Heat Tracing Cables For Sugar Silos | Preventing Condensation To Keep Sugar In Free-Flowing Condition

Published 20 Apr 2021

Preventing Condensation To Keep Sugar In Free-Flowing Condition

Heat Tracing Cables By Eltherm

Frost Protection For Industrial & Hazardous Areas

In the sixth of this blog series by Eltherm they will discuss the best electrical trace heating system that will ensure temperature maintenance in sugar silo. Below discusses the engineering, design, installation and commissioning of the complete electrical trace heating solution for a white sugar silo.

The quality of the stored product may be substantially affected by condensation. To prevent this and to keep the sugar in free-flowing condition, it is essential to heat the silo in order to maintain a constant temperature. An increasing number of refineries are turning to high-tech solutions with electrical heat tracing to achieve this.

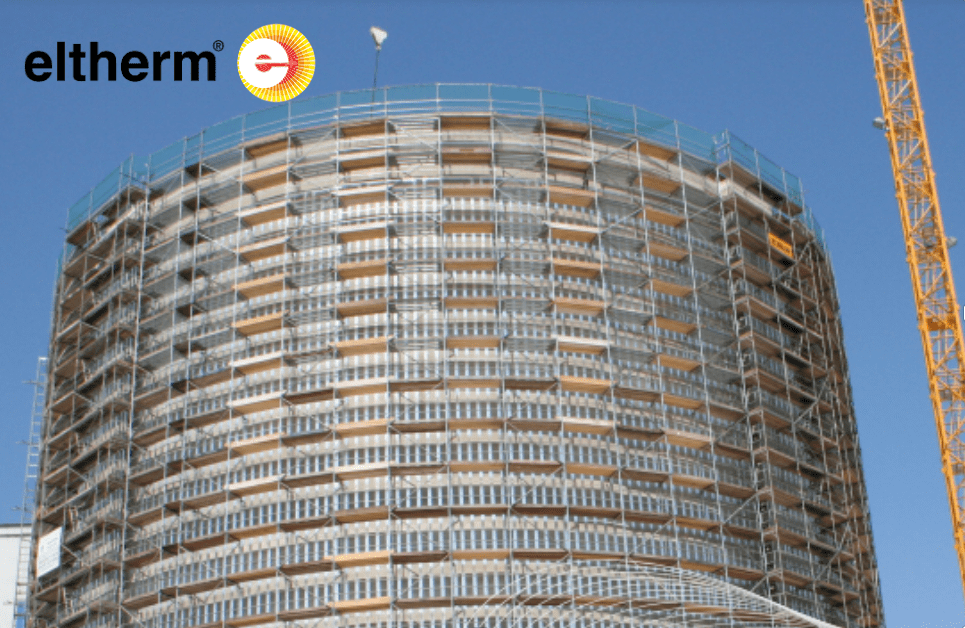

A project that demonstrate Eltherm’s engineering and production expertise for complex projects is the electrical heated jacket for a Pfeifer & Langen silo in Jülich, Germany. The silo has a capacity of 60 000 tons, and an overall height of nearly 80 meters.

Prevent condensation to keep sugar in free-flowing condition

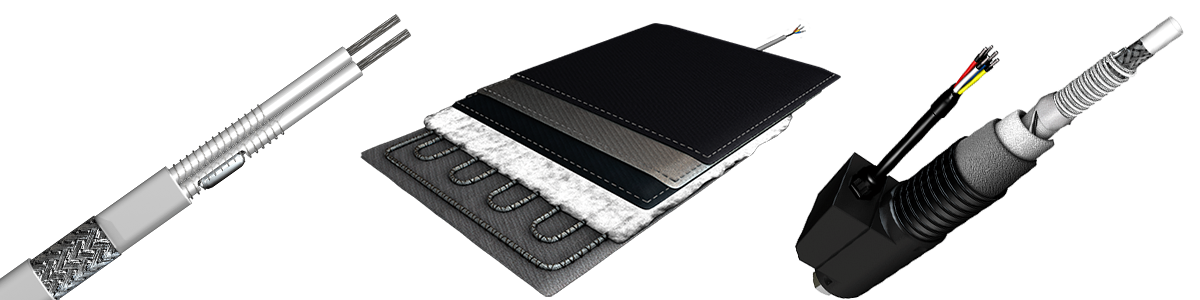

The Eltherm products used for this project:

- Special trace heaters – Self regulating cables ELSR, Constant wattage cables ELKM

- Cold cable

- Connection technology

- Power control panels

- On-site commissioning

Nordzucker sugar silo in Nykøbing (Denmark)

Nordzucker in Nykøbing (Denmark) committed Eltherm for the engineering, design, installation and commissioning of the complete electrical trace heating solution for a white sugar silo. Heating requirements were calculated and the electrical heating system designed accordingly. All in all, the silo was completed as a turnkey project ready for operation, in the record time of just three weeks!

Sugar silo in Jülich, Germany

eltherm heats sugar silos in the Near East

Eltherm engineers provided heating systems for two further sugar silos in the Middle East. The silos are almost 40 meters tall, with a diameter of 40 meters and a capacity of 40 000 tons. An elaborate heating cable construction several kilometres long on the outside walls and specially adapted controls ensure the maintenance of a constant temperature, so that there is no condensation to affect the quality of the stored sugar.

Thorne & Derrick specialise in providing specialist heating for industrial and hazardous areas including Eltherm’s heat tracing cables and heated hoses.

ELTHERM INDUSTRIAL & HAZARDOUS AREA HEATING

Eltherm heating products provide freeze protection, temperature maintenance and temperature control ranges of up to 1000°C and are used in many industries and applications from oil and gas to utilities and power generation. Eltherm products are manufactured to the highest hazardous area specifications including ATEX and IECEx for heating pipes, hoses, drums, vessels and IBC’s.

Eltherm self regulating heat trace cable provides frost protection and maintains product viscosity in pipes, tanks, drums and vessels

Electrical Heating Specialists

Thorne & Derrick International, based in the UK, can specify and supply from stock an extensive range of Electrical Heating Equipment for industrial and process heating applications – this includes temperature maintenance and frost protection (Winterisation) products for pipework, valves, IBC’s, drums, hoses, tanks and vessels. We produce custom silicone heaters for rapid and high temperature heat-up of complex shapes and surfaces – from concept, design to the delivery of standard or bespoke heaters on the shortest lead times. From the largest UK heat tracing cable stocks we deliver Electric Trace Heating Systems for pipework frost protection, ramp heating, roof/gutter snow melting and de-icing – enquire about our in-house design service.

EXPERTS IN WINTERISATION SOLUTIONS FOR INDUSTRIAL & HAZARDOUS AREA ENVIRONMENTS

Thorne & Derrick hold the largest UK stocks of frost protection & winterisation equipment to help keep your plant and personnel operational during the winter months.

Thorne & Derrick understand that prolonged periods of low ambient temperatures can bring operations to a standstill costing thousands of pounds in lost downtime.

Experts in heating solutions for use in industrial & explosive atmospheres, Thorne & Derrick have the knowledge & expertise to help clients prevent unnecessary down time this winter.

We can provide overnight delivery of Trace Heating Cables at the most competitive prices to guarantee frost protection of your pipelines and mechanical services.| Ask About Our Heat Trace Design Service.

💡 Contact us today and our skilled and friendly team can provide technical support as well as reliable, fit for purpose and compliant solutions to suit your exact requirements.

Trace Heating | Process Heating | Heating Jackets | Drum & IBC Heaters | Heated Hoses |Silicone Heating Mats

➡See our Winterisation blog TOP PICKS, including our most read articles about Trace Heating and the requirement for electrical heating products and systems to combat and mitigate Winter weather effects.

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery