Crude Oil Distillation Processes

Published 10 Jul 2019

VEGA Temperature Measurement, Level Measurement And Process Monitoring In The Petrochemical Industry

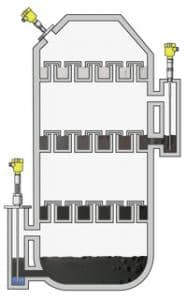

Crude oil is decomposed into individual distillation products and is heated up to 400°C and fed into distillation columns. Pressure monitoring in the column and level measurement in the extraction vessels both occur but the most important controlled variable is temperature measurement for regulating distillation.

VEGAFLEX 67 – Level And Interface Measurement In One Sensor

In the distillation column, it is not uncommon for water to appear under the mineral oil product. It often accumulates in the lower area of the reference vessel and must be pumped out from time to time so that it doesn’t pollute the distillate. VEGAFLEX 67 is mounted on the existing reference vessel (bypass) without any alterations being necessary.

The instrument continuously registers both the total level and the height of the water layer without the bypass having to be completely filled. The process temperature can be up to 400 °C and the pressure up to 400 bar. Neither lateral inlets, welded seams nor buildup or corrosion in the tube have any effect on the guided microwave measurement.

Column Pressure With VEGABAR 61

An important value to monitor in the distillation process is the top pressure at the upper end of the column. Depending on the type of distillation, the systems operate under vacuum or extremely high pressures. The pressure transmitter VEGABAR 61 with its wide temperature range is particularly suited for this application – even extreme temperature fluctuations during the start-up phase in the column do not cause it any problems.

The sensor version with isolator can even be implemented in temperatures up to 400°C.

VEGAFLEX 66 – A Real Alternative To Displacer Measurement

Guided microwave technology is an interesting alternative to displacer systems in the reference vessels of the distillation column. The rod version of VEGAFLEX 66 forms together with the tube of the reference vessel an ideal signal guidance system. Its high functional reliability and availability encompasses everything from the actual detection of levels to the process fitting.

The measurement is independent of temperature, pressure or changes in density of the measured medium. Deposits or welded seams on the wall of the reference vessel or buildup on the rod probe also do not influence the measurement. The process temperature can be up to 400 °C and the pressure up to 400 bar.

Further Reading

Accurate Level Measurement And Pressure Monitoring In The Pharmaceutical Industry

VEGA Level And Pressure Measurement For The Petrochemical Industry

Accurate Level Measurement Of Liquefied Gas

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters

Trace Heating | System Design & Supply

Further Reading

-

VEGA Level Sensor – VEGAFLEX 67 Guided Wave Radar Level Sensor

Size: 143.68 KB

VEGA Level Sensor – VEGAFLEX 67 Guided Wave Radar Level Sensor

Size: 143.68 KB

-

VEGA Level Sensor – VEGAFLEX 66 Guided Wave Radar Level Sensor – Specification

Size: 143.67 KB

VEGA Level Sensor – VEGAFLEX 66 Guided Wave Radar Level Sensor – Specification

Size: 143.67 KB