ASCO Solenoid Valves – Composite Valves To Suit 3/8” & 1” Pipe Sizes

Published 24 Jan 2017

ASCO Valves

ASCO Solenoid Valves 212 Series

By Chris Dodds : estimated reading time 3 minutes

ASCO have developed the 212 series of solenoid valves to include 3/8” and 1” pipe sizes.

This ASCO solenoid valve range is specifically designed for use in commercial and industrial applications, such as in conditioning systems and water purification.

The ASCO 212 series of solenoid valves has the highest pressure (up to 150 psi) and highest temperature ratings (180°F) on the valve market.

The ASCO 212 solenoid valve series has NSF International Certification accredited by the Standard Council of Canada and ANSI: NSF 61 for

drinking water, NSF 169 (special purpose food equipment and devices) and NSF 372 (lead-free).

ASCO 212 solenoid valves are designed to meet the criteria for section 1417 of the Safe Drinking Water Act (SDWA).

ASCO Solenoid Valves 212 Series

Applications

The 212 series of ASCO solenoid valves are ideal for the following applications:

- Food & Beverage – enables money to be saved and offers enhanced taste

- Humidification – reduces scaling and dusting

- Boilers – more energy efficient

- Restaurants – improves steamer operations

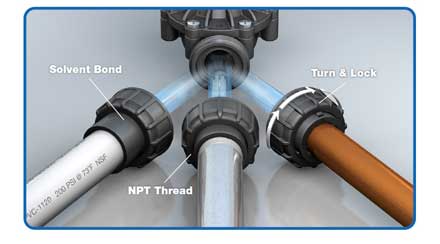

ASCO series 212 composite solenoid valves utilise the FasN Connection System providing reliable and secure connections.

- Easy to install

- Labour saving solenoid valve installation

- Ability to vary connection types on a single valve

- Solenoid valves compatible with copper, PEX and PVC pipe

ASCO Solenoid Valves 212

T&D are an Approved Distributor and Stockist for ASCO valves including the 212 composite valve series as well as other ranges of solenoid valves for safe and hazardous areas – this includes spool valves and operators.

ASCO 212 Series Composite Solenoid Valves

ASCO introduces the new 212 series composite valve – the 212 series composite valve is designed for use in water purification and water treatment applications, specifically within the membrane based filtration system application. The new ASCO 212 series composite valve is ideal for use in mid-size Reverse Osmosis Systems applications where lead free and NSF approved constructions are required. The ASCO 212 series composite valves are available in 3/8″, 1/2″, 3/4″, and 1″ pipe sizes.

ASCO 212 Composite Solenoid Valve

What Is Reverse Osmosis?

Reverse Osmosis is a water filtration process in which dissolved inorganic solids (such as salts) are removed from a solution (such as water) – this is accomplished by household water pressure pushing the tap water through a semi-permeable membrane.

Reverse Osmosis Flow Chart

Contact Us now for a quick quotation or click on request a quote and a member of our technical sales team will respond as soon as possible.

ASCO Solenoid Valves

ASCO Numatics, the world’s leading manufacturer of comprehensive fluid automation, flow control, and pneumatics solutions, has introduced the 212 Series of composite solenoid valves that incorporate the new FasN™ universal connection system. ASCO 212 Series valves have been designed specifically for water purification and conditioning systems in commercial and industrial applications.

ASCO Valve is the worldwide leader in high quality solenoid valves.

ASCO products are utilized on a wide array of applications to control the flow of air, gas, water, oil and steam.

Further ASCO Reading

ATEX Solenoid Valves – ASCO Valves for International Hazardous Area Installations

ASCO Valves – Selecting & Ordering The Correct Valve

Invitation – network, engage, promote

Thorne & Derrick are inviting you to join LinkedIn’s fastest growing Discussion Group – Process & Hazardous Area Industries : Heat Tracing, Gas Detection, Fluid Control & Flow Measurement. News, projects, videos, promotions, whitepapers, jobs, webinars, press plus much more.

THORNE & DERRICK

Electrical & Process Instrumentation Equipment for Explosive Atmospheres

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

We supply major UK and international infrastructure projects and also MRO (Maintenance, Repair, Operations) requirements for both planned and unplanned plant shutdowns – we react with a rapid response to customer demand to ensure downtime is minimised and reliable Power, Light & Heat is restored or provided.

Working closely with clients and our supply chain we can assess the condition and degradation of your hazardous area installations and implement specifications to manage the planned replacement of legacy equipment conformant with international classifications including ATEX and IECEx.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

➡ Also Process Instrumentation Products: Ashcroft Pressure Gauges | ASCO Valves | Katronic Flow Meters | KROHNE Flow Meters | VEGA Level Sensors | Rotronic Temperature & Humidity Sensors | SIKA Pressure Gauges

Further Reading

-

ASCO 212 Solenoid Valve – Product Data Sheet

Size: 1.60 MB

ASCO 212 Solenoid Valve – Product Data Sheet

Size: 1.60 MB