Industrial Plugs & Sockets | Amphenol Star-Line Compact Connectors

Amphenol Star-Line Connectors

Industrial Connectors

Amphenol Star-Line | Plugs & Sockets For Harsh Environments

Amphenol Star-Line Series “ZP/ZR” connectors are heavy duty, environmentally sealed plugs and sockets which are already successfully used in all types of Industrial and Aerospace applications.

These compact environmental connectors have provided outstanding performance in petrochemical, geophysical, complex ground support cable networks, process control systems and instrumentation systems.

The materials used and the design features incorporated in Star-Line connectors were originally selected to satisfy the stringent requirements of the Aerospace industry for heavy-duty connectors. These connectors combine electrical and mechanical capabilities that equal or exceed the performance parameters established by the Military Specification MIL-5015.

Amphenol Star-Line

Features

Hard Anodic Coating – All machined aluminium parts finished with a hard, scratch-resistant coating per MIL-A-8625, Type III. Dielectric strength 1800 volts. Heat resistance of 750° F

Reversible Inserts – A full range of contact inserts for power, signal and mixed applications are available. All are interchangeable and reversible to suit specific needs.

Easily Accessible Wire Terminals – Conductors are readily terminated to contacts. Cable housings are slipped over conductors or leads after terminating. Cumbersome handling and seating of inserts with conductors attached is eliminated.

Large Wiring Space – Ample wiring space is provided in cable housings and conduit fitting bodies. Hub of body mounts in any of four positions (except FS & FD box assemblies).

High Tensile Strength Aluminium – Bar Stock Components precision machined. Points of impact designed for extra strength.

Cable Options – Star-Line EX Series can be terminated onto unarmoured or armoured and sheathed cables built to IEEE-45 / UL1309, IEC, BS, DIN and JIC standards. Flexible cables like SOOW-A, W, G-GC and DLO constructions can also be used with these connectors.

Insert Variety – A broad range of inserts are offered ranging from single-contact to 143 contacts. High amperage up to 1135 amps at 1000V / AC or DC. Contacts are high quality copper with silver plating. (Gold plating available as an option) Composite inserts for power, control and instrumentation service available.

RADSOK® High Amperage Contacts – Special arrangements are available with RADSOK high amperage contacts. Standard Star-Line inserts are not interchangeable with new RADSOK contact insert arrangements.

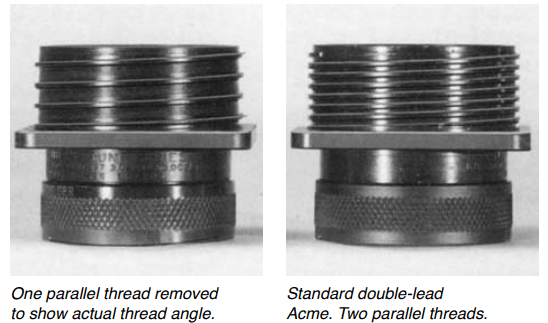

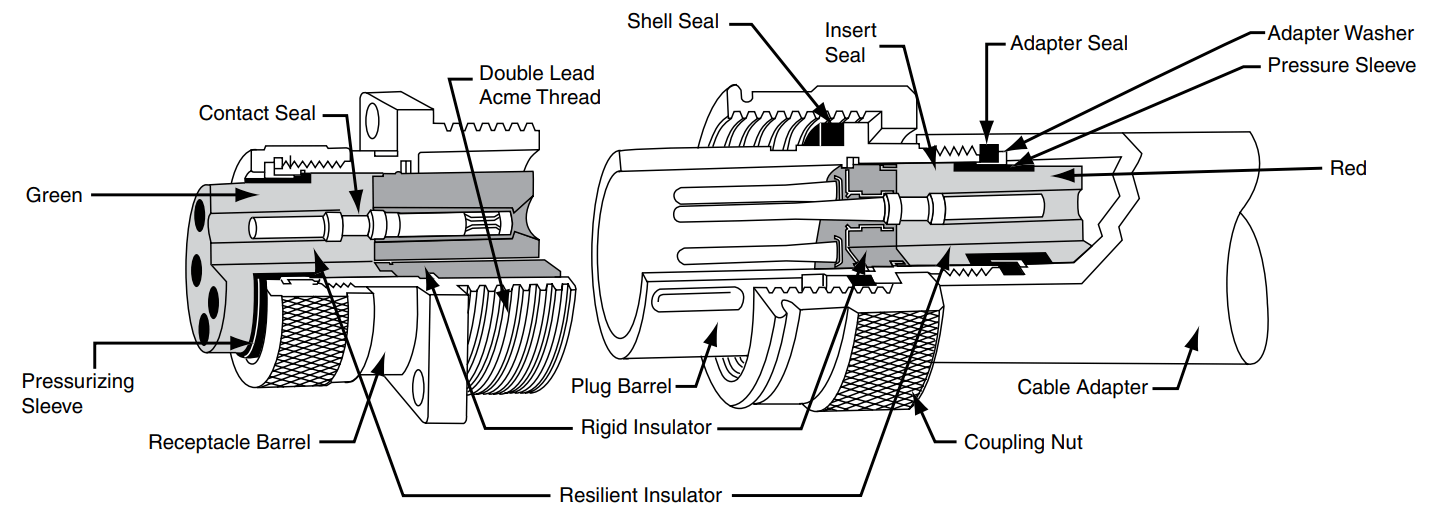

Double-Lead Thread Coupling – Modified Acme Thread does not clog under adverse conditions of ice, snow, sand or mud and provides the quick coupling feature. The double-lead Acme thread is a moderate torque quick-coupling thread which permits complete coupling in approximately one turn of the coupling nut. In addition, there are actually two parallel threads having starting points 180 degrees apart. All of this ensures that plugs and receptacles are being mated or un-mated axially. The thread contour makes it self-cleaning.

UL & CSA listed to UL1977/CSA C22.2 requirements.

Environmental Resistance – Design and materials withstand the most challenging operating conditions. Amphenol Star-Line connectors have an Ingress Protection Rating of IP68-8.

RoHS Compliant Product Available – Contact Thorne & Derrick International.

➡ ATEX versions also available in Amphenol Star-Line EX range.

Amphenol Connectors For Industrial & Harsh Environments | Amphe-309 | Star-Line | Amphe-Lite | GT | 5015 | Amphe-SP3

Amphenol Star-Line Connectors

MOD I – Captive Contact Inserts

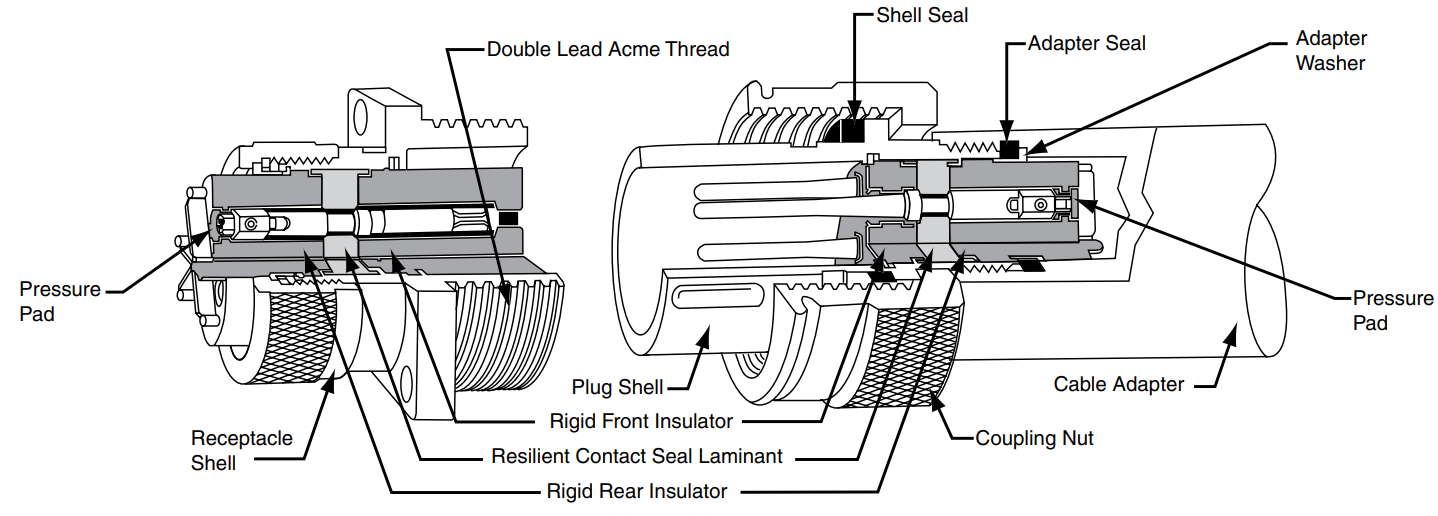

All MOD I captive contact inserts are capable of being terminated after assembly in the basic barrel and are completely self-sealing when pressurised by any selected adaptor.

Water, gas, vapour, moisture or dust cannot pass in either direction through or around the insulation.

The “sandwich” construction of MOD I inserts consists of a resilient silicone laminate between two rigid plastic insulators. The resilient laminate seals absorbs shock and vibration and allows the contacts to align themselves freely. The rigid faced plastic insulators impart just the right amount of restraint to retain the contacts in place.

The combined “sandwich” provides all the advantages of resilient mounting plus all the advantages of rigid mounting, without the drawbacks of either.

Under pressure, between a shoulder and a thrust washer, the silicone reacts as a fluid and being non-compressible, flows against all surfaces to produce a reliable seal around the periphery of the insert and all contacts where they penetrate the insulation.

Contact cavities are clearly numbered on both the front and rear insert face to allow for identification during assembly, inspection and maintenance. Socket insulator contact cavities are of a bell-mouth guided entry design. The chamfered lead-ins insure easy and positive mating of male contacts.

Amphenol Star-Line MOD I Captive Contact Inserts

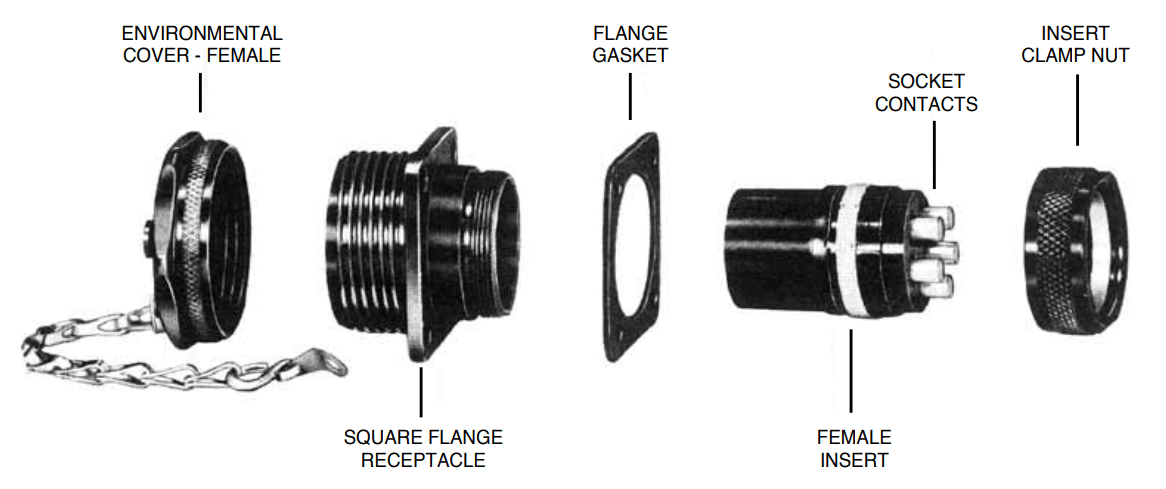

Typical MOD I Receptacle Components | Amphenol Star-Line Connectors

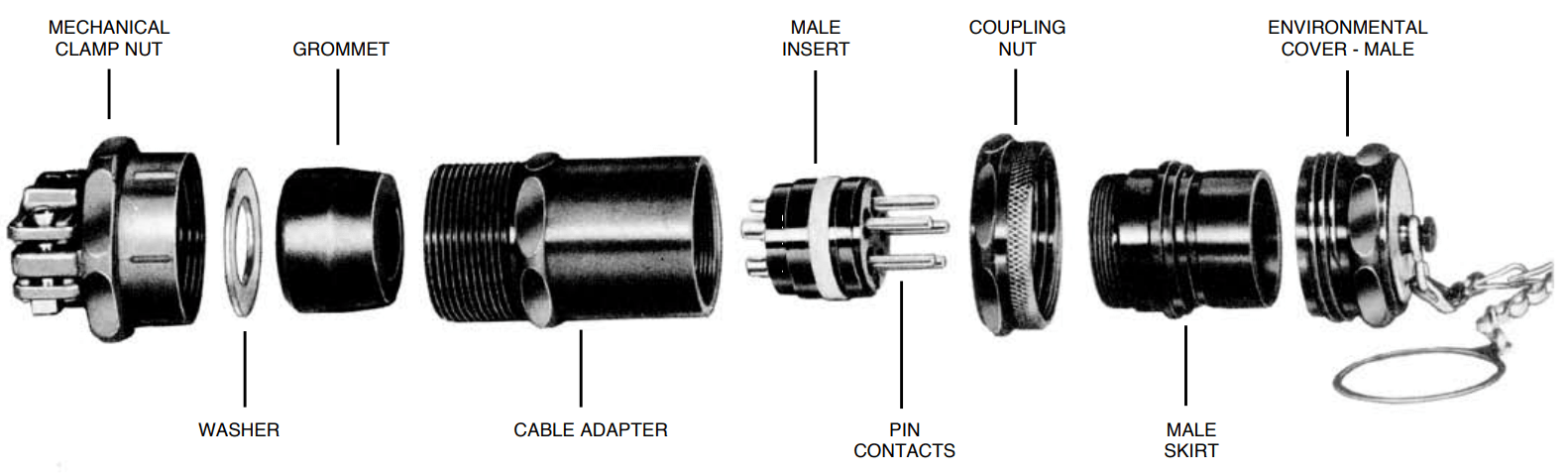

Typical MOD I Plug Components | Amphenol Star-Line Connectors

MOD II – Removable Crimp Contact Inserts

MOD II insulation have one less rigid disc than their MOD I counterparts.

Individual unmounted contacts are crimped to their respective wires outside the connector where ample working space is available. The crimping operation can be by hand or power operated cable crimping tools. Contacts with the crimped joint intact are inserted one by one, with a hand tool, into the insulation pre-mounted within the connector barrel shell.

The resilient portion of the insert seals around the contacts to prevent leakage through the contact cavities, seal against leakage between the insert and shell, absorb shock and vibration, provide electrical insulation between contacts and retain the contacts in the connector.

Contacts may be inserted and removed without compromising the retention or environmental capability.

The front rigid portion of the insert functions to stabilise and ensure positive alignment of the contacts. Contact cavities are clearly numbered on the front and rear insert face to facilitate identification during assembling, inspection and maintenance.

Socket insulator contact cavities are of a bell-mouth guided entry design. These chamfered lead-ins ensure easy and positive mating of male contacts.

Amphenol Star-Line MOD II Removable Crimp Contact Inserts

Custom Built Amphenol Connectors

It is also possible to custom build your own connectors,there are a wide selection of pin insert, plug, receptacle and socket insert configurations available – Contact T&D for more information.

- Power Connectors – 20-30-60-100-200-325-700 Amperes, 1 thru 10 Contacts

- Control & Instrumentation Connectors – 3 thru 143 Contacts

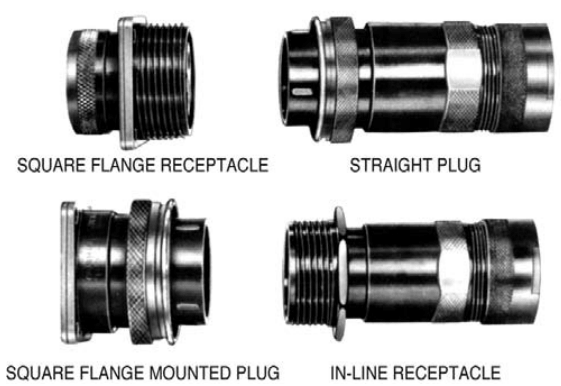

Amphenol Star-Line Connectors | Typical Assemblies

Amphenol Star-Line Connectors Range

The Star-Line connectors range, manufactured by Amphenol, is made up of the following connector types, all of which are suitable for use in industrial and harsh environments:

Straight Plugs

- Straight Plug with Standard Compression Nut – available in shell size 12 thru to C28 to suit cable diameters from 0.062 to 0.125 up to 2.750 to 2.875.

- Straight Plug with Mechanical Clamp Nut – available in shell size 12 thru to C28 to suit cable diameters from 0.062 to 0.125 up to 2.750 to 2.875.

- Straight Plug with Conduit Adaptor (for flexible conduit fittings) – available in shell size 12 thru to C28 to suit conduit sizes between ¾ and 2½.

- Straight Male Plug Panel Mount – available in shell size 12 thru to C28.

- Straight Plug with Basket-weave Cable Grip – available in shell size 12 thru to C28 to suit cable diameters from 0.062 to 0.125 up to 2.750 to 2.875.

In-Line Receptacles

- In-Line Receptacle with Mechanical Clamp Nut – available in shell size 12 thru to C28 to suit cable diameters from 0.062 to 0.125 up to 2.750 to 2.875.

- In-Line Receptacle with Standard Compression Nut – available in shell size 12 thru to C28 to suit cable diameters from 0.062 to 0.125 up to 2.750 to 2.875.

- In-Line Receptacle with Basket-weave Cable Grip – available in shell size 12 thru to C28 to suit cable diameters from 0.062 to 0.125 up to 2.750 to 2.875.

- In-Line Receptacle with conduit adaptor (for flexible conduit fittings) – available in shell size 12 thru to C28 to suit conduit sizes between ¾ and 2½.

Square Flange Receptacles

- Square Flange Receptacle – available in shell size 12 thru to C28.

- Square Flange Receptacle with Mechanical Clamp Nut – available in shell size 12 thru to C28 to suit cable diameters from 0.062 to 0.125 up to 2.750 to 2.875.

- Square Flange Receptacle with Basket-weave Cable Grip – available in shell size 12 thru to C28 to suit cable diameters from 0.062 to 0.125 up to 2.750 to 2.875.

Receptacle Mounted to Junction Box

- Receptacle Mounted to Junction Box with Angle Adaptor – available in shell size 12 thru to C28 with hub sizes between ¾ and 3.

- Receptacle Mounted to Junction Box with Straight Adaptor – available in shell size 12 thru to C28 with hub sizes between ¾ and 3.

How to Order Amphenol Star-Line EX

The range is comprised of seven body (forms) sizes, each with a number of pin/socket size combinations between 1 and 143 contacts. The connector shell size, pin configuration and rating are reflected in the individual type designations.

➡ Call our expert sales team for advice and assistance.

Amphenol Hazardous Area Connectors | Amphe-Ex | Amphe-Coal EX | EX309 | Rig-Power | Star-Line EX | Amphe-Mine EX

EXPLOSION PROOF & HAZARDOUS AREA ELECTRICAL EQUIPMENT

Integrity | Knowledge | Reliability | Electrical HVAC Process Instrumentation Equipment

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are leaders in the development and distribution of ATEX & IECEx Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Panels | Plugs | Isolators | Enclosures | Lighting | Control Stations | Motor Starters | Call Points | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Fans | Security Locks

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery