SICK MCS300P | Extractive Gas Analysers For Simultaneous Process Monitoring

Extractive Gas Analysers

SICK MCS300P

Simultaneous process monitoring of up to 6 measuring components

The MCS300P is an extractive gas analyser manufactured by SICK which is used for the simultaneous process monitoring of up to six measuring components. It is an extractive process photometer for measuring gaseous or liquid media.

SICK MCS300P measures IR and VIS active components with variable measuring ranges from very low (ppm) to high (vol%) concentrations. For monitoring of toxic or flammable mixtures, it has special process cells with safety devices like twinseals and flushing gas feeds.

The heatable cells made of corrosion-resistant materials have a high pressure resistance.

Automatic adjustment, innovative operation concept and modern communication protocols make the SICK MCS300P an all-purpose photometer, even for potentially explosive atmospheres.

Typical Applications for SICK MCS300P Gas Analysers

- Process monitoring in production of vinyl chloride or isocyanate

- Process control in the chemical industry

- Process monitoring in the production of plastics

- Monitoring of exhaust gas purification plants

- Determination of the water content of solvents

➡ T&D stock Process Instrumentation for industrial processes, explosive atmospheres & hazardous areas.

Pressure Gauges | Solenoid Valves | Flowmeters | Pressure Transmitters & Sensors | Control Valves | Temperature Sensors

SICK MCS300P Gas Analyser

Features

- Simultaneous measurement of up to 6 components

- Process cells up to 60 bar and 200 °C

- Automated sample point switching

- Integrated adjustment unit (optional)

- Safety devices for measurement of toxic or flammable mixtures

- Extended operation via PC and SOPAS ET software

- Flexible I/O module system

- Automatic adjustment without expensive test gases

- Integration into existing networks

- Integration of external parameters like temperature or pressure

- Suitable for explosive environments

- Easy installation and maintenance thanks to transparent, compact design

➡ T&D also distribute the range of SICK In-Situ Gas Analysers

SICK MCS300P

Technical SPECIFICATION

Please note: The exact device specifications and performance data of the product may deviate from the information provided here, and depend on the application in which the product is being used and the relevant customer specifications.

MCS300P System

| Measured Values | Br2, CCl4, C2Cl4, CCl2F2, C3F6, CH4, C2H2, C2H4, C2H6, C3H4, C3H6, C3H8, C4H6, C4H8, C4H10, C6H6, C6H14, C7H8, CH3Cl, CH2Cl2, CHCl3, C2H3Cl, C2H2Cl2, C2H4Cl2, C2HCl3, C6H5Cl, C6H4Cl2, CHCl2F, CH3OH, C3H7OH, C2H4(OH)2, CH3CHO, HCOOH, CH3COOC2H3, C2H2O, Cl2, CO, CO2, COCl2, HCl, HCN, HF, H2O, NH3, NO, N2O, NO2, R-NCO, SO2, SiF4, many other IR / VIS active gases and liquids |

| Measurement Principles | Interference filter correlation, Gas filter correlation |

| Spectral Range | VIS version: 300 nm … 1200 nm IR-version: 1200 nm … 12000 nm |

| Measuring Ranges | More than 60 measuring components available (depending on concentration and sample gas composition) Up to 6 components simultaneously 2 measuring ranges per component Automatic measuring range switching (adjustable) 2 limit values per component Measuring ranges depend on application and combination of measuring components |

| Response Time (t90) | 30 s … 120 s adjustable |

| Zero Point Drift | VIS version: < 1 %: of smallest measuring range per day IR-version: < 2 %: of smallest measuring range per week |

| Detection Limit | < 2 %: relative to measuring range end value |

| Ambient Temperature | +5 °C … +40 °C Temperature change maximum ±10 °C/h |

| Storage Temperature | –20 °C … +60 °C |

| Ambient Humidity | ≤ 80 % Non-condensing |

| Hazardous Area Approvals | IECEx Ex pxb IIC T3…T4 Gb Ex pzc IIC T3…T4 Gc Process cuvette: Ex eb IIC Gb ATEX |

| Electrical Safety | CE |

| Enclosure Rating | IP65: measuring cuvette depending on version |

| Analog Outputs | 2 outputs: 0/4 … 22 mA, + 500 Ω Electrically isolated; max. number of outputs depends on application |

| Analog Inputs | 2 inputs: 0/4 … 22 mA, 100 Ω Electrically isolated; max. number of inputs depends on application |

| Digital Outputs | 5 outputs: 2 power relays, electrically isolated; 3 outputs, potential-free; max. number of outputs depends on application |

| Digital Inputs | 4 inputs: Open contacts, potential-free; max. number of inputs depends on application |

| Communication Interface | Modbus, Ethernet Remark: Not in the Ex version Type of Fieldbus integration: TCP Function: Connection to SOPAS ET software or OPC server |

| Number | 1 |

| Indication | Status LEDs: “Power,” “Failure,” and “Maintenance request”, LC display |

| Input | Functional keys |

| Operation | Via LC-display Via software SOPAS ET (not in the Ex-version) |

| Dimensions (W x H x D) | Dimensions may vary. For details, see the dimensional drawings. |

| Weight | See dimensional drawings |

| Material In Contact With Media | Measuring cuvette depending on version |

| Material | Aluminium, coated |

| Power Supply | Voltage: Standard version: 115 V / 230 V, Ex-version: 230 V, Ex control device: 230 V Frequency: Analyzer: 50 … 60 Hz, Ex control device: 48 … 62 Hz Power consumption: Analyser: ≤ 230 W, With cuvette heating: ≤ 805 W, With 2nd heating: ≤ 1,450 W |

| Corrective Functions | Cross-sensitivity compensation of up to 6 interferents |

extractive gas analysers

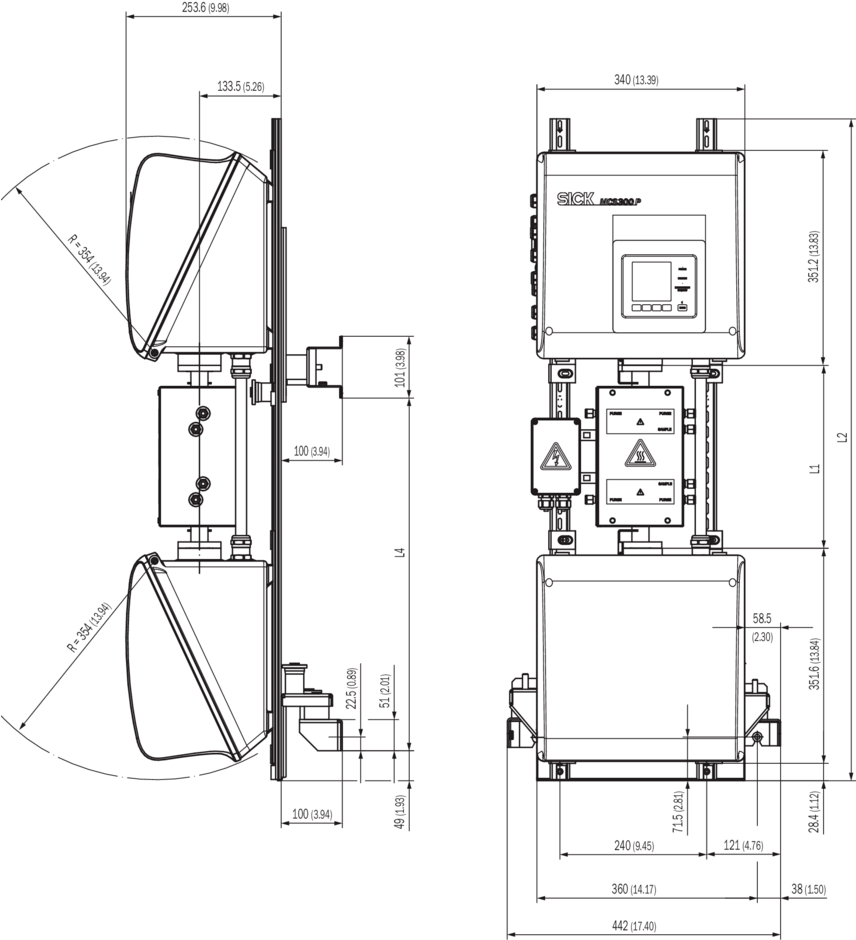

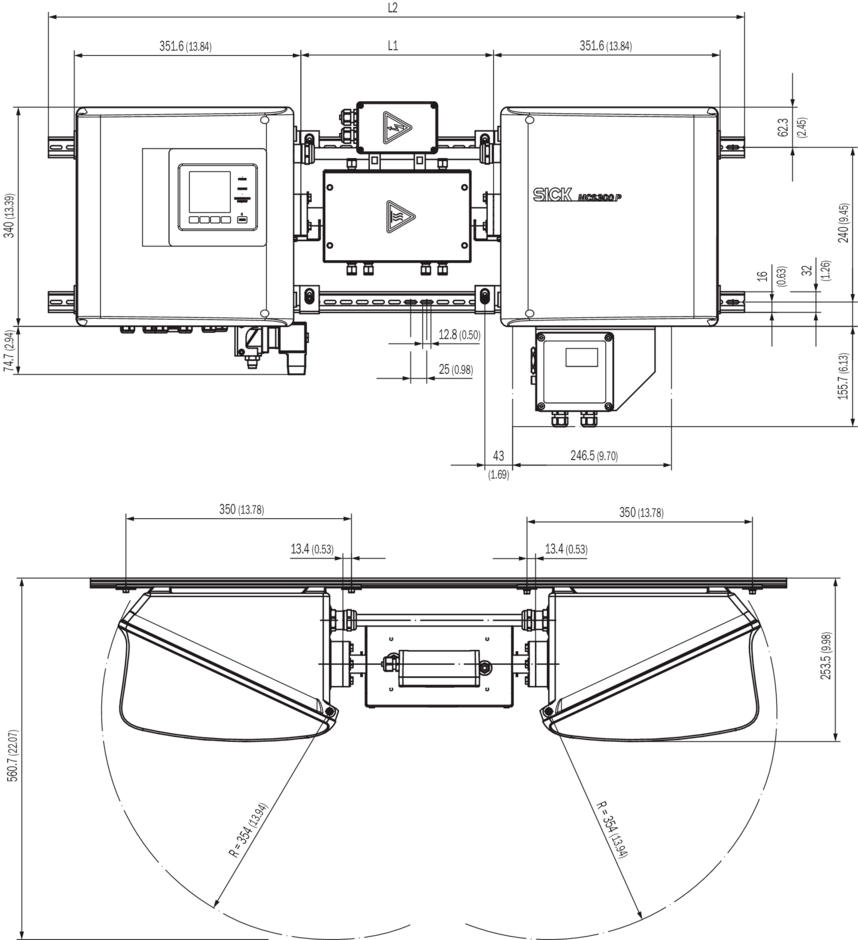

Dimensional Drawings – sick mcs300p – Standard Version

SICK MCS300P Vertical

All dimensions in mm (inch); all weights in kg.

| Cuvette | Length | Weight | ||

| L1 | L2 | L4 | ||

| FGK | 224 (8.82) | 1000 (39.37) | 494 (19.45) | 39.5 |

| PGK190, FGK | 299 (11.77) | 1080 (42.52) | 569 (22.40) | 43 |

| PGK20 | 399 (15.71) | 1180 (46.46) | 669 (26.34) | 45 |

| PGK50 | 699 (27.52) | 1480 (58.27) | 969 (38.15) | 51 |

| PGK75 | 949 (37.36) | 1730 (68.11) | 1219 (47.99) | 56 |

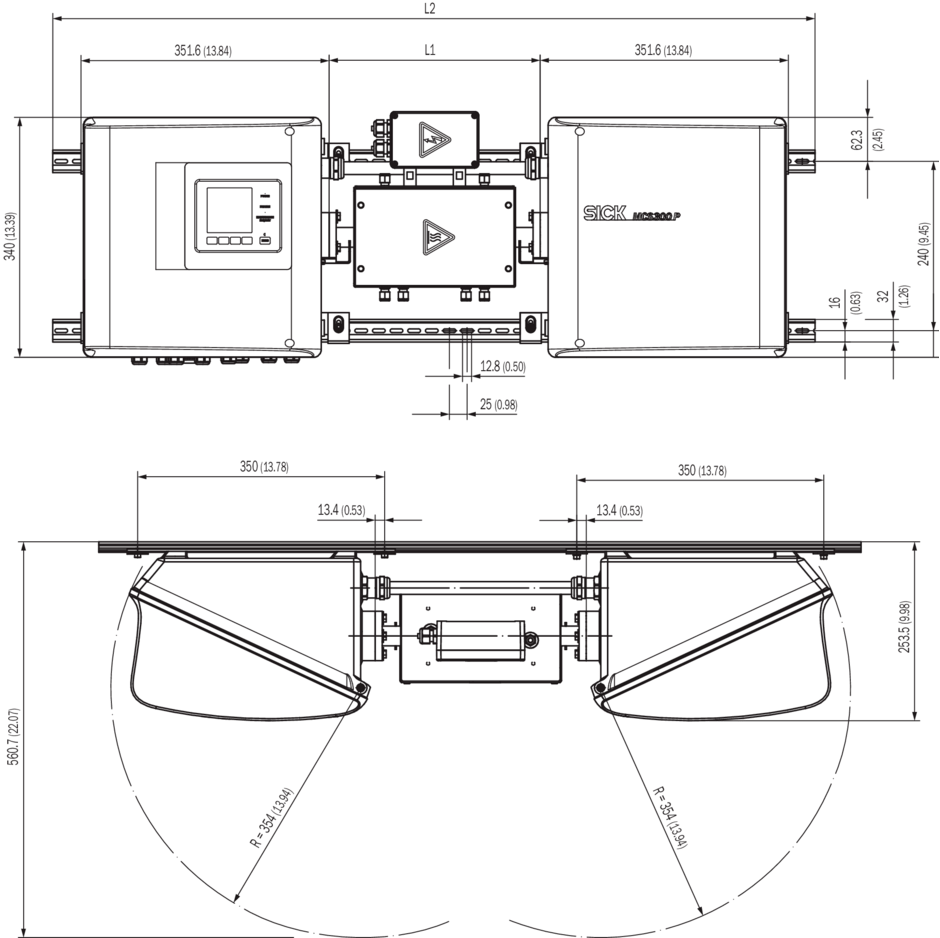

SICK MCS300P Horizontal

All dimensions in mm (inch); all weights in kg.

| Cell | Length | Weight | |

| L1 | L2 | ||

| FGK | 168 … 229 | 1000 | 33.5 |

| PGK190, FGK | 299 | 1080 | 37 |

| PGK20 | 399 | 1180 | 39 |

| PGK50 | 699 | 1480 | 45 |

| PGK75 | 949 | 1730 | 50 |

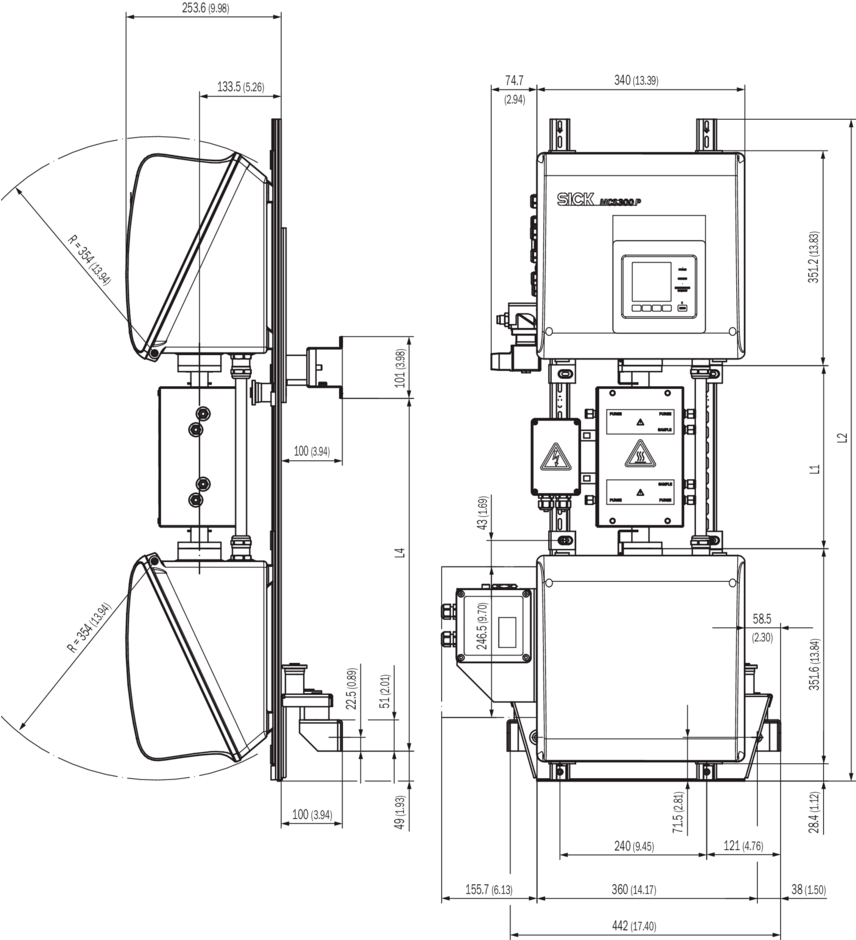

Dimensional Drawings – sick mcs300p – Ex Version

SICK MCS300P Ex – Vertical

All dimensions in mm (inch); all weights in kg.

| Cuvette | Length | Weight | ||

| L1 | L2 | L4 | ||

| PGK10 Ex | 299 (11.77) | 1080 (42.52) | 569 (22.40) | 43 |

| PGK20 Ex | 399 (15.71) | 1180 (46.46) | 669 (26.34) | 45 |

| PGK50 Ex | 699 (27.52) | 1480 (58.27) | 969 (38.15) | 51 |

| PGK75 Ex | 949 (37.36) | 1730 (68.11) | 1219 (47.99) | 56 |

SICK MCS300P Ex Horizontal

All dimensions in mm (inch); all weights in kg.

| Cell | Length | Weight | |

| L1 | L2 | ||

| PGK10 Ex | 299 (11.77) | 1080 (42.52) | 37 |

| PGK20 Ex | 399 (15.71) | 1180 (46.46) | 39 |

| PGK50 Ex | 699 (27.52) | 1480 (58.27) | 45 |

| PGK75 Ex | 949 (37.36) | 1730 (68.11) | 50 |

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES & Hazardous Areas

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters