- Water & sanitation utilities

Our Team of Trained Sales Engineers are available to advise and support your ATEX heat tracing enquiries – this includes design and supply of complex multi-kilometre, major-project systems to custom heat trace cable kits for the protection of winterisation against plant and factory facilities.

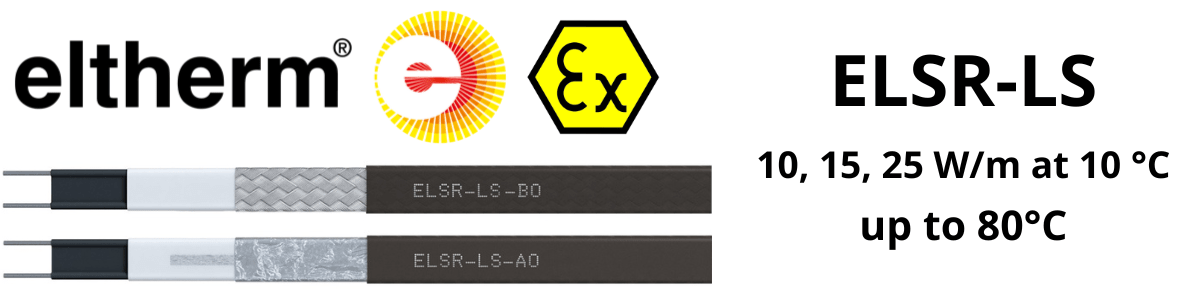

Eltherm ELSR-LS heat tracing CABLE – SPECIFICATION

Eltherm ELSR-LS Heater Cable wattages per metre at 10°C – 10, 15 and 25 watts.

- Nominal Supply Voltage : 230v

- Maximum Exposure Temperature : Power off 80°C, power on 65°C

- Minimum Installation Temperature : -60° Celsius

- Minimum Heater Cable Bend Radius : 25mm

- Heater Cable Outer Jacket: TPE-O

- Bus Wire: 1.23mm² Nickel plated copper

- Bus wire – nickel plated copper, 1.23 mm²

- Self-regulating heating element

- Insulation

- Protective braid – (Cu, tin plated)

- Outer jacket – TPE-O

- Protective conductor connection – see 4 or Cu, tin plated with aluminium foil

Eltherm ELSR-LS self-regulating heating cables are available in two cable designs:

- BO: Protective braid and a thermoplastic outer jacket

- AO: Aluminium foil and a thermoplastic outer jacket

Hazardous Area Classifications

![]() Heat Tracing Classification:

Heat Tracing Classification:

- II 2G Ex 60079-30-1 IIC Gb

- II 2D Ex 60079-30-1 IIIC Db

![]() Cable Classification:

Cable Classification:

- II 2G Ex 60079-30-1 eb IIC T6 Gb

- II 2D Ex 60079-30-1 tb IIIC T85C Db

Hazardous Area Certification: ![]()

- EPS 19 ATEX 1 215 U

- EPS 21 ATEX 1070 X

- CML 21 UKEX 3812 U

- CML 21 UKEX 3814 X

Temperature Class: T6

Eltherm ELSR-N Benefits

- Three nominal outputs

- UV-resistant

- Moisture proof

- Small dimensions

- Efficient heat distribution

Eltherm ELSR-LS cables utilise cold-applied installation components to complete the trace heating system – no requirement for “hot-working” permit applications in potentially explosive atmospheres, including Zone 1 and Zone 2 hazardous areas.

heat tracing Cable Selection Table – Eltherm ELSR-LS

Contact T&D for technical guidance, heat loss calculations for pipework systems and optimum specification of the correct trace heater cable for your application.

| Eltherm ELSR-LS Heater Cable | Nominal Output | Cable Dimensions (mm) | Cable Weight Approx (g/m) |

| ELSR-LS-10-2-AO | 10 w/m at 10ºC | 10.3 x 5.3 | 78 |

| ELSR-LS-10-2-BO | 10 w/m at 10ºC | 11.0 x 5.6 | 98 |

| ELSR-LS-15-2-AO | 15 w/m at 10ºC | 10.3 x 5.3 | 78 |

| ELSR-LS-15-2-BO | 15 w/m at 10ºC | 11.0 x 5.3 | 98 |

| ELSR-LS-25-2-AO | 25 w/m at 10ºC | 10.3 x 5.3 | 78 |

| ELSR-LS-25-2-BO | 25 w/m at 10ºC | 11.0 x 5.6 | 98 |

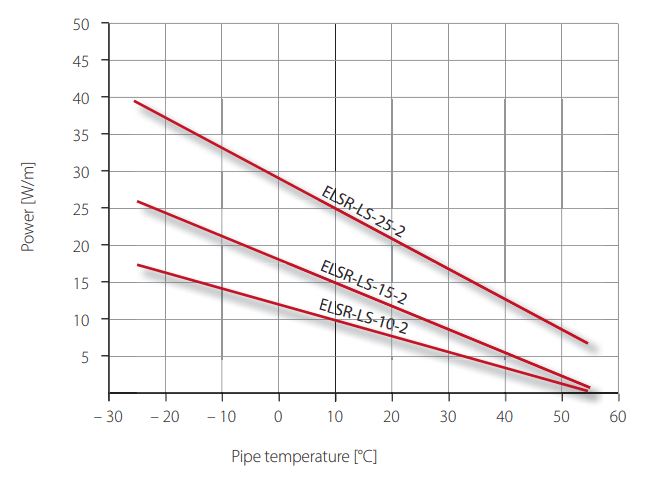

Eltherm ELSR-LS heating cable power output on insulated metallic pipes in accordance with EN 62395-1

ELSR-LS Heating circuit length

| Switch on temperature [°C] | Nominal fuse rating [A] | Heating circuit length*1 [m] | ||

| ELSR-LS-10-2 | ELSR-LS-15-2 | ELSR-LS-25-2 | ||

| 10 | 10 | 152.0 | 103.0 | 64.0 |

| 16 | 196.0 | 160.5 | 103.0 | |

| 20 | 196.0 | 160.5 | 126.0 | |

| 25 | 196.0 | 160.5 | 126.0 | |

| 0 | 10 | 141.0 | 84.0 | 54.0 |

| 16 | 188.5 | 134.0 | 87.0 | |

| 20 | 188.5 | 145.0 | 108.0 | |

| 25 | 188.5 | 145.0 | 116.0 | |

| -10 | 10 | 119.0 | 71.0 | 47.0 |

| 16 | 173.5 | 114.0 | 75.0 | |

| 20 | 173.5 | 133.0 | 94.0 | |

| 25 | 173.5 | 133.0 | 107.5 | |

| – 20 | 10 | 103.0 | 62.0 | 37.5 |

| 16 | 161.0 | 99.0 | 60.0 | |

| 20 | 161.0 | 124.0 | 75.0 | |

| 25 | 161.0 | 124.0 | 94.0 | |

*1 Heating circuit lengths on the following conditions:

- 230 V nominal voltage

- Delayed action circuit breakers (C-characteristic) with 80 % max. load

- Maximum 10 % line voltage drop on heating cable bus wire

- Power connection to one heater end

- In certain installation situations, the heating circuit length may vary. Please contact T&D

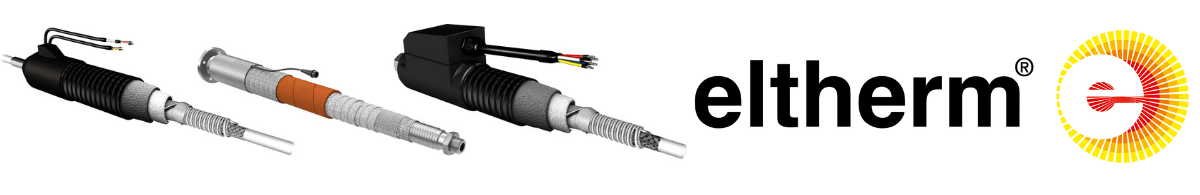

Self-Regulating Trace Heating System

A Trace Heater

B Power Connection Kit

C End Termination Kit

D Junction Box

E Pipe Mounting Bracket

F Fasteners and Self-adhesive Tapes, Foils

G Insulation Bushing

H Warning Sign

I Temperature Controller

J Temperature Sensor

Self-Regulating Trace Heating System

Bespoke Heated Hose Designs | 40+ Years Experience from Process Heating Specialists | CONTACT US