SICK GMS800 FIDOR | Extractive Gas Analysers For Hydrocarbon Measurements

Extractive Gas Analysers

SICK GMS800 FIDOR

Gas analysis for continuous hydrocarbon measurements

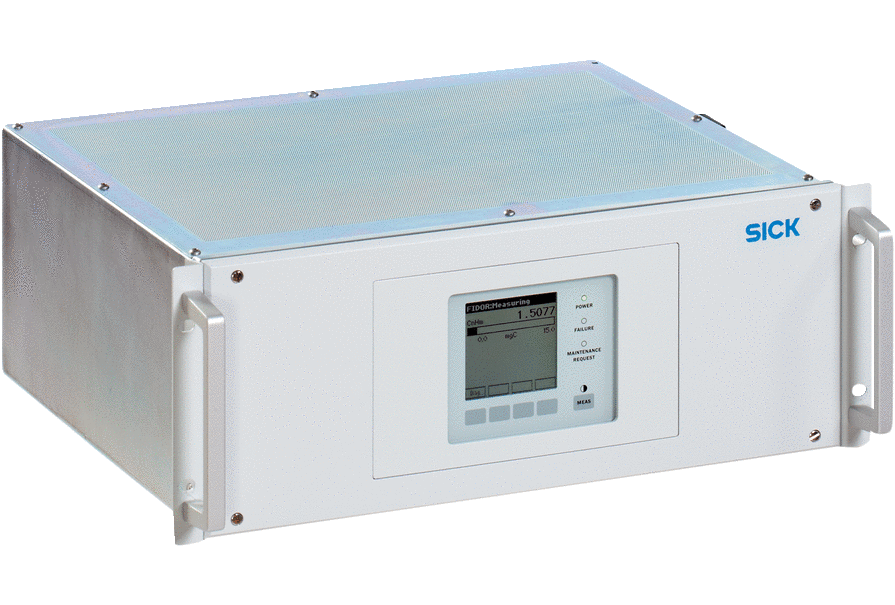

The GMS800 FIDOR is an extractive gas analyser manufactured by SICK, it is a member of the GMS800 analyser family. The GMS800 FIDOR extractive gas analyser is ideally suited to emission monitoring applications in waste incinerators or cement and power plants, for example.

Based on the proven flame ionization detection principle, the GMS800 FIDOR measures total hydrocarbon concentrations in gases at both trace and high concentration levels.

The SICK GMS800 FIDOR is available in three versions:

- GMS810 FIDOR with integrated control unit (BCU),

- GMS811 FIDOR with separate control unit (BCU),

- GMS840 FIDOR with a space-saving wall housing which makes integration into existing systems such as SICK’s MCS100 E HW multi-component analyser very easy.

➡ T&D stock Process Instrumentation for industrial processes, explosive atmospheres & hazardous areas.

Pressure Gauges | Solenoid Valves | Flowmeters | Pressure Transmitters & Sensors | Control Valves | Temperature Sensors

SICK GMS800 FIDOR Gas Analyser

Features

- Standard 19” enclosure for easy integration into all industry-typical systems

- Space-saving wall housing (stand-alone)

- Nearly maintenance free ejector pump delivers sample gas to the analyser

- Integrated catalytic converter (option) provides very clean zero gas

- Automatic regulation and compensation of process pressure fluctuations

- Protective filter at sample gas inlet

- High degree of linearity (≤ 2 %) for very low and high measuring ranges

➡ T&D also distribute the range of SICK In-Situ Gas Analysers

SICK GMS800 FIDOR

Technical SPECIFICATION

Please note: The exact device specifications and performance data of the product may deviate from the information provided here, and depend on the application in which the product is being used and the relevant customer specifications.

GMS800 FIDOR System

| Measured Values | Corg |

| Performance Tested Measurands | Corg |

| Gas Flow Rate | ≤ 120 l/h |

| Process Temperature | ≤ +230 °C |

| Process Pressure | –120 hPa … 120 hPa Relative |

| Process Gas Humidity | Non-condensing |

| Ambient Temperature | +5 °C … +40 °C |

| Storage Temperature | –20 °C … +70 °C |

| Ambient Pressure | 900 hPa … 1,100 hPa |

| Ambient Humidity | ≤ 95 % Non-condensing |

| Conformities | Approved for plants requiring approval – 2001/80/EC (13. BImSchV) 2000/76/EC (17. BImSchV) 27. BImSchV TA-Luft (Prevention of Air Pollution) EN 15267 EN 14181 MCERTS |

| Electrical Safety | CE |

| Power Supply | Power consumption: Without external heating |

| Auxiliaries | Instrument air: ≤ 1,000 l/h Instrument air: 4.5 ±0.5 bar Fuel gas: Typ. 30 ml/min Hydrogen: 5.0 or higher; 3 ±0.2 bar Combustion air: Typ. 250 ml/min Instrument air: 3 ±0.2 bar; measuring ranges below 300 ppm (500 mg/m³) require an internal or external catalytic converter Zero gas: ≤ 500 l/h Instrument air: 3 ±0.2 bar; measuring ranges below 300 ppm (500 mg/m³) require an internal or external catalytic converter Reference gas: ≤ 500 l/h Propane in synthetic air: 75% of measuring range full scale value Purge gas: > 1,200 l/h Air for case flushing, inlet |

| Corrective Functions | Adjustment with test gases |

| Test Functions | Extended device diagnosis via SOPAS ET software |

GMS810 Design

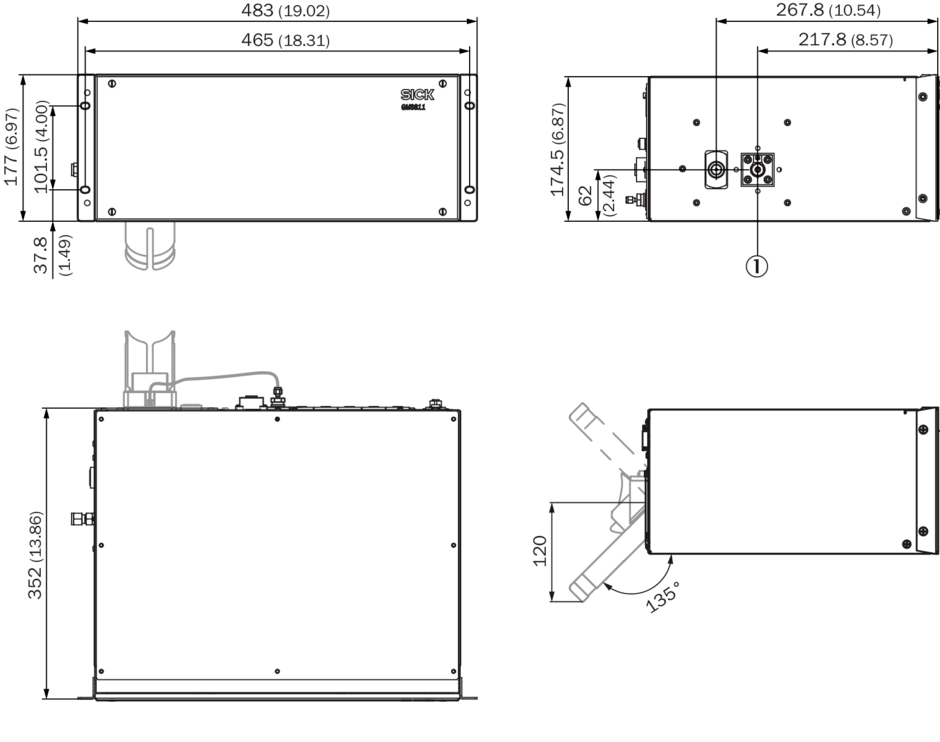

| Description | 19″ rack enclosure with 4 rack units, for integration in cabinets |

| Electrical Safety | CE |

| Enclosure Rating | IP40 |

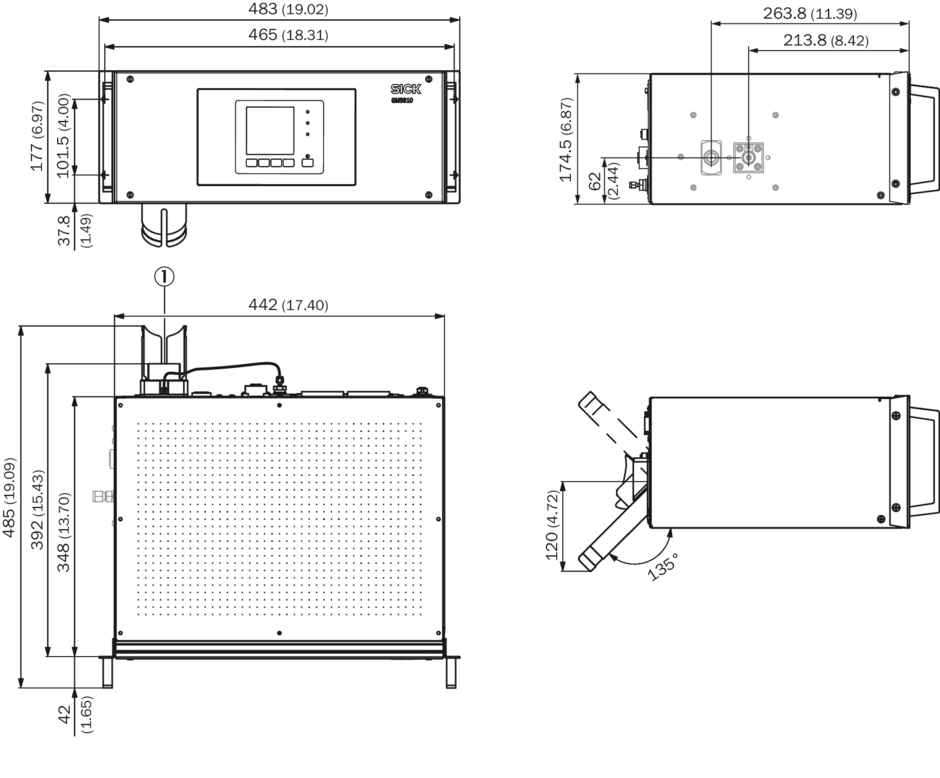

| Dimensions (W x H x D) | 483 mm x 177 mm x 485 mm |

| Weight | ≤ 17 kg |

| Power Supply | Voltage: 90 … 240V Frequency: 47 … 63Hz Power consumption: ≤ 450 W |

| Sample Gas Connections | Sample gas inlet: G 1/4″; G 1/8″ double, without antikink; G 1/8″ without antikink Exhaust gas outlet: 12 mm straight; 1/2″ straight; 10 mm 90° bent |

| Auxiliary Gas Connections | Auxiliary gas inlet: Varies depending on type |

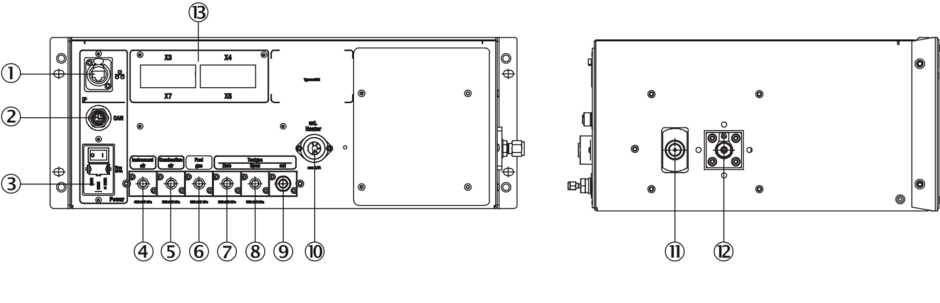

SICK GMS810 FIDOR | ① On the GMS810 FIDOR, the sample gas inlet can be located on the rear or on the side (shown in light grey).

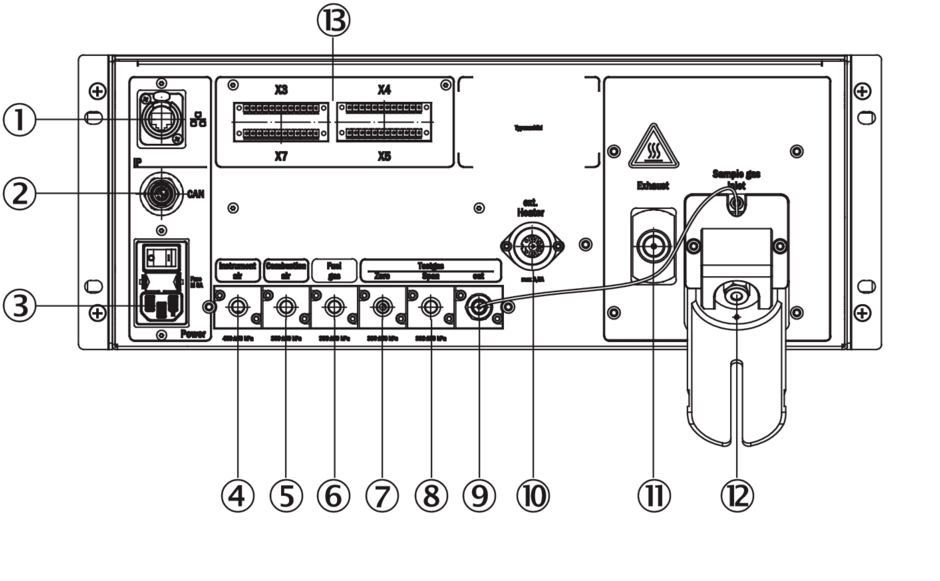

GMS810 FIDOR and GMS811 FIDOR: Sample gas inlet on the back

① Ethernet, ② CAN, ③ line connection, ④ instrument air, ⑤ combustion air, ⑥ fuel gas, ⑦ zero gas, ⑧ reference gas, ⑨ test gas outlet, ⑩ external heating, ⑪ exhaust gas outlet, ⑫ sample gas inlet, ⑬ I/O module

GMS810 FIDOR and GMS811 FIDOR: Sample gas inlet on the side ① Ethernet ② CAN ③ line connection ④ instrument air ⑤ combustion air ⑥ fuel gas ⑦ zero gas ⑧ reference gas ⑨ test gas outlet ⑩ external heating ⑪ exhaust gas outlet ⑫ sample gas inlet ⑬ I/O module

GMS811 Design

| Description | 19″ rack enclosure with 4 rack units, for usage with separate control unit (BCU), for integration in cabinets |

| Electrical Safety | CE |

| Enclosure Rating | IP40 |

| Dimensions (W x H x D) | 483 mm x 177 mm x 352 mm |

| Weight | ≤ 17 kg |

| Power Supply | Voltage: 90 … 240V Frequency: 47 … 63Hz Power consumption: ≤ 450 W |

| Sample Gas Connections | Sample gas inlet: G 1/4″; G 1/8″ double, without antikink; G 1/8″ without antikink Exhaust gas outlet: 12 mm straight; 1/2″ straight; 10 mm 90° bent |

| Auxiliary Gas Connections | Auxiliary gas inlet: Varies depending on type |

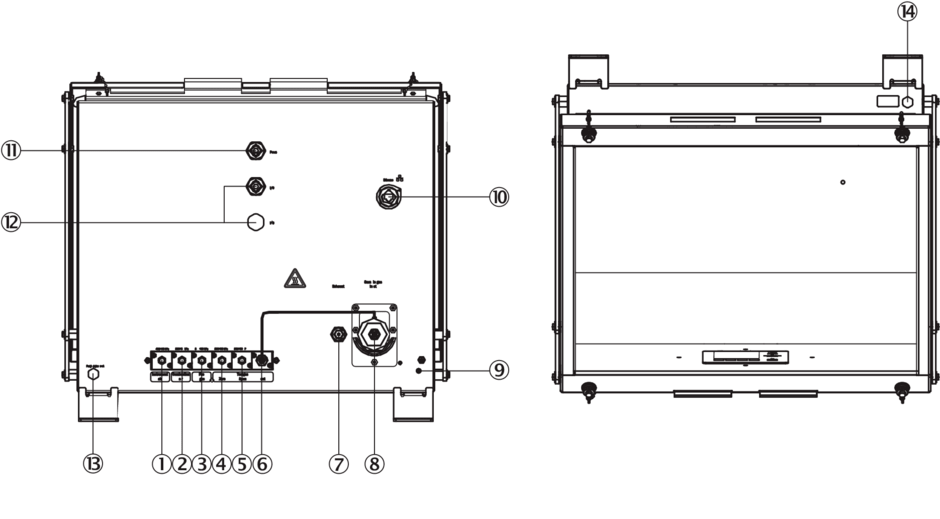

SICK GMS811 FIDOR

GMS840 Design

| Description | Closed sheet steel housing for wall mounting for use indoors |

| Electrical Safety | CE |

| Enclosure Rating | IP54 |

| Dimensions (W x H x D) | 522 mm x 475 mm x 478 mm |

| Weight | 20 kg |

| Power Supply | Voltage: 100 … 120 V / 220 … 240 V Frequency: 50 … 60Hz Power consumption: ≤ 300 W |

| Sample Gas Connections | Sample gas inlet: Straight screw-in connection, 6 mm, G1/8″, stainless steel Exhaust gas outlet: G 1/4″ |

| Auxiliary Gas Connections | Depending on type |

SICK GMS840 FIDOR

FIDOR analyser module

| Description | Flame ionization detector for measuring volatile organic components (VOC) |

| Measured Values | Corg |

| Performance-Tested Measurands | Corg |

| Measurement Principles | Flame ionisation detection |

| Gas Flow Rate | ≤ 120 l/h |

| Measuring Ranges | Corg: 0 … 15 mg/m³ / 0 … 10,000 mg/m³ A flame arrester must be provided by the customer when measuring gas concentrations above the lower explosion limit (LEL) |

| Certified Measuring Ranges | Corg: 0 … 15 mg/m³ / 0 … 50 mg/m³ / 0 … 150 mg/m³ / 0 … 500 mg/m³ |

| Response Time (t90) | ≤ 2.5 s Without sample gas line |

| Sensitivity Drift | < 3 %: within the maintenance interval, relative to measuring range full scale |

| Zero Point Drift | < 3 %: within the maintenance interval, relative to measuring range full scale |

| Detection Limit | Corg: 0.05 mg/m³ |

| Electrical Safety | CE |

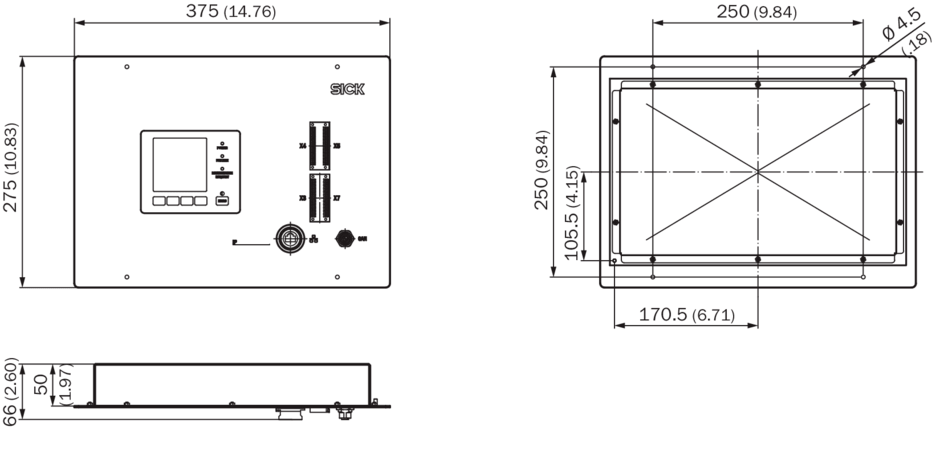

BCU Control Unit

| Description | The control unit serves as the human machine interface and is responsible for data processing and output as well as control and monitoring functions. |

| Indication | Status LEDs: “Power,” “Failure,” and “Maintenance request”, LC Display |

| Operation | Via LC display and membrane keyboard |

| Dimensions (W x H x D) | For separate BCU control unit: 375 mm x 275 mm x 66 mm |

SICK GMS800 FIDOR BCU Control Unit

I/O Module

| Description | Closed module with top-hat rail adapter or module for integration into enclosures |

| Analog Outputs | 4 outputs: 0/2/4 … 20 mA, 500 Ω Electrically isolated |

| Analog Inputs | 2 inputs: 0/2/4 … 20 mA, 500 Ω Not electrically isolated |

| Digital Inputs | 8 inputs: + 42 V All inlets with common reference potential |

| Communication Interface | Modbus, Ethernet Type of fieldbus integration: TCP, RTU RS-485 Function: Connection to SOPAS ET software or OPC server |

| Number | 1 |

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES & Hazardous Areas

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters