Ex e Lighting – Increased Safety Hazardous Area Technor EVF-P Fluorescent Lighting

Zone 1 & Zone 21 Lighting

Fluorescent Lighting for Hazardous Areas – Zone 1, Zone 21, Zone 2 & Zone 22 Applications

Thorne & Derrick, the Specialist Distributors of Hazardous Area Lighting can provide competitive prices and supply from stock the complete range of Technor products including electrical enclosures and junction boxes.

Technor’s EVF-P is a fluorescent lighting fixture suitable for hazardous area lighting and offers offers Ex-e IIC mode of Explosion Protection and has a polycarbonate lamp housing which is three layers extrusion UV resistant.

Technor EVF-P Ex e lighting is classified to international hazardous area classifications with ATEX and TRCU certification, with ingress protection IP66 and an operational ambient temperature range of -20°C to +55°C.

Circular shape of the ex lighting grants the best possible “CX” factor, therefore it is less affected by wind dusts, no flat surfaces to avoid pollution and dirty bunching.

Technor EVF-P fluorescent lighting fixtures are manufactured with a high resistance cylindrical polycarbonate lamp housing with end cups made from corrosion resistant copper free aluminium. Optionally an off-shore painting cycle can be provided to allow for use within marine environments and all EVF-P fixtures are supplied ready for loop in-loop out facility with 4sqmm cable.

Thorne & Derrick, a trusted specialist distributor of hazardous area lighting, offers competitive pricing and in-stock availability for the complete range of Technor hazardous area lighting solutions, including electrical enclosures and explosion-proof junction boxes. Our extensive inventory ensures quick delivery for ATEX-certified lighting designed for Zone 1, Zone 21, Zone 2, and Zone 22 applications.

Technor EVF-P Fluorescent Lighting – Technical Features

Technor EVF-P Fluorescent Lighting

Technical Specification

Technor’s EVF-P fluorescent fixtures offer Ex-e IIC protection, featuring a durable, UV-resistant polycarbonate housing. ATEX and TRCU certified with IP66 ingress protection, they withstand dust, water, and temperatures from -20°C to +55°C.

Designed for efficiency, the circular shape minimises wind and dust impact while preventing dirt accumulation. Built with corrosion-resistant materials, an optional offshore coating enhances marine durability.

Easy to install with a loop-in/loop-out facility for 4sqmm cables, Technor EVF-P ensures reliable performance in explosive atmospheres, meeting stringent safety standards for hazardous area lighting.

| TECHNOR EVF-P Hazardous Area Lighting | Lighting Specification |

| Material | End cups in aluminium with low content of copper / Light housing in polycarbonate |

| IP rating | IP66/IK10 according to EN 62262:2002 |

| Ambient temperature range | -20°C to +55°C |

| Approvals | INERIS 02ATEX0039X (standard) / TR CU (marking upon request, ordering code to be required) |

| Gaskets | O-ring made of Nitrile Rubber (NBR) |

| Surface treatment | End cups painted by green colour polyurethane painting cycle RAL6003 (other colour available upon request) |

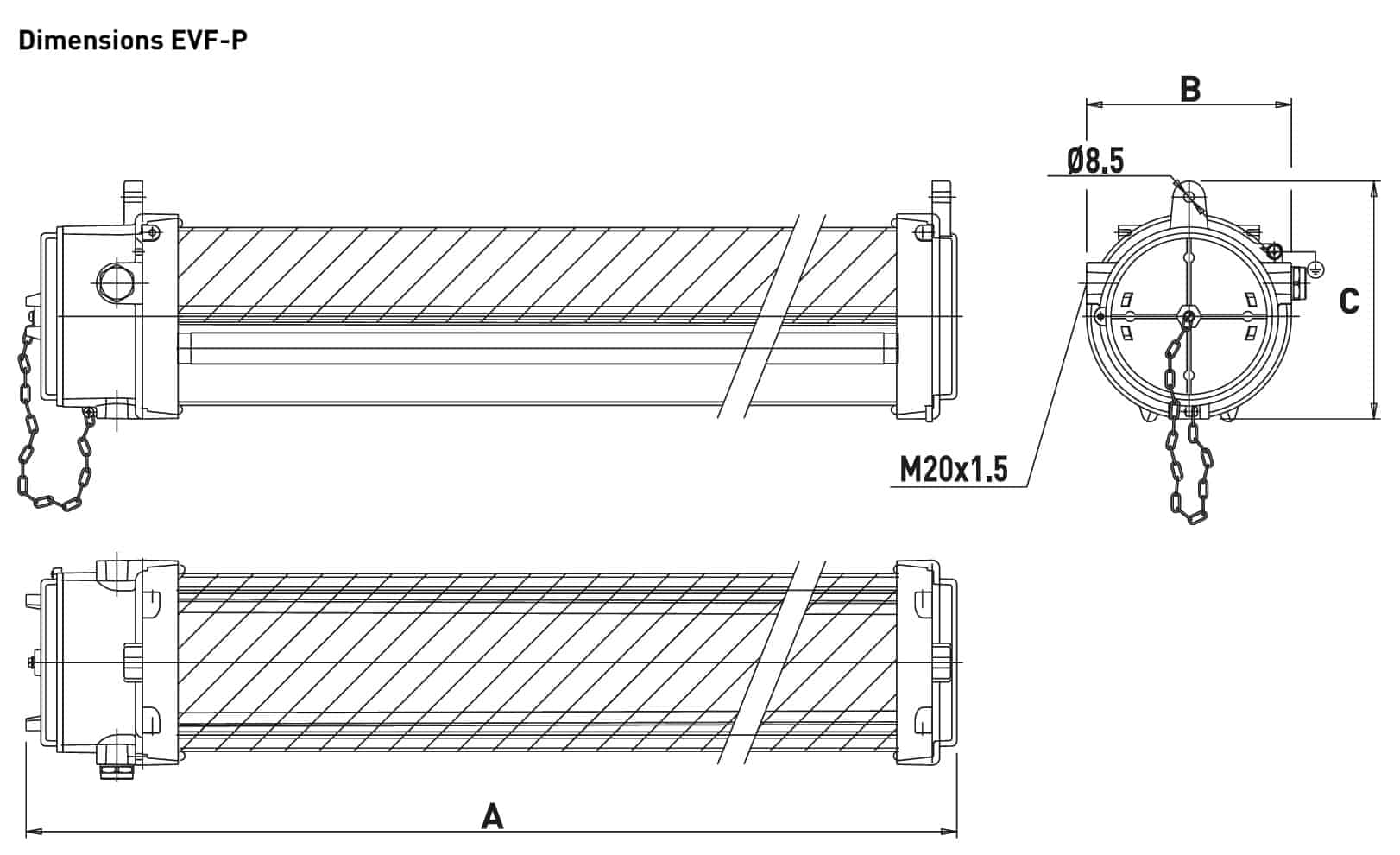

| Entries | N° 2 entries M20x1.5. One plugged-off by Ex d brass nickel chrome plated plug and relevant gasket. |

| Hardware and screws | AISI304 Stainless steel external hardware and screws |

| Lamps | EVF-P series lighting fixtures are suitable for two pins fluorescent lamps G13 socket Philips TL-D or equivalent (lamps excluded) |

| Ballast | High frequency electronic ballast conforming with EN 60079 – 18 and IEC 60079 – 18 |

| Rated Operation Voltage (UE) | 110–240 (normal service) – 230-240 (Emergency service) |

| Frequency | 0/50 – 60 Hz |

| Power Factor | >0.95 |

| Accessories available upon request | AISI304 Pole mounting kit / AISI304 Ceiling / Wall mounting kit / AISI304 Suspension mounting kit / 3° bottom entry M20x1,5 / AISI304 protection guard / Mounting kit in stainless steel AISI316 |

| Operating Principles |

Available EVF-P lighting fixtures for emergency service of one tube:

– 90 minutes; guarantees 60’ duration with constant flux (emergency lumen factor 17%) and 30’ with decreasing flux

– 120 minutes (emergency lumen factor 10%)

– 180 minutes; constant flux (emergency lumen factor 9%)

|

Technor EVF-p Lighting – Normal Service

Technor products meet the requirements of the joint European standards (ATEX regulations) and each individual component are certified in accordance with specific Ex certification requirements.

| Technor Part Number | Ex e Lighting Code | Power (W) | Dimensions (mm) | Weight (kg) | ||

| A | B | C | ||||

| EVF-P 118-Ex emb | A030111180011 | 1X18 | 764 | 176 | 194 | 6.50 |

| EVF-P 218-Ex emb | A030112180011 | 2X18 | 764 | 176 | 194 | 6.50 |

| EVF-P 136-Ex emb | A030111360011 | 1X36 | 1374 | 176 | 194 | 8.50 |

| EVF-P 236-Ex emb | A030112360011 | 2X36 | 1374 | 176 | 194 | 8.50 |

| EVF-P 158-Ex emb | A030111580011 | 1X58 | 1680 | 176 | 194 | 9.50 |

| EVF-P 258-Ex emb | A030112580011 | 2X58 | 1680 | 176 | 194 | 10.50 |

Technor EVF-p Lighting – Emergency Service

Circular shape of the ex lighting grants the best possible “CX” factor, therefore it is less affected by wind dusts, no flat surfaces to avoid pollution and dirty bunching.

| Technor Part Number | Ex e Lighting Code | Power (W) | Emergency Duration | Dimensions (mm) | Weight (kg) | ||

| A | B | C | |||||

| EVF-P 118 LE-P-90 Ex demb | A030211180111 | Single 18 Watt Fluorescent Light Fittings | 90′ | 764 | 176 | 194 | 9.00 |

| EVF-P 118 LE-P-120 Ex demb | A030211180211 | 1X18 | 120′ | 764 | 176 | 194 | 10.00 |

| EVF-P 218 LE-P-90 Ex demb | A030212180111 | 2X18 | 90′ | 764 | 176 | 194 | 9.00 |

| EVF-P 218 LE-P-120 Ex demb | A030212180211 | 2X18 | 120′ | 764 | 176 | 194 | 10.00 |

| EVF-P 136 LE-P-90 Ex demb | A030211360111 | 1X36 | 90′ | 1374 | 176 | 194 | 11.00 |

| EVF-P 136 LE-P-120 Ex demb | A030211360211 | 1X36 | 120′ | 1374 | 176 | 194 | 12.00 |

| EVF-P 136 LE-P-180 Ex demb | A030211360311 | 1X36 | 180′ | 1374 | 176 | 194 | 12.50 |

| EVF-P 236 LE-P-90 Ex demb | A030212360111 | 2X36 | 90′ | 1374 | 176 | 194 | 11.00 |

| EVF-P 236 LE-P-120 Ex demb | A030212360211 | 2X36 | 120′ | 1374 | 176 | 194 | 12.00 |

| EVF-P 236 LE-P-180 Ex demb | A030212360311 | 2X36 | 180′ | 1374 | 176 | 194 | 12.50 |

| EVF-P 158 LE-P-90 Ex demb | A030211580111 | 1X58 | 90′ | 1680 | 176 | 194 | 12.00 |

| EVF-P 158 LE-P-120 Ex demb | A030211580211 | 1X58 | 120′ | 1680 | 176 | 194 | 13.00 |

| EVF-P 158 LE-P-180 Ex demb | A030211580311 | 1X58 | 180′ | 1680 | 176 | 194 | 13.50 |

| EVF-P 258 LE-P-90 Ex demb | A030212580111 | 2X58 | 90′ | 1680 | 176 | 194 | 12.00 |

| EVF-P 258 LE-P-120 Ex demb | A030212580211 | 2X58 | 120′ | 1680 | 176 | 194 | 13.00 |

| EVF-P 258 LE-P-180 Ex demb | A030212580311 | 2X58 | 180′ | 1680 | 176 | 194 | 13.50 |

Technor EVF-P Fluorescent Lighting – certifications

II 2 GD

- Ex e mb IIC T4 Gb (Normal service) / Ex d e mb IIC T4 Gb (Emergency service)

- EX de IIC T4 Gb (available upon request)

- Ex tb IIIC T85°C Db IP66

Under IEC Ex directive, junction boxes and enclosures are suitable for IIC group of gases/dusts only

Approvals

- Certified 02ATEX0039X (standard) / TR CU (marking upon request, ordering code to be required)

Technor electrical equipment and Exd enclosures makes it possible to safely use instruments, lights, motors and equipment requiring electric power in potentially explosive atmospheres and hazardous areas.

Technor is part of the Marechal Electrical Group, leading manufacturer of ATEX plugs and sockets for hazardous areas and explosive atmospheres.

Technor hazardous area explosion proof and protected electrical equipment is specified in the following applications : oil refineries and offshore rigs, power stations, sugar refining, mines, sewage treatment plants, grain handling and storage, chemical plants, aircraft refuelling and hangars, printing, paper and textiles.

Technor products meet the requirements of the joint European standards (ATEX regulations) and each individual component are certified in accordance with specific Ex certification requirements.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control