Specifying Compliant ATEX Doors for Hazardous Areas & Explosive Atmospheres | By Dynaco

Published 28 Apr 2020

Specifying Doors for Energy Savings & Maximum Safety in Explosive Atmospheres

-

uploaded by Chris Dodds | Sales & Marketing Manager with Thorne & Derrick International

Welcome to our online Tutorial hosted by Yves Degroote from Dynaco, the leading manufacturer of high performance, high speed doors for industrial, hazardous areas and explosive atmosphere applications.

Yves provides an excellent technical and terminological explanation of the ATEX Directive and the commercial features and benefits of their Dynaco S-5 market leading ATEX certified door. The origins of ATEX is covered and the Directive’s role in accident and incident prevention in the oil, gas and chemicals industries.

The intention of this Tutorial is to raise industry awareness of potential non-compliance risks in the hazardous area industries – we present an innovative and ATEX compliant solution which when carefully understood can actually deliver proven economic benefits through reduced energy costs and improved worksite productivity with carbon footprint reductions and Health & Safety improvements.

ATEX Doors for Hazardous Areas

Tutorial Overview. Run Time 31.15.

- What is ATEX & Hazardous Area Classification – Why? Where? How? Who? When?

- Worst Situation Scenario’s – Video & Accident History

- ATEX Certification – Summary

- ATEX Zones – What is the Level of Explosion Risk for Flammable Hazardous Gas & Vapour

- ATEX Zones – What is the Level of Explosion Risk for Combustible Ducts

- Explosive Gas and Dust Groups & Temperature Class Ratings (T-Class)

- Overcoming Specification & ATEX Compliance Challenges

- No Doors, Manual Doors or High Speed Doors?

- Demonstrating Cost Justification Through ROI To End Clients

- Partioning In Hazardous Area Zones & Reducing Footprint Costs of ATEX Classified Zones

- How & Why To Specify High Speed Doors To Ensure Compliance with ATEX 2014/34/EU

Energy Savings

Ask us to calculate your temperature losses + confirm the expected annual energy savings by installing high speed doors. Should you be interested to receive a FREE ROI REPORT to assess the energy efficiency impact Dynaco doors could have on your facility contact us.

More Benefits

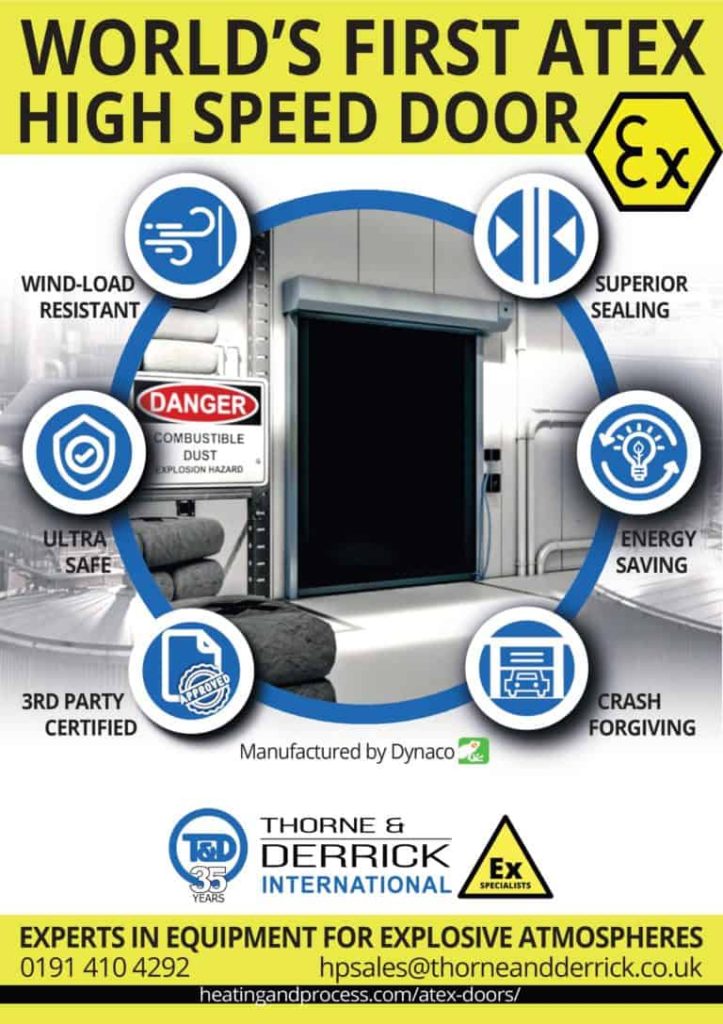

Market Leading ATEX Doors | Compliant & Certified

ATEX DOORS

High Speed Roll-up Doors for Hazardous Areas & Explosive Atmospheres

Thorne and Derrick are the Exclusive UK Distribution Partner for Dynaco ATEX Doors for Hazardous Areas – this range of doors, certified according to the ATEX Directive, are high speed and roll-up design. The doors provide a unique safety solution for clients who need to maintain or improve workflow in hazardous area locations and explosive atmospheres.

To enable the safe storage, transportation, heating and handling of flammable liquids contained in IBC containers and drums we stock a complete range of heating jackets and drum handling equipment certified according to the ATEX Directive.

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

leaders in ATEX Innovation To The Hazardous Area Industries

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery