SICK S700 | Extractive Gas Analyser For Hazardous Area Emission Monitoring

Extractive Gas Analysers

SICK S700

Tailor-made gas analysis for process and emission monitoring

The S700 modular system is an extractive gas analyser manufactured by SICK which is very easy to configure and provides a tailor-made application.

The housing of the S700 can be equipped with up to 3 analyser modules for a compact and cost-effective system solution – A total of 6 different analyser modules are available for analysing more than 60 gas components.

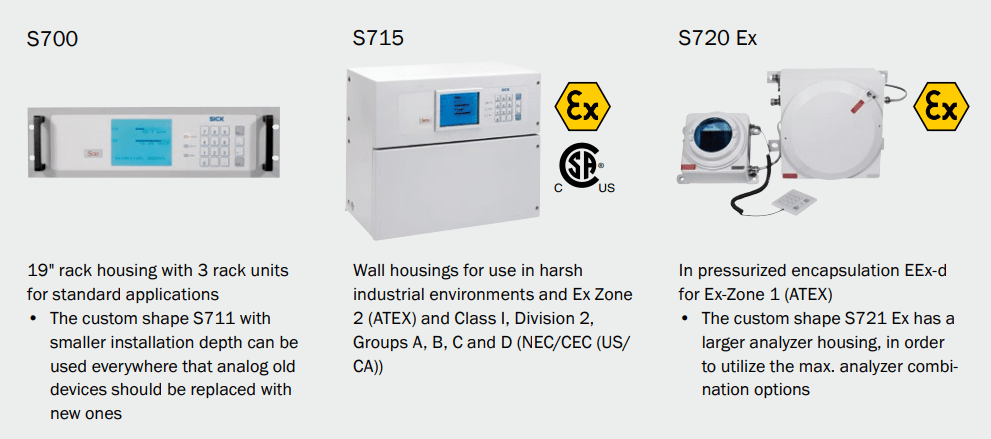

Depending on the measuring task, installation site, and ambient conditions, the following housing types are available:

- S710 19″ rack: Suitable for analyser cabinets and standard applications

- S715 wall-mounting enclosure: For applications in harsh conditions and ATEX certified Zone 2 potentially explosive environments

- S720 flame-proof housing: For Zone 1 explosive environment (ATEX)

Typical Applications for SICK S700

- Emission measurement according to 13th (2001/80/EC), 17th (2000/76/EC), and 27th German Federal Emission Protection Directive (BImSchV).

- Cooling gas monitoring of turbo generators

- Measurement of CO for coal mill monitoring

- Purity measurement of H2 in pressure swing adsorption plants

- Monitoring of CO2 in natural gas in natural gas conditioning plants

SICK S700 Gas Analyser

Features

- 5 different measurement principles available

- More than 60 measuring components to choose from

- 3 different housing variants for different fields of application

- Up to 3 analyser modules in a single housing

- Easy application-specific adaptation due to modular design

- Also suitable for zone 1 and zone 2 explosive environments (ATEX)

- Automatic adjustment with test gas or calibration cell

- Integrated self-monitoring and fault diagnosis

➡ T&D also distribute the range of SICK In-Situ Gas Analysers

Sick S700

Product Variations

Different housing variants are available depending on the location of use and ambient conditions:

SICK S700 Gas Analyser | Product Versions

A housing can accept up to 3 analyser modules. The table below shows the selection of analyser modules available. These modules are differentiated using the following measurement principles:

- NDIR spectroscopy (UNOR & MULTOR)

- Electrochemical cell (OXOR-E)

- Paramagnetic dumbbell principle (OXOR-P)

- Interference filter correlation (FINOR)

- Thermal conductivity measurement (THERMOR)

Simply combine modules from each the different groups to suit your application. The combination options are suitable for most housing types – For advise on which options to choose, please give us a call or email us with your specifications.

| Analyser Modules | ||

| Group 1 | Group 2 | Group 3 |

| UNOR | UNOR¹ | THERMOR |

| MULTOR | OXOR-E | OXOR-E |

| OXOR-E | OXOR-P | OXOR-P |

| OXOR-P | No Module | No Module |

| FINOR | ¹ Not compatible if FINOR selected in Group 1 | |

| No Module | ||

Technical SPECIFICATION

SICK s700 – Housing Types

Please note: The exact device specifications and performance data of the product may deviate from the information provided here, and depend on the application in which the product is being used and the relevant customer specifications.

SICK S700 sYSTEM

| Measured Values | Ar, CBrF3, CClF3, CCl2F2, CCl3F, CHClF2, CHCl3, CH2Cl2, CH2O, CH3Cl, CH3OH, (CH3)2O, CH4, CO, CO2, CS2, C2Cl2F4, C2Cl3F3, C2Cl4, C2HCl3, C2H2, C2H2Cl2, C2H2F4, C2H3Cl3, C2H4, C2H4Cl2, C2H5OH, C2H6, C3H4, C3H6, C3H7OH, C3H8, C3H8O2, C4H6, C4H8, C4H10, C4H8O, C4H9OH, C5H12, C6H10O, C6H12, C6H14, C7H16, C7H8, C8H10, He, H2, H2O, NH3, NO, N2O, O2, SF6, SO2 |

| Performance-Tested Measurands | CO, NO, O2, SO2 |

| Gas Flow Rate | No integrated sample gas pump: 5 l/h … 100 l/h With integrated sample gas pump: 30 l/h … 60 l/h |

| Sample Gas Temperature | 0 °C … +45 °C Temperature at analyser inlet |

| Process Pressure | Tubed gas lines –200 hPa … 1,000 hPa Hosed gas lines: –200 hPa … 300 hPa |

| Process Gas Humidity | Non-condensing |

| Dust Load | Free of dust and aerosols |

| Ambient Temperature | +5 °C … +45 °C |

| Storage Temperature | –20 °C … +70 °C |

| Ambient Pressure | 700 hPa … 1,200 hPa |

| Geographical Altitude | ≤ 2,000 m (above mean sea level) |

| Ambient Humidity | ≤ 95 % Relative humidity; non-condensing |

| Electrical Safety | CE, cCSAus |

| Enclosure Rating | IP20 |

| Analog Outputs | 4 outputs: 4 … 20 mA, + 500 Ω 0 … 10 V Electrically isolated |

| Analog Inputs | 2 inputs: 0/2/4 … 20 mA Option: 0 … 10 V DC |

| Digital Outputs | 8 relay contacts: Three relay outputs pre-set for failure, service and maintenance |

| Digital Inputs | 8 optical coupler inputs: Electrically isolated; freely programmable |

| Communication Interface | Modbus Type of fieldbus integration: RTU RS-232 |

| Number | 1 |

| Indication | LC Display |

| Operation | Menu-driven operation via LC-display and membrane keyboard |

| Menu Languages | German, English, French, Italian, Dutch, Polish, Swedish, Spanish |

| Model | 19″ rack enclosure with 3 rack units, for integration in cabinets |

| Dimensions (W x H x D) | 483 mm x 132.5 mm x 332 mm |

| Weight | 9 kg … 12 kg Depending on configuration |

| Power Supply | Voltage: 100 V / 115 V / 230 V Frequency: 48 … 62 Hz Power consumption: ≤ 150 W Depending on system configuration |

| Corrective Functions | Automatic testing and adjustment with test gases Manual adjustment with test gases |

| Options | Integrated sample gas pump (only with hosed gas lines) Tubed gas lines Up to 3 separate gas lines Flow sensor Humidity sensor Barometric pressure correction Sample gas pressure correction Sample point switching (max. 8 sample points) |

S710 Design

| Description | 19″ rack enclosure with 3 rack units, for integration in cabinets |

| Electrical Safety | CE |

| Enclosure Rating | IP20 |

| Dimensions (W x H x D) | 483 mm x 132.5 mm x 390 mm |

| Weight | 10 kg … 20 kg Depending on configuration |

| Sample Gas Connections | PVDF bulkhead fitting: for hose 6 x 1 mm Optional: Swagelok 6 mm / Swagelok ¼” |

S711 Design

| Description | 19″ rack enclosure with 3 rack units and reduced depth, for integration in cabinets |

| Electrical Safety | CE |

| Enclosure Rating | IP20 |

| Dimensions (W x H x D) | 483 mm x 132.5 mm x 390 mm |

| Weight | 9 kg … 19 kg Depending on configuration |

| Sample Gas Connections | PVDF bulkhead fitting: for hose 6 x 1 mm Optional: Swagelok 6 mm / Swagelok ¼” |

S715 Design

| Description | Wall-mounting enclosure with gas-tight separated analysing and electronic units, purgeable separately |

| Hazardous Area Approvals | ATEX: II 3G Ex nR II T6 |

| Electrical Safety | CE |

| Enclosure Rating | IP65 / NEMA 4x |

| Dimensions (W x H x D) | 555 mm x 470 mm x 288 mm |

| Weight | 20 kg … 30 kg Depending on configuration |

| Sample Gas Connections | Inside thread G1/4″: for screw-in fittings Option 1: PVDF bulkhead fitting: for hose 6 x 1 mm Option 2: Swagelok 6 mm Option 3: Swagelok ¼” |

| Auxiliary Gas Connections | Purge gas: Inside thread G1/4″: for screw-in fittings Option 1: Swagelok 8 mm Option 2: Swagelok 10 mm Option 3:Swagelok 3/8″ |

| Options | Intrinsically safe outputs for measured values |

Hazardous Area Gas Detection Equipment

S720 EX Design (For Hazardous Areas)

| Description | Flame-proof (Ex d) enclosure for use in ATEX Zone 1 certified areas |

| Hazardous Area Approvals | ATEX II 2G Ex db ia [ia] IIC T6 Gb II 2G Ex db ia IIC T6 Gb |

| Electrical Safety | CE |

| Enclosure Rating | IP65 / NEMA 7 |

| Dimensions (W x H x D) | 480 mm x 480 mm x 276 mm |

| Weight | 60 kg … 70 kg Depending on configuration |

| Sample Gas Connections | Inside thread G1/4″: for screw-in fittings Option 1: PVDF bulkhead fitting: for hose 6 x 1 mm Option 2: Swagelok 6 mm Option 3: Swagelok ¼” |

| Auxiliary Gas Connections | Purge gas: Inside thread G1/4″: for screw-in fittings |

| Options | Intrinsically safe outputs for measured values |

S721 EX Design (For Hazardous Areas)

| Description | Flame-proof (Ex d) enclosure for use in ATEX Zone 1 certified areas with large analyser unit for maximum system configuration |

| Hazardous Area Approvals | ATEX II 2G Ex db ia [ia] IIC T6 Gb II 2G Ex db ia IIC T6 Gb |

| Electrical Safety | CE |

| Enclosure Rating | IP65 / NEMA 7 |

| Dimensions (W x H x D) | 596 mm x 480 mm x 300 mm |

| Weight | 90 kg … 100 kg Depending on configuration |

| Sample Gas Connections | Inside thread G1/4″: for screw-in fittings Option 1: PVDF bulkhead fitting: for hose 6 x 1 mm Option 2: Swagelok 6 mm Option 3: Swagelok ¼” |

| Auxiliary Gas Connections | Purge gas: Inside thread G1/4″: for screw-in fittings |

| Options | Intrinsically safe outputs for measured values |

Detecting Harmful Toxic & Flammable Gases – Saving Lives

SICK s700 – Analyser Modules

FINOR analyser module

| Phase-Out | This system component will be phased out soon – Speak to T&D for more information |

| Description | Rugged IR analyser with no moving parts for measuring gases in vol. % range |

| Measurement Principles | Interference filter correlation |

| Measuring Ranges | CH4: 0 … + 2 Vol.-% CO: 0 … + 0.5 Vol.-% CO2: 0 … + 0.1 Vol.-% SF6 : 0 … + 10 Vol.-% |

| Response Time (t90) | ≤ 25s Typical at 60 l/h, depending on cuvette length, gas flow & number of measuring components |

| Sensitivity drift | ≤ 1 %: per week |

| Zero point drift | ≤ 1.5 %: of smallest measuring range per week |

| Material in contact with media | Viton B, PVDF, stainless steel 1.4571, Aluminium, Calciumfluorid |

MULTOR Analyser Module

| Description | Multi-component NDIR analyser for continuous measurement of up to 3 IR-absorbing gases and H2O for internal interference sensitivity correction |

| Measurement Principles | NDIR spectroscopy |

| Measuring Ranges | CH4: 0 … 470 ppm / 0 … 100 Vol.-% CO: 0 … 160 ppm / 0 … 100 Vol.-% CO2: 0 … 100 ppm / 0 … 100 Vol.-% NO: 0 … 190 ppm / 0 … 100 Vol.-% SO2: 0 … 85 ppm / 0 … 100 Vol.-% |

| Certified Measuring Ranges | CO: 0 … 200 mg/m³ NO: 0 … 250 mg/m³ SO2: 0 … 250 mg/m³ Certified according to EN 14181:2004 |

| Response Time (t90) | ≤ 25s Typical at 60 l/h, depending on cuvette length, gas flow & number of measuring components |

| Sensitivity drift | ≤ 1 %: of measuring range full scale per week |

| Zero point drift | ≤ 1 %: of smallest measuring range per week |

| Conformities | 2001/80/EC (13. BImSchV) TA-Luft (Prevention of Air Pollution) EN 14181:2004 |

| Material in contact with media | Viton B, PVDF, Calciumfluorid, Bariumfluorid, stainless steel 1.4571, gold, Aluminium |

| Corrective Functions | Manual or automatic adjustment with test gases or adjustment cell |

THERMOR Analyser Module

| Description | Heat conductivity analyser for the determination of concentrations in binary or quasi-binary gas mixtures |

| Measurement Principles | Thermal conductivity measurement |

| Measuring Ranges | H2 in Ar: 0 … 1 Vol.-% / 0 … 100 Vol.-% H2 in CH4: 0 … 1 Vol.-% / 0 … 100 Vol.-% H2 in CO2: 0 … 1 Vol.-% / 0 … 100 Vol.-% H2 in blast furnace gas: 0 … 1 Vol.-% / 0 … 100 Vol.-% H2 in N2: 0 … 1 Vol.-% / 0 … 100 Vol.-% H2 in O2: 0 … 1 Vol.-% / 0 … 100 Vol.-% Other measuring ranges & components on request |

| Response Time (t90) | ≤ 20s At a gas flow of 60 l/h |

| Sensitivity drift | ≤ 1 %: of measuring range full scale per week |

| Zero point drift | ≤ 1 %: of smallest measuring range per week |

| Material in contact with media | Glass, stainless steel 1.4571, PVDF (HCl resistant version) |

| Corrective Functions | Manual or automatic adjustment with test gases |

UNOR Analyser Module

| Description | Highly selective NDIR analyser for continuous measurement of almost any gas component which absorbs in the infra-red spectral range |

| Measurement Principles | NDIR spectroscopy |

| Measuring Ranges

(More than 60 measuring components available) |

CH4: 0 … 100 ppm / 0 … 100 Vol.-% C2H2: 0 … 300 ppm / 0 … 100 Vol.-% C2H4: 0 … 300 ppm / 0 … 100 Vol.-% Frigen 11, CCl3F: 0 … 500 ppm / 0 … 50 Vol.-% Frigen 134a, C2H2F4: 0 … 100 ppm / 0 … 100 Vol.-% Frigen 22, CHClF2: 0 … 100 ppm / 0 … 100 Vol.-% C2H6: 0 … 100 ppm / 0 … 100 Vol.-% C2H2Cl2: 0 … 500 ppm / 0 … 30 Vol.-% C3H6: 0 … 300 ppm / 0 … 100 Vol.-% C3H8: 0 … 100 ppm / 0 … 100 Vol.-% C4H10: 0 … 100 ppm / 0 … 100 Vol.-% C5H12: 0 … 300 ppm / 0 … 100 Vol.-% C6H14: 0 … 300 ppm / 0 … 10 Vol.-% CO: 0 … 20 ppm / 0 … 100 Vol.-% CO2: 0 … 10 ppm / 0 … 100 Vol.-% NH3: 0 … 300 ppm / 0 … 100 Vol.-% NO: 0 … 75 ppm / 0 … 100 Vol.-% N2O: 0 … 50 ppm / 0 … 100 Vol.-% SF6:0 … 50 ppm / 0 … 100 Vol.-% SO2: 0 … 85 ppm / 0 … 100 Vol.-% |

| Certified Measuring Ranges | CO: 0 … 100 mg/m³ NO: 0 … 100 mg/m³ SO2: 0 … 100 mg/m³ Certified according to EN 14181:2004 |

| Response Time (t90) | 3s Typical at 60 l/h, depending on cell length & gas flow |

| Sensitivity drift | ≤ 1 %: of measuring range full scale per week |

| Zero point drift | ≤ 1 %: of smallest measuring range per week |

| Conformities | 2001/80/EC (13. BImSchV) 2000/76/EC (17. BImSchV) 27. BImSchV TA-Luft (Prevention of Air Pollution) EN 14181:2004 |

| Material in contact with media | Viton B, PVDF, Calciumfluorid, Bariumfluorid, stainless steel 1.4571, gold, Aluminium |

| Corrective Functions | Manual or automatic adjustment with test gases or adjustment cell |

Gas, Liquid & Bulk Solids Sensors, Analysers & Detectors from SICK

OXOR-E Analyser Module

| Description | Determination of oxygen content using an electrochemical cell |

| Measurement Principles | Electrochemical cell |

| Measuring Ranges | O2: 0 … 10 Vol.-% / 0 … 25 Vol.-% |

| Certified Measuring Ranges | O2: 0 … 25 Vol.-% Certified according to EN 14181:2004 |

| Response Time (t90) | ≤ 20s Typical at 60 l/h, depending on gas flow |

| Sensitivity drift | ≤ 1 %: of measuring range full scale per week |

| Zero point drift | ≤ 2 %: of smallest measuring range per week |

| Process Pressure | Analyser inlet: –200 hPa … 300 hPa Relative |

| Conformities | 2001/80/EC (13. BImSchV) 2000/76/EC (17. BImSchV) 27. BImSchV TA-Luft (Prevention of Air Pollution) EN 14181:2004 |

| Material in contact with media | Viton B, PVDF, stainless steel 1.4571 |

| Corrective Functions | Manual or automatic adjustment with test gases |

OXOR-P analyser module

| Description | Accurate oxygen analyser which operates according to the paramagnetic measurement principle |

| Measurement Principles | Paramagnetic dumbbell principle |

| Measuring Ranges | O2: 0 … 1 Vol.-% / 0 … 100 Vol.-% |

| Certified Measuring Ranges | O2: 0 … 25 Vol.-% Certified according to EN 14181:2004 |

| Response Time (t90) | ≤4s Typical at a gas flow of 60 l/h |

| Sensitivity drift | ≤ 1 %: of measuring range full scale per week |

| Zero point drift | ≤ 1 %: of smallest measuring range per week Measuring ranges smaller 5 Vol%: ≤ 0.05 Vol.-%: per week |

| Conformities | 2001/80/EC (13. BImSchV) 2000/76/EC (17. BImSchV) 27. BImSchV TA-Luft (Prevention of Air Pollution) EN 14181:2004 |

| Material in contact with media | Viton B, PVDF, glass, stainless steel 1.4571, platinum, nickel, Aluminium |

| Corrective Functions | Manual or automatic adjustment with test gases |

| Remark | Special versions with highly solvent-resistant or highly corrosion-resistant measuring cells available |

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES & Hazardous Areas

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters