Hazardous Area Connectors ATEX Zone 1 | Amphenol Star-Line EX

Amphenol Star-Line EX Hazardous Area Connectors

Hazardous Area Connectors

Star-Line EX | ATEX & IECEx Connectors

Zone 1 Hazardous Areas | Explosion Proof

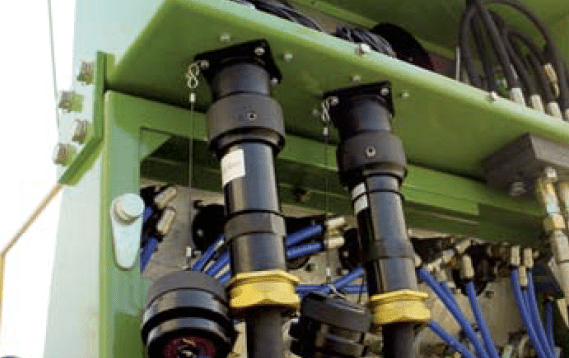

Amphenol Star-Line EX connectors are cylindrical in shape with a metal finish, threaded coupling power and signal connectors for use in harsh environments and Zone 1 certified hazardous areas. The Star-Line EX Series is a hybrid form of the parent Star-Line industrial connector range.

Classified facilities such as petrochemical refineries and land or offshore drilling systems are just a few of the applications for this broad range of plugs, inline receptacles and panel mount receptacles.

The Star-Line EX is certified to the latest IECEx and ATEX EN60079 standards, as well as the current GOST standards.

Hazardous Area Certifications

- ATEX Certificate #03ATEX1101X Ex d IIC T6 Gb

- IECEx Certificate # SIR 10.0064X

- CE IP68-8 rated (Dust-tight & indefinite immersion)

- Cenelec certified EEXd IIC-T6, flame and dust proof

- ATEX/IECEx Rated to EExd, and EExde, T6 Gas & Dust Ratings

- Rated for use up to 1000V AC/DC

- GOST R Certified #POCC MX. A II 96.B00012

Amphenol Star-Line EX

Features

The Amphenol Star-Line EX series of connectors is comprised of metallic bodied plug and receptacle shells, to form inline cable connections.

Externally the main bodies are fitted with suitably certified cable glands. Internally the main bodies each contain an insulator insert fitted with solder or pressure type contacts of either a pin or socket variety. The plug and receptacle shells together form an in-line connector. When connected they form a spigotted flamepath and are mechanically interlocked by means of a threaded nut retained by a grub screw.

Additionally, the receptacle connector is available in a bulkhead mounted version that contains an externally threaded flamepath for mounting to certified EX enclosures with suitable internal mating thread. This variety of bulkhead mount connector, must be internally potted, as described within this document.

Hard Anodic Coating – All machined aluminium parts finished with a hard, scratch-resistant coating per MIL-A-8625, Type III. Dielectric strength 1800 volts. Heat resistance of 750° F

Reversible Inserts – A full range of contact inserts for power, signal and mixed applications are available. All are interchangeable and reversible to suit specific needs.

Easily Accessible Wire Terminals – Conductors are readily terminated to contacts. Cable housings are slipped over conductors or leads after terminating. Cumbersome handling and seating of inserts with conductors attached is eliminated.

Large Wiring Space – Ample wiring space is provided in cable housings and hardware.

High Tensile Strength Aluminium – Bar Stock Components precision machined. Points of impact designed for extra strength.

Cable Options – Star-Line EX Series can be terminated onto unarmoured or armoured and sheathed cables built to IEEE-45 / UL1309, IEC, BS, DIN and JIC standards. Flexible cables like SOOW-A, W, G-GC and DLO constructions can also be used with these connectors.

EX Cable Glands – Wide variety of glands are available for Star-Line EX connectors.

Insert Variety – A broad range of inserts are offered ranging from single-contact to 143 contacts. High amperage up to 1135 amps at 1000V / AC or DC. Contacts are high quality copper with silver plating. (Gold plating available as an option) Composite inserts for power, control and instrumentation service available.

RADSOK® High Amperage Contacts – Special arrangements are available with RADSOK high amperage contacts. Standard Star-Line EX inserts are not interchangeable with new RADSOK contact insert arrangements.

RoHS Compliant Product Available – Contact Thorne & Derrick International

Amphenol Star-Line EX offers a full range of hardware styles

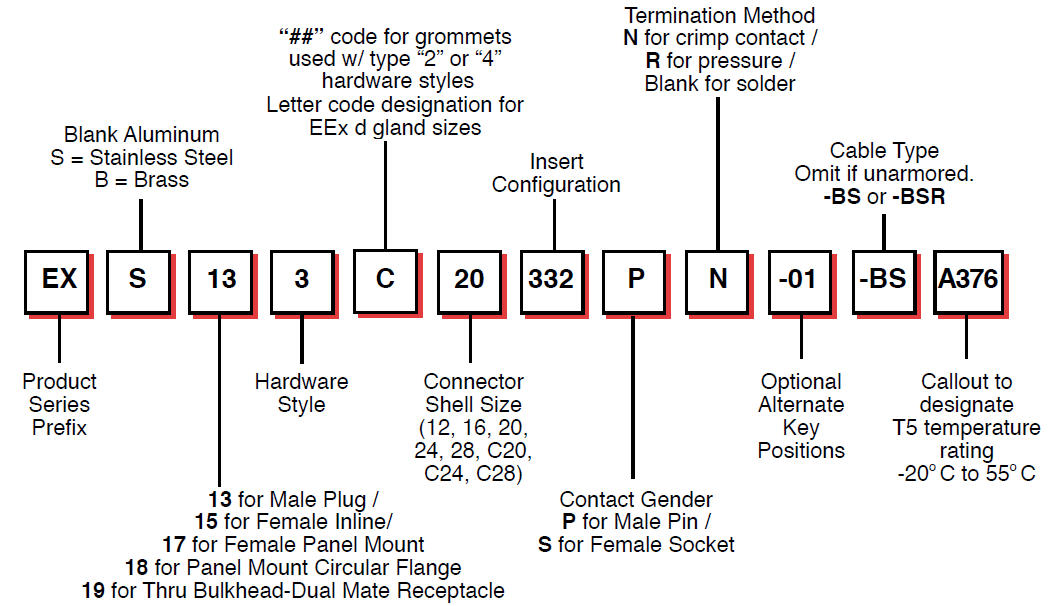

How to Order Amphenol Star-Line EX

The range is comprised of seven body (forms) sizes, each with a number of pin/socket size combinations between 1 and 143 contacts. The connector shell size, pin configuration and rating are reflected in the individual type designations.

Connector Order Code Logic

➡ Call our expert sales team for advice and assistance.

Amphenol Star-Line EX Connectors | How to Order

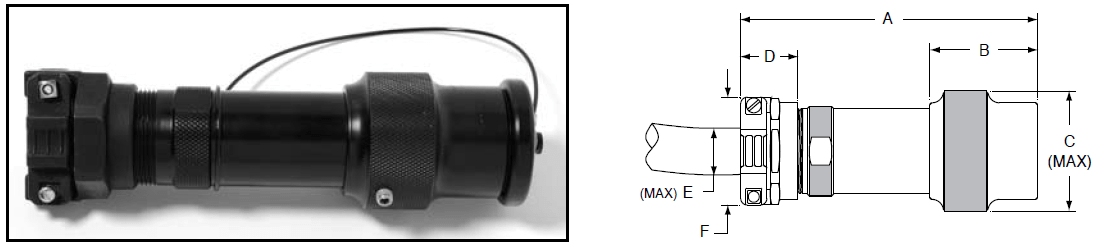

Amphenol Star-Line EX Plugs

Plug with Mechanical Clamp (Potting Required)

Star-Line EX-13-2 Style

Amphenol Star-Line EX-13-2 Plug

| Connector Dimensions | ||||||

| Shell | A* | B* | C | D | E | F |

| 12 | 7-7/16 (189) | 3-9/16 (91) | 2-1/8 (54) | 2 (51) | 15/16 (24) | 2-3/8 (60) |

| 16 | 9-1/2 (241) | 2-5/8 (67) | 2-1/16 (52) | 1-7/16 (37) | 3 (76) | |

| 20 | 9-9/16 (243) | 3-1/8 (79) | 2-1/8 (54) | 1-15/16 (49) | 3-3/4 (95) | |

| 24 | 9-5/8 (245) | 3-5/8 (92) | 2-3/16 (56) | 2-7/16 (62) | 4-1/2 (114) | |

| 28 | 9-11/16 (246) | 4-1/8 (105) | 2 1/4 (57) | 2-7/8 (73) | 5-1/8 (130) | |

Plug with EEx d Gland (Potting Not Required)

Star-Line EX-13-3 Style

Amphenol Star-Line EX-13-3 Plug

| Connector Dimensions | ||||

| Shell | A* | B* | C | Gland Thread |

| 12 | 6-1/16 (154) | 3-9/16 (91) | 2-1/8 (54) | M25 |

| 16 | 8-1/16 (205) | 2-5/8 (67) | M40 | |

| 20 | 3-1/8 (79) | M50 | ||

| 24 | 3-5/8 (92) | M63 | ||

| 28 | 4-1/8 (105) | M75 | ||

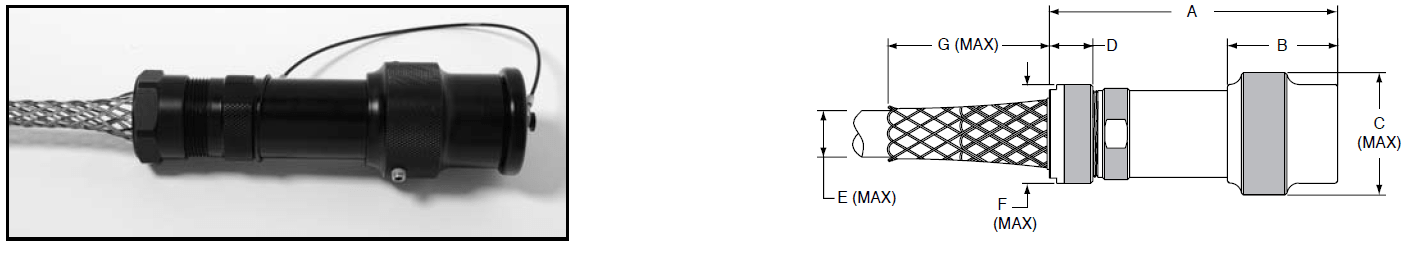

Plug with Basket weave Cable Grip (Potting Required)

Star-Line EX-13-4 Style

Amphenol Star-Line EX-13-4 Plug

| Connector Dimensions | |||||||

| Shell | A* | B* | C | D | E | F | G |

| 12 | 6-1/16 (154) | 3-9/16 (91) | 2-1/8 (54) | 1-1/4 (32) | 15/16 (24) | 1-9/32 (33) | 8 (203) |

| 16 | 8-1/16 (205) | 2-5/8 (67) | 1-7/16 (37) | 1-25/32 (45) | 10-1/2 (267) | ||

| 20 | 3-1/8 (79) | 1-15/16 (49) | 2-9/32 (58) | 14-1/2 (368) | |||

| 24 | 3-5/8 (92) | 2-7/16 (62) | 2-25/32 (71) | 17-1/2 (445) | |||

| 28 | 4-1/8 (105) | 2-7/8 (73) | 3-9/32 (83) | 19 (483) | |||

*Notes: For “C” length inserts, add 1/2” to both dimensions “A” & “B”.

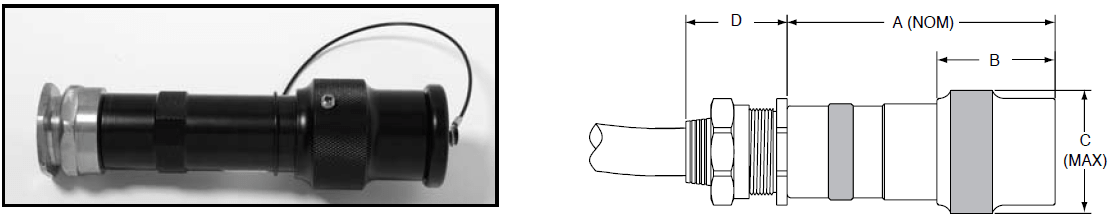

Amphenol Star-Line EX Inline Receptacles

In-line Receptacle with Mechanical Clamp (Potting Required)

Star-Line EX-15-2 Style

Amphenol Star-Line EX-15-2 Inline Receptacle

| Connector Dimensions | ||||||

| Shell | A* | B* | C | D | E | F |

| 12 | 7 (178) | 1-7/16 (37) | 1-1/2 (38) | 2 (51) | 15/16 (24) | 2-3/8 (60) |

| 16 | 9-1/16 (230) | 2 (51) | 2-1/16 (52) | 1-7/16 (37) | 3 (76) | |

| 20 | 9-1/8 (232) | 2-1/2 (64) | 2-1/8 (54) | 1-15/16 (49) | 3-3/4 (95) | |

| 24 | 9-3/16 (233) | 3 (76) | 2-3/16 (56) | 2-7/16 (62) | 4-1/2 (114) | |

| 28 | 9-1/4 (235) | 3-1/2 (89) | 2 1/4 (57) | 2-7/8 (73) | 5-1/8 (130) | |

Inline REceptacle with EEx d Gland (Potting Not Required)

Star-Line EX-15-3 Style

Amphenol Star-Line EX-15-3 Inline Receptacle

| Connector Dimensions | ||||

| Shell | A* | B* | C | Gland Thread |

| 12 | 5-5/8 (143) | 1-7/16 (37) | 1-1/2 (38) | M25 |

| 16 | 7-5/8 (194) | 2 (51) | M40 | |

| 20 | 2-1/2 (64) | M50 | ||

| 24 | 3 (76) | M63 | ||

| 28 | 3-1/2 (89) | M75 | ||

Inline Receptacle with Basket weave Cable Grip (Potting Required)

Star-Line EX-15-4 Style

Amphenol Star-Line EX-15-4 Inline Receptacle

| Connector Dimensions | |||||||

| Shell | A* | B* | C | D | E | F | G |

| 12 | 6-1/4 (159) | 1-7/16 (37) | 1-1/2 (38) | 1-1/4 (32) | 15/16 (24) | 1-9/32 (33) | 8 (203) |

| 16 | 8-1/4 (210) | 2 (51) | 1-7/16 (37) | 1-25/32 (45) | 10-1/2 (267) | ||

| 20 | 2-1/2 (64) | 1-15/16 (49) | 2-9/32 (58) | 14-1/2 (368) | |||

| 24 | 3 (76) | 2-7/16 (62) | 2-25/32 (71) | 17-1/2 (445) | |||

| 28 | 3-1/2 (89) | 2-7/8 (73) | 3-9/32 (83) | 19 (483) | |||

*Notes: For “C” length inserts, add 1/2” to both dimensions “A” & “B”.

Amphenol Hazardous Area Connectors

Amphenol Star-Line EX Panel Mount Receptacles

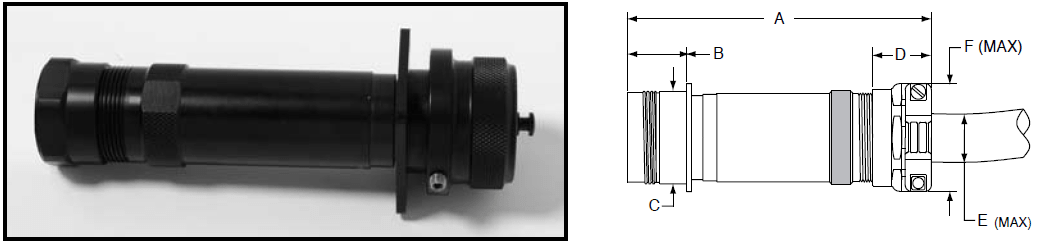

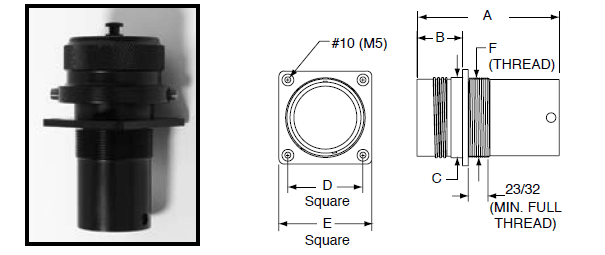

Panel Mount Receptacle (Potting Required)

Star-Line EX-17-1 Style

Amphenol Star-Line EX-17-1 Panel Mount Receptacle

| Connector Dimensions | ||||||

| Shell | A* | B* | C | D | E | F |

| 12 | 4 7/16 | 1.765 | 1-1/2 (38) | 1.654 (42) | 2-1/4 (57) | M40 |

| 16 | 2 (51) | 2.047 (52) | 2-5/8 (67) | M50 | ||

| 20 | 2-1/2 (64) | 2.441 (62) | 3 (76) | M63 | ||

| 24 | 3 (76) | 2.835 (72) | 3-1/2 (89) | M75 | ||

| 28 | 3-1/2 (89) | 3.228 (82) | 4 (102) | M90 | ||

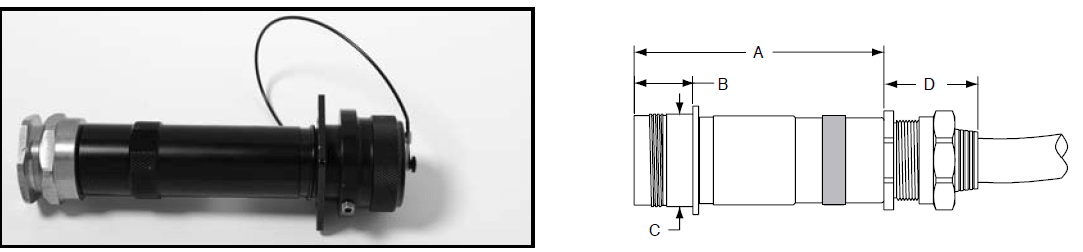

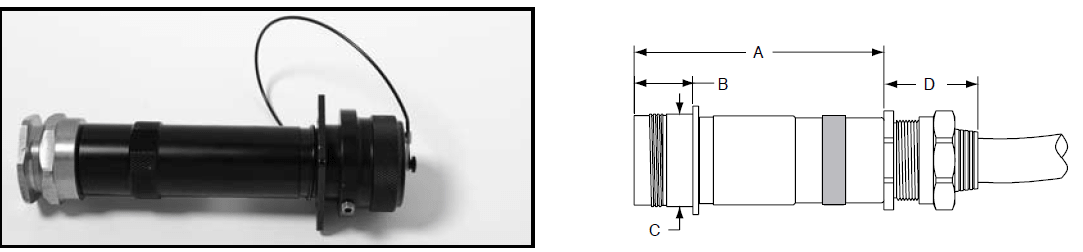

Fixed Inline Receptacle (Potting Required)

Star-Line EX-17-2 Style

Amphenol Star-Line EX-17-2 Fixed Inline Receptacle

| Connector Dimensions | ||||||

| Shell | A* | B* | C | D | E | F |

| 12 | 7 (178) | 1-7/16 (27) | 1-1/2 (38) | 2 (51) | 15/16 (24) | 2-3/8 (60) |

| 16 | 9-1/16 (230) | 2 (51) | 2-1/16 (52) | 1-7/16 (37) | 3 (76) | |

| 20 | 9-1/8 (229) | 2-1/2 (64) | 2-1/8 (54) | 1-15/16 (49) | 3-3/4 (95) | |

| 24 | 9-3/16 (233) | 3 (76) | 2-3/16 (56) | 2-7/16 (62) | 4-1/2 (114) | |

| 28 | 9-1/4 (235) | 3-1/2 (89) | 2 1/4 (57) | 2-7/8 (73) | 5-1/8 (130) | |

Fixed Inline REceptacle with EEx d Gland (Potting Not Required)

Star-Line EX-17-3 Style

Amphenol Star-Line EX-17-3 Fixed Inline Receptacle

| Connector Dimensions | ||||

| Shell | A* | B* | C | Gland Thread |

| 12 | 5-5/8 (143) | 1-7/16 (37) | 1-1/2 (38) | M25 |

| 16 | 7-5/8 (194) | 2 (51) | M40 | |

| 20 | 2-1/2 (64) | M50 | ||

| 24 | 3 (76) | M63 | ||

| 28 | 3-1/2 (89) | M75 | ||

Fixed Inline Receptacle with Basket weave Cable Grip (Potting Required)

Star-Line EX-17-4 Style

Amphenol Star-Line EX-17-4 Fixed Inline Receptacle

| Connector Dimensions | |||||||

| Shell | A* | B* | C | D | E | F | G |

| 12 | 6-1/4 (159) | 1-7/16 (37) | 1-1/2 (38) | 1-1/4 (32) | 15/16 (24) | 1-9/32 (33) | 8 (203) |

| 16 | 8-1/4 (210) | 2 (51) | 1-7/16 (37) | 1-25/32 (45) | 10-1/2 (267) | ||

| 20 | 2-1/2 (64) | 1-15/16 (49) | 2-9/32 (58) | 14-1/2 (368) | |||

| 24 | 3 (76) | 2-7/16 (62) | 2-25/32 (71) | 17-1/2 (445) | |||

| 28 | 3-1/2 (89) | 2-7/8 (73) | 3-9/32 (83) | 19 (483) | |||

*Notes: For “C” length inserts, add 1/2” to both dimensions “A” & “B”.

Amphenol Hazardous Area Connectors

Amphenol Hazardous Area Connectors | Amphe-Ex | Amphe-Coal EX | EX309 | Rig-Power | Star-Line EX | Amphe-Mine EX

EXPLOSION PROOF & HAZARDOUS AREA ELECTRICAL EQUIPMENT

Integrity | Knowledge | Reliability | Electrical HVAC Process Instrumentation Equipment

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are leaders in the development and distribution of ATEX & IECEx Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Panels | Plugs | Isolators | Enclosures | Lighting | Control Stations | Motor Starters | Call Points | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Fans | Security Locks

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery