Hazardous Area Connectors For Mining | Amphenol Amphe-Coal EX

Amphnol Amphe-Coal EX Connectors for Hazardous Areas

Hazardous Area Connectors for Mining

Amphe-Coal EX

ATEX & IECEx Connectors | Underground Mining | Explosion Proof

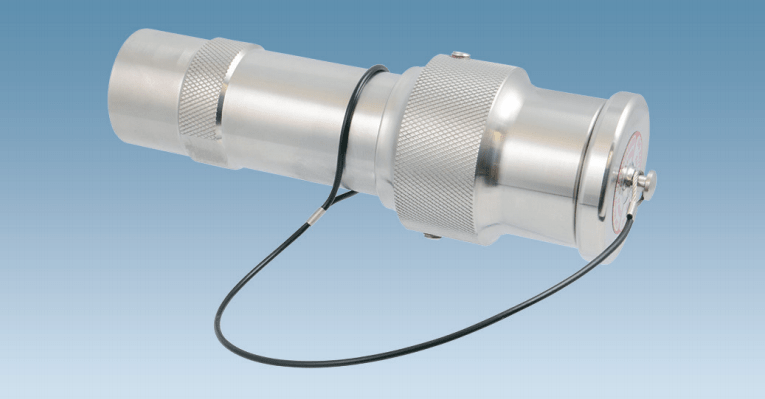

The Amphenol Amphe-Coal EX circular hazardous area connector series is designed, manufactured, and certified to one of the highest mining industry standards: IECEx Group 1.

With the growing need for increased power and signal in a smaller package in underground explosive mining areas, the Amphe-Coal EX connectors are a miniature version of the already well established Amphenol Amphe-Mine EX range. The design of these hazardous area connectors allows the use of smaller wire gauge, down to #26 AWG.

These interconnects are comprised of a stainless steel bodied plug and receptacle to form an in-line cable or cable-to-panel connection. Each plug and receptacle shell is supplied with an ATEX certified cable gland that fits onto the main body of the device.

Internally, the shell of each half contains an insert that houses either solder or crimp type contacts, pin or socket. Numerous hybrid inserts are available which offer a combination of copper and Coax/Twinax.

Amphenol Amphe-Coal EX connectors are ideal for use in underground mining applications such as:

– Batteries

– Motors

– Engines

Hazardous Area Connectors – Features

- Underground mining explosion proof design

- Hazardous area, environmental connector IP68

- Rated up to 217 amps at 1250 V DC I 900 V AC

- Triple-lead threaded coupling system

- With EEx d (Flameproof) Cable Glands

- Vast family of inserts, for power, signal and mixed applications

- 7 different shell sizes: 09, 11, 13, 15, 17, 19, and 21

- Insert configurations ranging from 2 #20 AWG, up to 79 #22D AWG

- Numerous hybrid inserts available that offer a combination of copper and Coax/Twinax.

Hazardous Area Certificates and Technical Data

IECEx Certified for Group 1 Mining. Cert. # ITA 12.0009X

IECEx Certified for Group 2 Cert. # SIR 08.0029X

ATEX Certified for Zone 1-IIc hazardous environment. Cert. # SIRA 07ATEX122

Amphenol Hazardous Area Connectors | Amphe-Ex | Amphe-Coal EX | EX309 | Rig-Power | Star-Line EX | Amphe-Mine EX

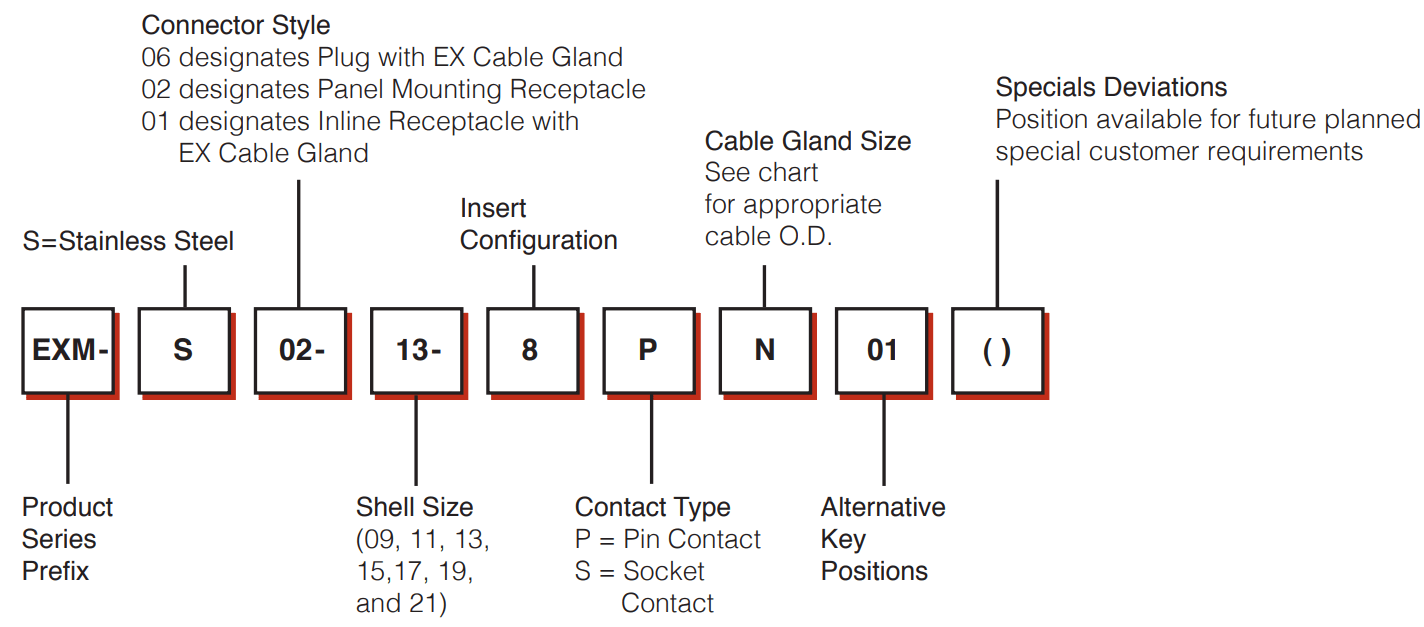

How to Order Amphenol Amphe-Coal EX

Connector Order Code Logic

➡ Call our expert sales team for advice and assistance.

Amphenol Amphe-Coal EX Connectors | How to Order

Rating Tables

| Maximum Voltage | Contact Patterns |

| 500 Vrms | 9-5, 17-22, 21-75 |

| 550 VDC / 400 VAC | 9-35, 9-94, 11-35, 13-35, 15-35, 15-AC, 17-31, 17-35, 19-35, 21-35 |

| 500 VDC / 400 VAC 500 Vrms (8 Co-ax Contacts) 500 Vrms (Twin-ax Contacts) |

17-2, 19-31 |

| 850 VDC / 600 VAC | 9-98, 11-2, 11 -5, 11-98, 11 -99, 13-4, 13-8, 13-13, 13-98, 15-15, 15-18, 15-19, 15-97, 17-6, 17-26, 17-99, 19-32, 21-11, 21-39, 21-41 |

| 1250 VDC / 900 VAC | 15-5, 17-8, 19-11 , 21 -16 |

Current Rating per Shell Size

| Connector Shell Size | Maximum Total Current (A) |

| 9 | 48 |

| 11 | 64 |

| 13 | 90 |

| 15 | 125 |

| 17 | 154 |

| 19 | 191 |

| 21 | 217 |

Current Rating per Pin Size

| Connector Pin Size | Maximum Total Current (A) |

| 22D AWG | 5 |

| 20 AWG | 7.5 |

| 16 AWG | 13 |

| 12 AWG | 16 |

| 12 Co-ax | 1 (for inner and intermediate contacts) 12 (for outer contact) |

| 8 Co-ax | |

| 8 Twin-ax |

Amphenol Connectors For Industrial & Harsh Environments | Amphe-309 | Star-Line | Amphe-Lite | GT | 5015 | Amphe-SP3

EXPLOSION PROOF & HAZARDOUS AREA ELECTRICAL EQUIPMENT

Integrity | Knowledge | Reliability | Electrical HVAC Process Instrumentation Equipment

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

Thorne & Derrick are leaders in the development and distribution of ATEX & IECEx Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Panels | Plugs | Isolators | Enclosures | Lighting | Control Stations | Motor Starters | Call Points | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Fans | Security Locks

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery