SICK GM901 Gas Analyser – Carbon Monoxide (CO) Gas Measurement & Emissions Monitoring

SICK GM901 In-Situ Gas Analyser

In-Situ Gas Analysers

SICK GM901

The SICK GM901 in-situ gas analyser provides efficient process analysis, detection and measurement of carbon monoxide (CO) gas. It is available as either a cross-duct or probe type version. making SICK GM901 gas analysers well suited for difficult carbon monoxide (CO) gas measuring tasks such as high pressure, critical flow profiles, or high measuring gas concentrations.

GM901 in-situ gas analysers are ideal for applications such as; the optimisation of all kinds of combustion processes or biomass combustion plants, CO monitoring in coal mills, process monitoring in the food industry, control of small boiler facilities, and during roasting processes.

Gas Measurement Using SICK GM901 Gas Analyser – CO Carbon Monoxide Applications

SICK GM901 Gas Analyser – Features

- Representative measurement along the duct diameter

- Operation via evaluation unit

- Short response times

- Verifiable with gas-filled cell; gas-testable probe with test gas

- Measurement results in real time due to in-situ measurement

- Fast and simple installation and commissioning

- Easy, user-friendly operation

- Economical due to low maintenance

➡ Did you know? T&D also distribute SICK level sensors, flow sensors, pressure sensors and temperature sensors.

SICK GM901 Gas Analyser

SICK GM901

Technical SPECIFICATION

GM901 Gas Analyser cross-duct system

| Description | Cross-duct version in-situ gas analyser |

| Measured Values | CO |

| Measurement Principles | Gas filter correlation |

| Measuring Distance | 0.5 m … 8 m |

| Measuring Ranges | CO: 0 … + 500 ppm / 0 … 20,000 ppm (Relative to 1m measuring path) |

| Response Time (t90) | 5 s … 360 s |

| Accuracy | ± 5 % of measuring range full scale |

| Process Temperature | ≤ +250 °C or with extended calibration: ≤ +430 °C |

| Process Pressure | ≤ 30 hPa (depending on purge air supply) |

| Process Gas Humidity | Non-condensing |

| Ambient Temperature | –20 °C … +55 °C |

| Conformities | TUEV type-examination |

| Electrical Safety | CE |

| Enclosure Rating | IP65 |

| Mounting | Mounting flange, DN125, PN6 Mounting flange, ANSI, 5″ |

| Power Supply | Voltage: 115 V/230 V Frequency: 50 Hz/60 Hz Power consumption: ≤ 75 W |

| Test Functions | Manual span check with gas-filled cell |

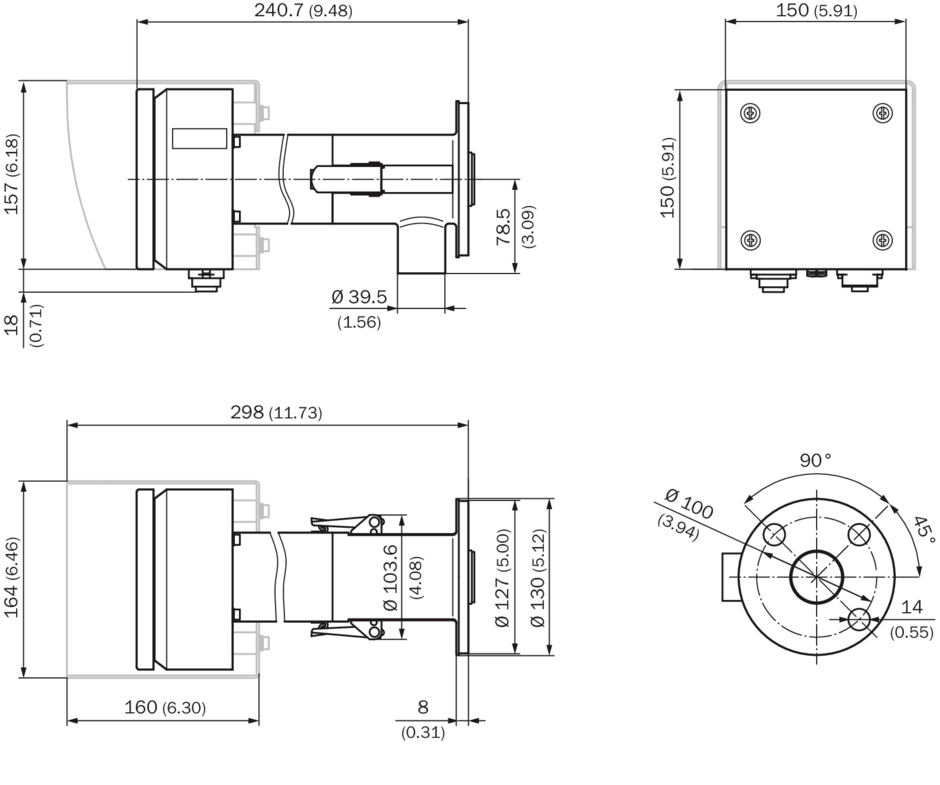

| Sender Unit | |

| Description | Sender unit of the cross-duct measuring system |

| Electrical Safety | CE |

| Dimensions (W x H x D) | 150 mm x 169 mm x 240 mm |

| Weight | 3 kg (including purge air fixture) |

| Receiver Unit | |

| Description | Receiver unit of the cross-duct measuring system |

| Electrical Safety | CE |

| Dimensions (W x H x D) | 150 mm x 169 mm x 404 mm |

| Weight | 3 kg (including purge air fixture) |

SICK GM901 Sender & Receiver Unit

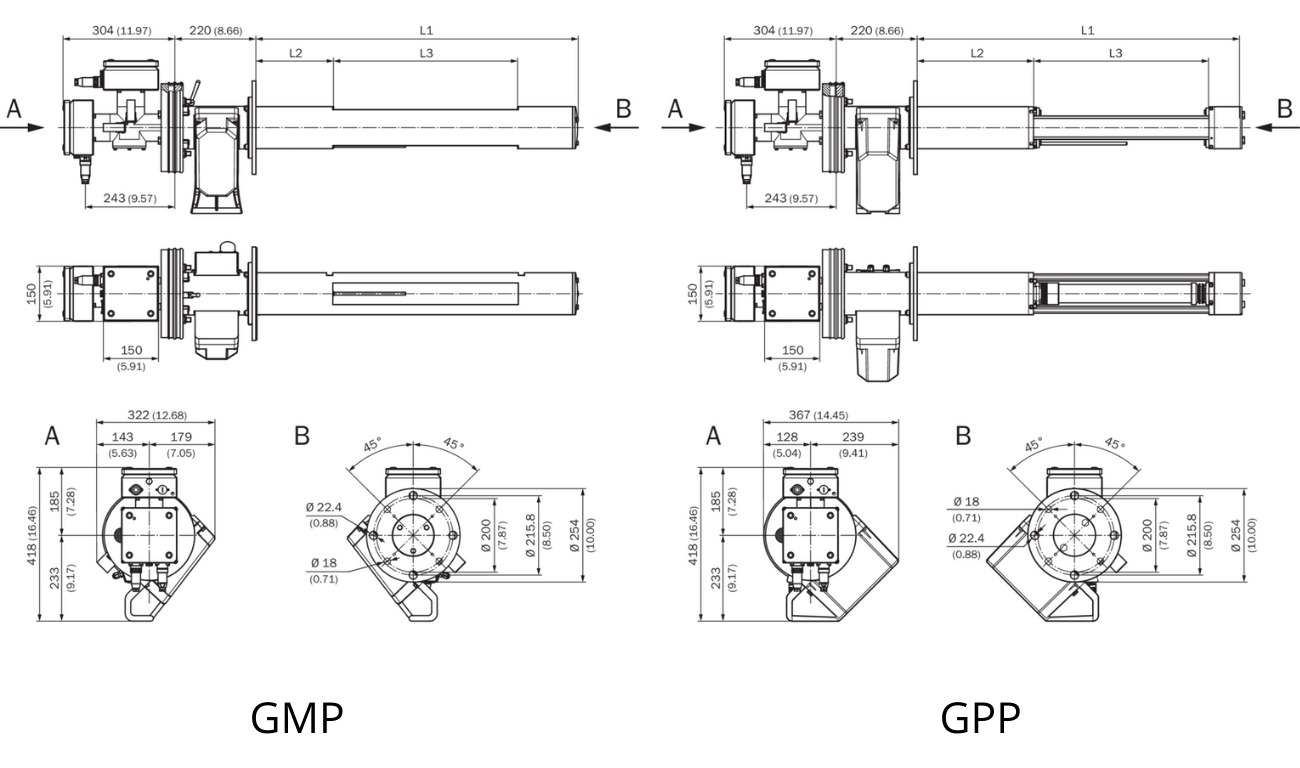

sick GM901 Measuring probe system

| Description | Measuring probe version in-situ gas analyser |

| Measured values | CO |

| Measurement Principles | Gas filter correlation |

| Measuring Ranges | CO: 0 … 250 ppm / 0 … 10,000 ppm (Relative to 1m measuring path) |

| Response Time (t90) | 5 s … 360 s |

| Accuracy | ± 5 % of measuring range full scale |

| Process Temperature | Open measuring probe (GMP): ≤ +250 °C With extended calibration: ≤ +430 °C Gas-testable measuring probe (GPP): ≤ +220 °C |

| Process Pressure | ≤ 120 hPa |

| Process Gas Humidity | Non-condensing |

| Ambient Temperature | –20 °C … +55 °C |

| Conformities | TUEV type-examination U.S. EPA conform |

| Electrical Safety | CE |

| Enclosure Rating | IP65/NEMA 4 |

| Dimensions (W x H x D) | 367 mm x 418 mm x 1,414 mm |

| Mounting | Single mounting point on the duct Mounting flange, DN125, PN6 Mounting flange, ANSI, 5″ |

| Power Supply | Voltage: 115 V/230 V Frequency: 50 Hz/60 Hz Power consumption: ≤ 60 W |

| Test Functions | Manual span check with gas-filled cell |

SICK GM901 Sender/Receiver Unit with gas-testable measuring probe (GPP) & with open measuring probe (GMP)

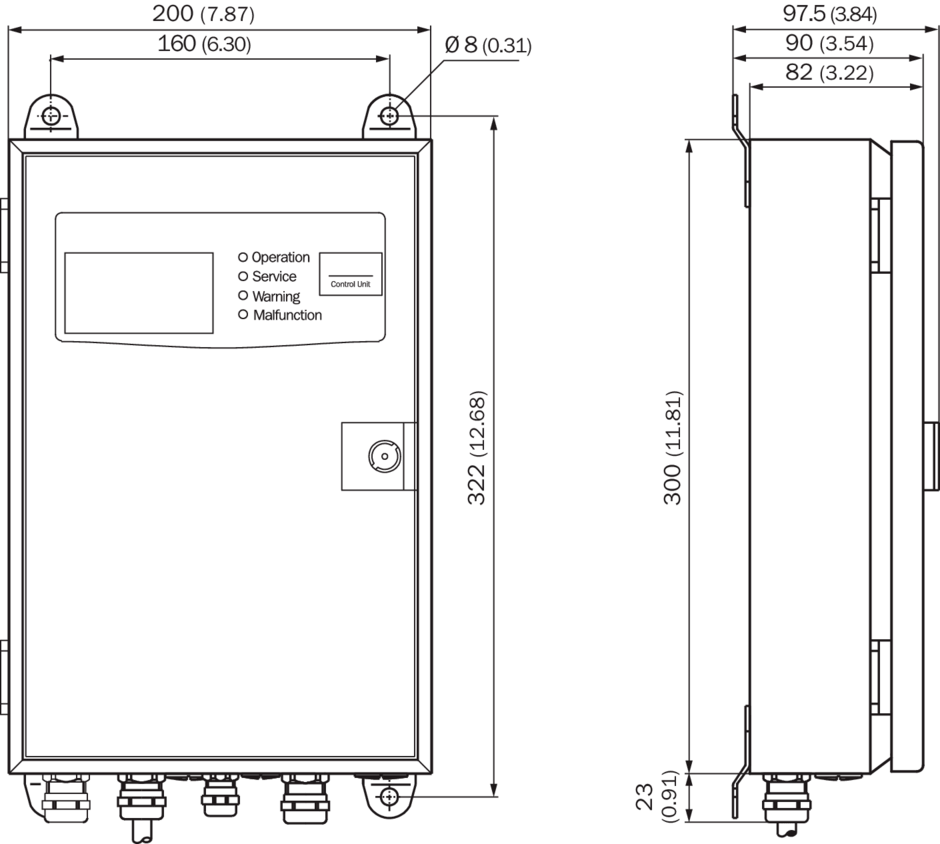

GM901 control unit – sheet steel housing

| Description | The control unit serves as the human machine interface and is responsible for data processing and output as well as control and monitoring functions. |

| Electrical Safety | CE |

| Enclosure Rating | IP65/NEMA 4x |

| Analog Outputs | 1 output: 0/4 … 20 mA, + 500 Ω Electrically isolated |

| Analog Inputs | 1 input: 0 … 20 mA, 100 Ω |

| Digital Outputs | 2 relay contacts: + 150 V AC, 1 A, 60 W / 125 V DC, 1 A, 30 W |

| Digital Inputs | 1 input: + 5 V, 2 mA |

| Communication Interface | Serial PROFIBUS DP CAN bus Type of fieldbus integration: RS-232/RS-485 Function: Proprietary service interface/Internal system bus |

| Number | 1 |

| Indication | LC display Status LEDs: “Operation”, “Service”, “Warning” and “Malfunction” |

| Input | Arrow keys & Functional keys |

| Model | Steel sheet enclosure |

| Dimensions (W x H x D) | 200 mm x 346 mm x 97.5 mm |

| Weight | 4.3 kg |

| Power Supply | Voltage: 115 V/230 V Frequency: 50 Hz/60 Hz Power consumption: ≤ 50 W |

GM901 Control Unit (Steel Sheet Enclosure)

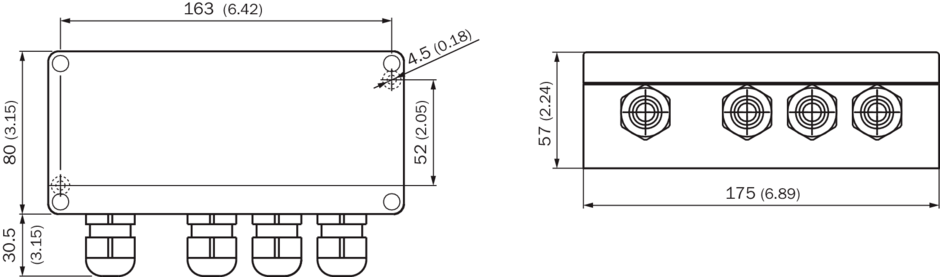

SICK GM901 Connection unit

| Description | For extending the internal CAN bus connection with a cable provided by the customer |

| Electrical Safety | CE |

| Dimensions (W x H x D) | 175 mm x 110.5 mm x 175 mm |

| Weight | 3 kg |

| Power Supply | Voltage: 115V/230V Frequency: 50Hz/60 Hz |

| Integrated Components | On-board 24V power supply for the sender/receiver unit |

GM901 Connection Unit | In-Situ Gas Analysers

SLV4-2 Purge Air Unit, 2BH1300, 3-ph

| Description | Unit to provide dust-free air for flushing of optical surfaces |

| Gas Flow Rate | 38 m³/h … 63 m³/h At 30 hPa counter pressure, depending on low pressure inside the filter |

| Ambient Temperature | –40 °C … +55 °C |

| Electrical Safety | CE |

| Enclosure Rating | IP54 |

| Dimensions (W x H x D) | 550 mm x 550 mm x 258 mm |

| Weight | 18 kg |

| Power Supply – Three-Phase Current | Δ: 200 … 240 V, 50 Hz, 2,6 A, 400 W Y: 345 … 415 V, 50 Hz, 1,5 A, 400 W Δ: 200 … 275 V, 60 Hz, 2,6 A, 500 W Y: 380 … 480 V, 60 Hz, 1,5 A, 500 W Δ: 270 … 330 V, 50 Hz, 2,0 A, 400 W Y: 465 … 570 V, 50 Hz, 1,16 A, 400 W Δ: 290 … 360 V, 60 Hz, 2,1 A, 500 W Y: 500 … 600 V, 60 Hz, 1,26 A, 500 W Δ: 230 V, 50 Hz, 2,7 A, 370 W Δ: 115 V, 60 Hz, 3,0 A, 450 W Δ: 220 … 270 V, 50 Hz, 2,5 A, 400 W Y: 380 … 465 V, 50 Hz, 1,45 A, 400 W Δ: 240 … 290 V, 60 Hz, 2,6 A, 500 W Y: 415 … 500 V, 60 Hz, 1,55 A, 500 W |

| Auxiliary Gas Connections – Purge Air | Hose nozzle 40 mm |

| Test Functions | Pressure switch (switching point –35 hPa) |

| Integrated Components | 2-step air filter, type Europiclon, dust capacity 200 g |

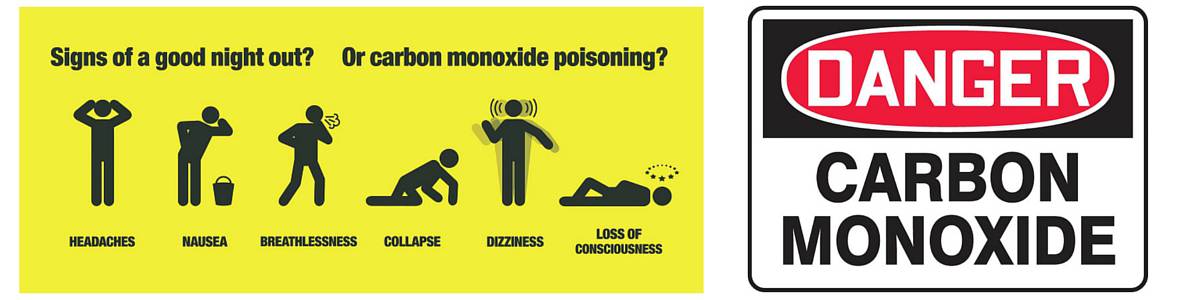

The Dangers of Carbon Monoxide Gas

Gas, Liquid & Bulk Solids Sensors, Analysers & Detectors from SICK

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES & Hazardous Areas

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters