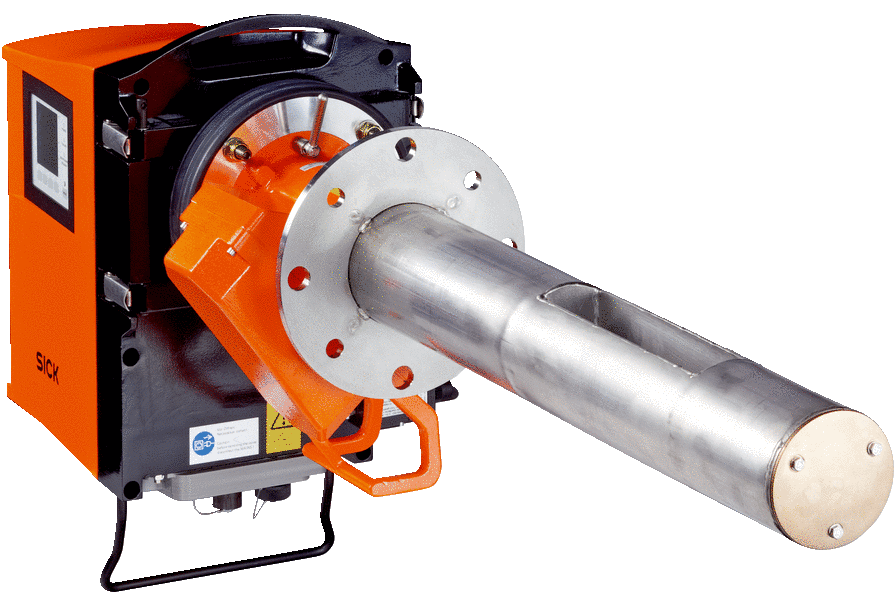

SICK GM32 In-Situ Gas Analyser – ATEX Zone 1 & Zone 2 Hazardous Area Gas Analyser

In-Situ Gas Analysers

SICK GM32

The SICK GM32 in-situ gas analyser is ATEX certified for gas analysis, measurement and monitoring in hazardous areas Zone 1 and Zone 2.

The GM32 in-situ gas analyser measures SO2, NO, NO2 and NH3, as well as TRS components in Kraft pulp processes including pressure and temperature in the gas duct. It is direct, fast and does not require gas sampling or transport – This means control systems are able to work with actual values in real time. Self-monitoring ensures that the measured values are always reliable and in the case of a malfunction, an early warning will be shown.

For emission measurement of SO2 and NO, SICK GM32 is tested for suitability according to European standard EN 15267. An ATEX version (GM32-EX) with comprehensive safety functions and sophisticated system technology is also available, as well as the GM32 TRS-PE (PE = Pulp Emission) for TRS measurement in Kraft pulp processes.

SICK GM32-EX is used for gas analysis, measurement and monitoring in the oil, gas and chemical industry – the ATEX certified gas analyser is available in both cross duct and measuring probe versions.

BS EN 15267 specifies the performance criteria and test procedures for automated measuring systems that measure gases and particulate matter in, and flow of, the waste gas from stationary sources.

SICK GM32 Gas Analyser – Features

- Unaltered measured values in real time without altering the gas composition

- Short-term process deviations are detected

- Representative measurement by selection of cross-duct or measuring probe type

- Fast on-site service due to modular design

- Long maintenance-free intervals

- Cost-effective in-situ gas analyser — ATEX type also available

- Low cost of installation and operation, no test gases required

- Complete emissions measurement in kraft pulp process by way of simultaneous measurement of TRS components plus SO2, NO, NH33

➡ Did you know? T&D also distribute SICK level sensors, flow sensors, pressure sensors and temperature sensors.

SICK GM32

Technical SPECIFICATION

GM32 Gas Analyser System – Standard & Ex-Version

| Description | In-situ gas analyser for emission monitoring and process measurement |

| Measured Values | NO, NO2, NH3, SO2 |

| Performance-Tested Measurands | NO, SO2 |

| Measurement Principles | Differential optical absorption spectroscopy (DOAS) |

| Zero Point Drift | ± 2 %: relative to measuring range end value |

| Reference Point Drift | ± 2 %: within the maintenance interval (6 months), relative to measuring range full scale |

| Ambient Temperature | –20 °C … +55 °C Temperature change maximum ±10 °C/h |

| Storage Temperature | –20 °C … +55 °C |

| Ambient Humidity | ≤ 95 % Relative humidity; non-condensing |

| Conformities | Approved for plants requiring approval 2001/80/EC (13. BImSchV) 2000/76/EC (17. BImSchV) 27. BImSchV TA-Luft (Prevention of Air Pollution) EN 15267 EN 14181 MCERTS GOST |

| Hazardous Area Approvals | |

| IECEx | Ex pzc op is [ia] IIC T3 Gc |

| ATEX | II 3G Ex pzc op is [ia] IIC T3 Gc |

| Electrical Safety | CE |

| Gas Analyser Models | Cross-duct version |

| Measuring probe version | |

| Mounting | Mounting flange, DN125, PN6 |

| Mounting flange, ANSI, 5″ | |

| Test Functions | Internal zero point check Check cycle for zero and span point according to QAL3 |

| Options | SCU control unit (for non-hazardous areas only) Multi range calibration (additional measuring ranges for one component) Extended gas temperature range up to 550 °C or 650 °C LowNO2 |

| Measuring Ranges (Measuring ranges refer to 1 m measuring path & depend on application and device version) |

|

| NH3 | 0 … 30 ppm / 0 … 2,600 ppm |

| NO | 0 … 40 ppm / 0 … 1,900 ppm |

| NO2 | 0 … 50 ppm / 0 … 1,000 ppm |

| Low NO2 | 0 … 20 ppm / 0 … 1,000 ppm |

| SO2 | 0 … 32 ppm / 0 … 7,000 ppm |

| Certified Measuring Ranges With an active measuring path length of 1.86 m (cross- duct), 1.25 m (open path measuring probe) or 1 m (open path measuring probe, LowNO2) The gas-testable measuring probe (GPP) is not TUV approved. |

|

| NO | 0 … 70 mg/m³ / 0 … 700 mg/m³ / 0 … 1,302 mg/m³ |

| SO2 | 0 … 75 mg/m³ / 0 … 1,000 mg/m³ / 0 … 2,500 mg/m³ |

SICK GM32 TRS-PE System

| Description | In-situ gas analyser for TRS monitoring in the Kraft pulping process |

| Measured Values | NO, NH3, SO2, CH3SH, (CH3)2S, (CH3)2S2, H2S, TRS |

| Measurement Principles | Chemometrical data evaluation (CDE) |

| Measuring Ranges Measuring ranges refer to 1 m measuring path, Measuring ranges depend on application and device version, TRS = H2S + CH3SH (as H2S equivalent), For device variant 7: TRS = H2S + CH3SH + (CH3)2S + 2x (CH3)2S2 Other measuring ranges on request |

|

| NH3 | 0 … 35 ppm / 0 … 50 ppm |

| NO | 0 … 40 ppm / 0 … 150 ppm |

| SO2 | 0 … 15 ppm / 0 … 35 ppm |

| H2S | 0 … 35 ppm |

| CH3SH | 0 … 25 ppm |

| (CH3)2S | 0 … 20 ppm |

| (CH3)2S2 | 0 … 15 ppm |

| TRS | 0 … 70 ppm |

| Response Time (t90) – Gas-testable measuring probe (GPP) | ≥ 120 s (Response time adjustable) |

| Accuracy Relative to the smallest measuring range |

|

| NH3 | ± 2 % |

| NO | ± 2 % |

| SO2 | ± 0.3 ppm … ± 2 % |

| H2S | ± 2 % |

| CH3SH | ± 2 % |

| (CH3)2S | ± 2 % |

| (CH3)2S2 | ± 2 % |

| TRS | ± 2 % |

| Ambient Temperature | –20 °C … +55 °C (Temperature change maximum ±10 °C/h) For device variant 7 – +20 °C … +30 °C |

| Ambient Humidity | ≤ 95 % Relative humidity; non-condensing |

| Electrical Safety | CE |

| Mounting | Mounting flange, DN125, PN6 Mounting flange, ANSI, 5″ |

| Test Functions | Internal zero and reference point check |

| Options | SCU control unit |

Hazardous Area Gas Measurement Using SICK GM32 Gas Analyzer Applications

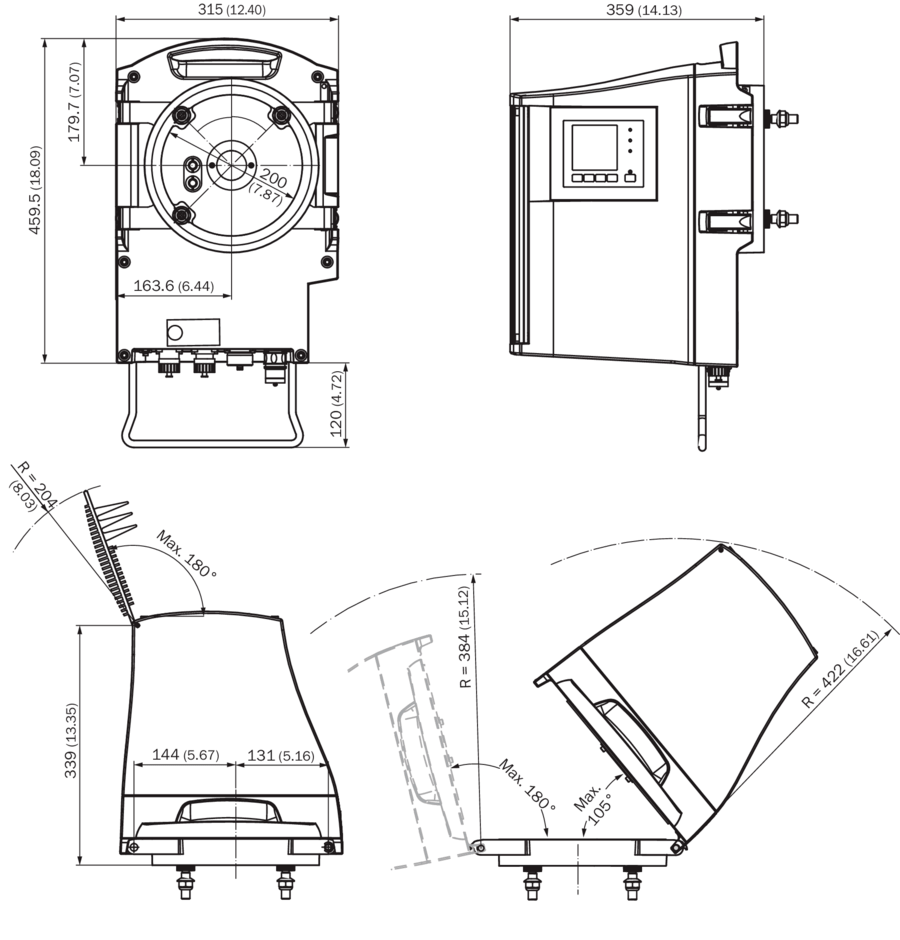

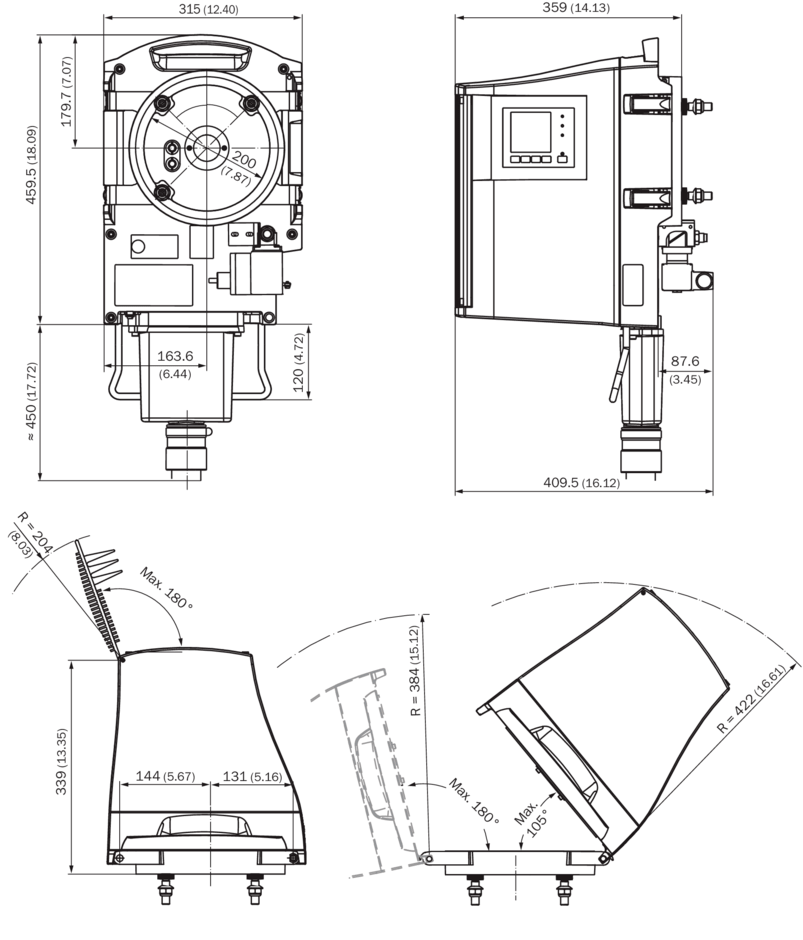

Sender/Receiver Unit

| Description | Analyser unit of the measuring system |

| Electrical Safety | CE |

| Enclosure Rating | IP65 / IP69K |

| Operation | Via integrated control unit |

| Dimensions (W x H x D) | 315 mm x 580 mm x 359 mm |

| Weight | 20 kg |

| Power Supply | |

| Voltage | 24 V DC |

| Supply via connection unit | |

| Power Consumption | 36 W |

SICK GM32 Gas Analyser – Sender/Receiver Unit

Sender/Receiver Unit – EX-Version

| Description | Analyser unit of the measuring system |

| Electrical Safety | CE |

| Enclosure Rating | IP65 / IP69K |

| Operation | Via integrated control unit |

| Dimensions (W x H x D) | 315 mm x 910 mm x 410 mm |

| Weight | 20 kg |

| Power Supply | |

| Voltage | 24 V DC |

| Supply via connection unit | |

| Power Consumption | 36 W |

SICK GM32 Ex Gas Analyser – Sender/Receiver Unit

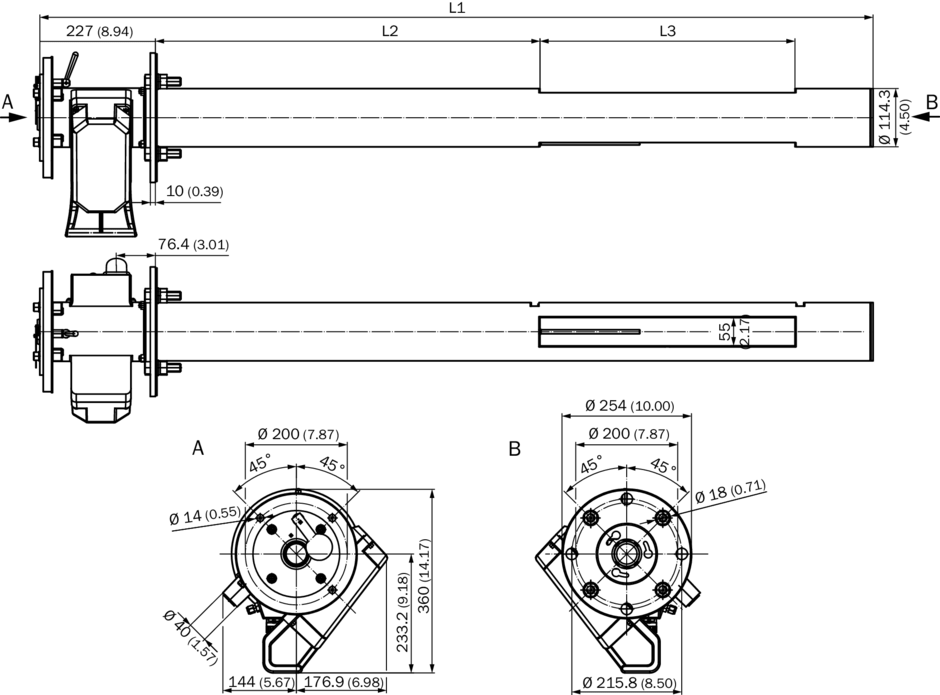

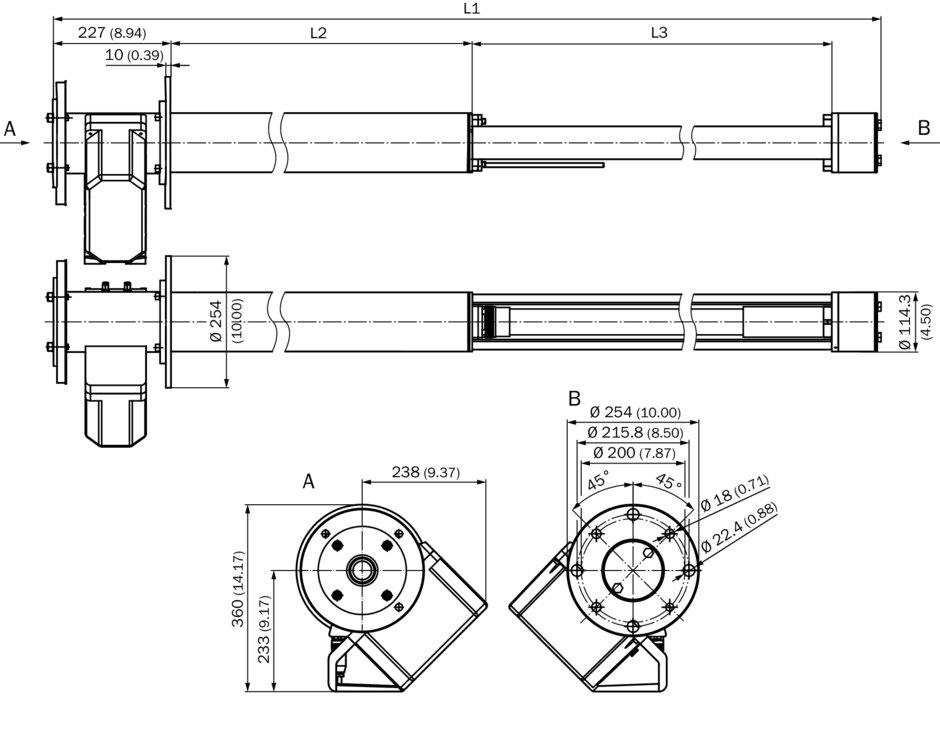

Open Measuring Probe (GMP)

| Description | Measuring probe in open design with integrated purge air control system |

| Measuring Distance | see Data Sheet |

| Accuracy | |

| Pressure Sensor | 1% |

| Temperature Sensor | 1% |

| Process Temperature | ≤ +550 °C |

| Process Pressure | –60 hPa … 30 hPa Depending on purge air supply |

| Dust Load | ≤ 3 g/m³ Based on a 1 m measuring distance, depending on application |

| Electrical Safety | CE |

| Dimensions (W x H x D) | see Data Sheet |

| Weight | |

| Material in Contact with Media | Stainless steel 1.4571, stainless steel 1.4539 |

| Power Supply | |

| Voltage | Supply via sender/receiver unit |

| Auxiliary Gas Connections | |

| Purge Air | Hose nozzle 40 mm |

| Integrated Components | Pressure sensor (Not Ex version) PT1000 temperature sensor (Not Ex version) Flow monitor for purge air monitoring |

SICK GM32 Gas Analyser – Open Measuring Probe (GMP)

Gas-Testable Measuring Probe (GPP)

| Description | Measuring probe with gas permeable filter element for adjustment with test gas |

| Measuring Distance | see Data Sheet |

| Accuracy | |

| Pressure Sensor | 1% |

| Temperature Sensor | 1% |

| Process Temperature |

|

| With Ceramic Filter | ≤ +430 °C Brief (max. 30 min.) up to 550 °C. At temperatures higher than 430 °C, reliable output of measured values can no longer be guaranteed. |

| NH3 Measurement With Ceramic Filter | +300 °C … +430 °C |

| With Teflon Filter | ≤ +200 °C |

| Process Pressure | –120 hPa … 200 hPa |

| Dust Load | ≤ 30 g/m³ |

| Electrical Safety | CE |

| Enclosure Rating | IP65 |

| Dimensions (W x H x D) | see Data Sheet |

| Weight | |

| Material in Contact with Media | Stainless steel 1.4571, stainless steel 1.4539 |

| Power Supply | |

| Voltage | 115 V AC / 230 V AC |

| Frequency | 50 Hz / 60 Hz |

| Power Consumption | ≤ 150 W |

| Auxiliary Gas Connections | |

| Test Gas | Clamp connection 1/4″ |

| Integrated Components | Pressure sensor PT1000 temperature sensor Heating of optical surfaces |

SICK GM32 Gas Analyser – Gas-Testable Measuring Probe (GPP)

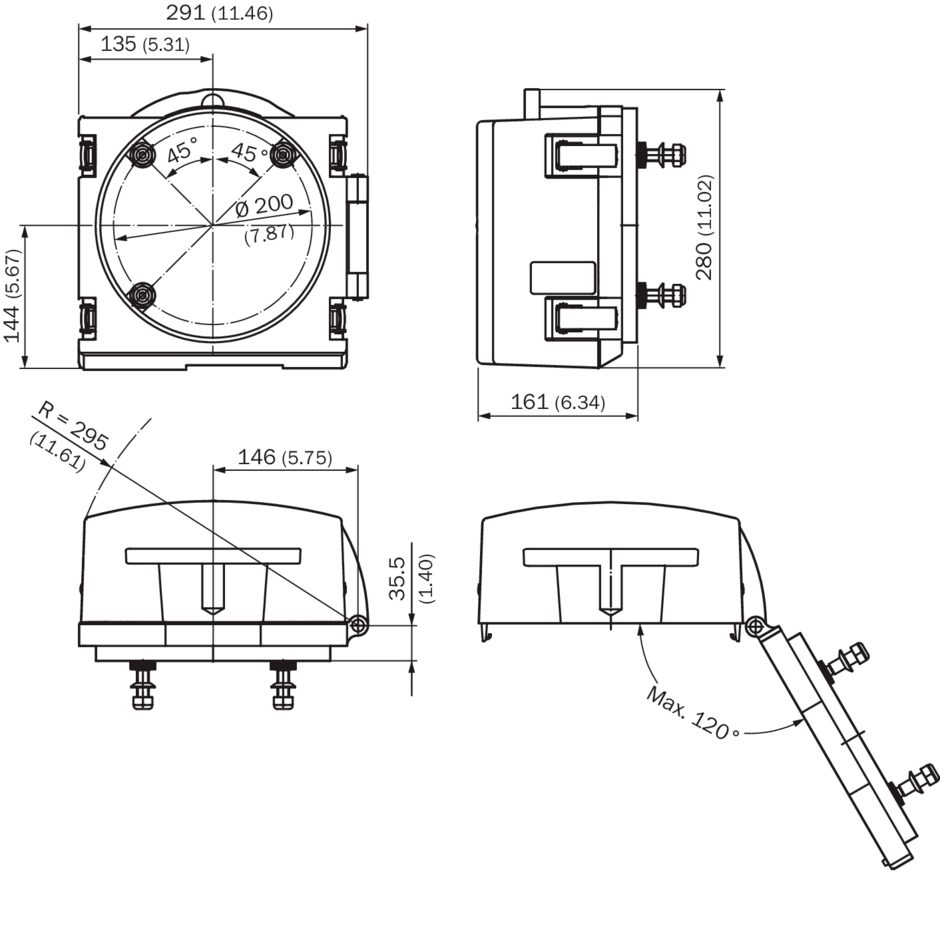

Reflector Unit (Cross-Duct Version)

| Description | Reflector unit with hollow triple reflector |

| Electrical Safety | CE |

| Enclosure Rating | IP65/IP69K |

| Dimensions (W x H x D) | 291 mm x 280 mm x 161 mm |

| Weight | 8.5 kg |

| Process Temperature | ≤ +650 °C |

| Process Pressure | –60 hPa … 30 hPa Depending on purge air supply |

| Dust Load | ≤ 3 g/m³ Based on a 1 m measuring distance, depending on application |

SICK GM32 In-Situ Gas Analysers – Reflector Unit

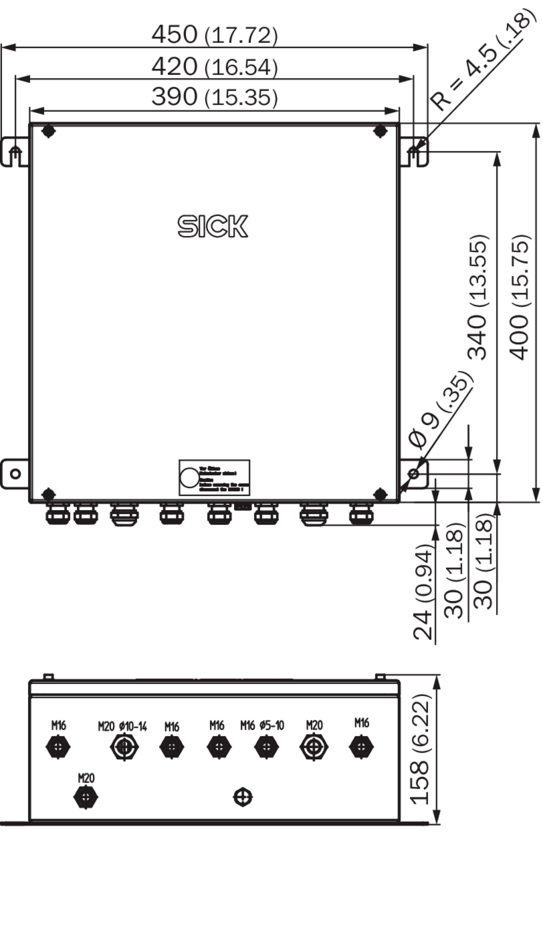

Connection Unit – Standard Version

| Description | Serves for connection of power supply, data and signal cabling provided by the customer |

| Electrical Safety | CE |

| Enclosure Rating | IP65/IP69K |

| Analog Outputs | 2 outputs: 0/4 … 22 mA, 500 Ω Per module, extendable up to eight outputs |

| Analog Inputs | 2 inputs: 0/4 … 22 mA, 100 Ω |

| Digital Outputs | 4 outputs: 48 V AC/DC, 0.5 A, 25 W |

| Digital Inputs | 4 inputs: 3.9 V, 4.5 mA, 0.55 W Per module, extendable up to eight inputs |

| Communication Interface | Modbus CAN bus Ethernet |

| Type of Fieldbus Integration | TCP RTU RS-485 (via optional interface module) |

| Function |

Internal system bus Connection to SOPAS ET software or OPC server |

| Number | 1 |

| Dimensions (W x H x D) | 450 mm x 424 mm x 158 mm |

| Weight | 16kg |

| Power Supply | |

| Voltage | 100 … 250 V AC |

| Frequency | 50 Hz / 60 Hz |

| Power Consumption | ≤ 260 W |

SICK GM32 In-Situ Gas Analysers – Connection Unit (Standard)

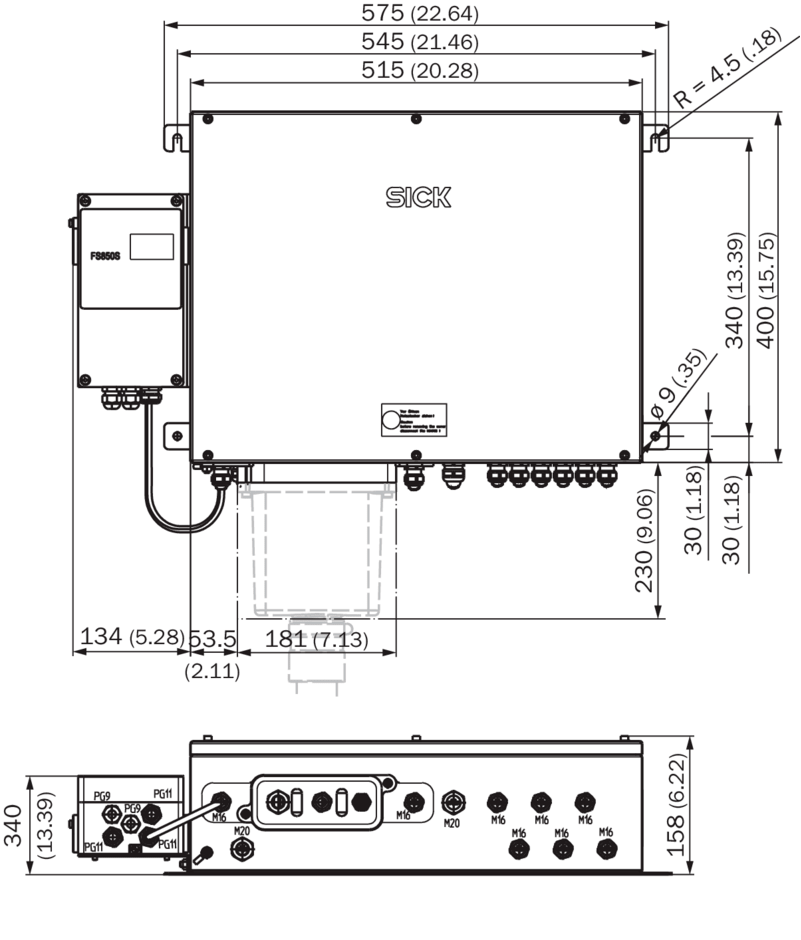

Connection Unit – Ex Version

| Description | Serves for connection of power supply, data and signal cabling provided by the customer |

| Electrical Safety | CE |

| Enclosure Rating | IP65/IP69K |

| Analog Outputs | 2 outputs: 0/4 … 22 mA, 500 Ω Per module, extendable up to eight outputs |

| Analog Inputs | 2 inputs: 0/4 … 22 mA, 100 Ω |

| Digital Outputs | 4 outputs: 48 V AC/DC, 0.5 A, 25 W |

| Digital Inputs | 4 inputs: 3.9 V, 4.5 mA, 0.55 W Per module, extendable up to eight inputs |

| Communication Interface | Modbus CAN bus Ethernet |

| Type of Fieldbus Integration | TCP RTU RS-485 (via optional interface module) |

| Function |

Internal system bus Connection to SOPAS ET software or OPC server |

| Number | 1 |

| Dimensions (W x H x D) | 670 mm x 630 mm x 158 mm |

| Weight | 16kg |

| Power Supply | |

| Voltage | 100 … 230 V AC |

| Frequency | 50 Hz / 60 Hz |

| Power Consumption | ≤ 260 W |

SICK GM32 In-Situ Gas Analyser – Connection Unit (Ex)

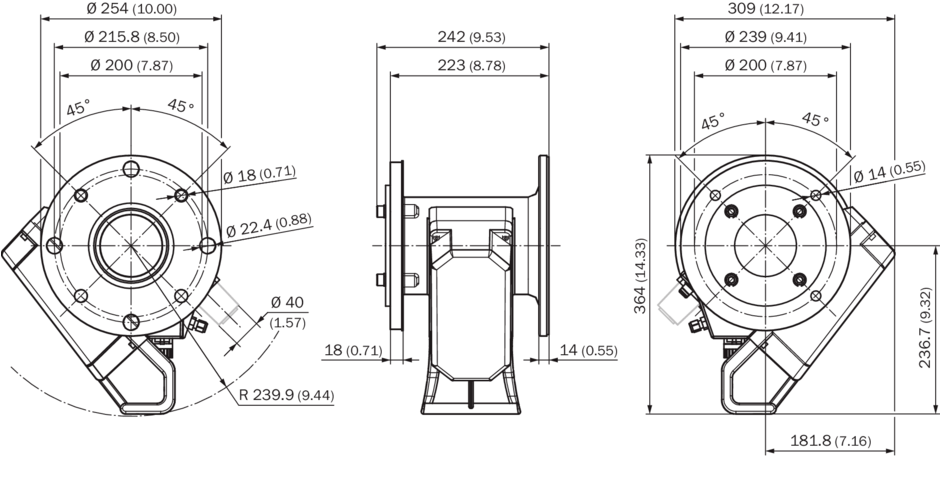

Purge Air Fixture – Sender/Receiver Unit

| Description | Flange fixture for connections for purge air hose, temperature and pressure sensor |

| Electrical Safety | CE |

| Dimensions (W x H x D) | 309 mm x 364 mm x 242 mm |

| Weight | 9.6 kg |

| Auxiliary Gas Connections | |

| Purge Air | Hose nozzle 40 mm |

| Electrical Connections | Purge air unit low-pressure monitor PT1000 temperature sensor Pressure sensor |

| Integrated Components | Flow monitor for purge air monitoring Pressure sensor |

Purge Air Fixture – Reflector Unit

| Description | Flange fixture for connections for purge air hose, temperature and pressure sensor |

| Electrical Safety | CE |

| Dimensions (W x H x D) | 309 mm x 364 mm x 242 mm |

| Weight | 9.6 kg |

| Auxiliary Gas Connections | |

| Purge Air | Hose nozzle 40 mm |

| Electrical Connections | Purge air unit low-pressure monitor |

| Integrated Components | Flow monitor for purge air monitoring |

SICK GM32 IN-Situ Gas Analyser – Purge Air Fixture

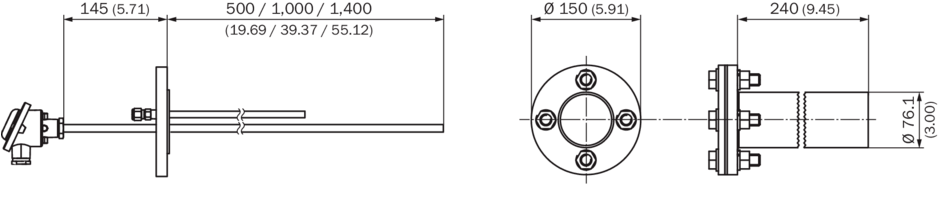

Pressure and Temperature Sensor (Cross-Duct Version)

| Description | Pressure and temperature sensor with DN40 / PN40 mounting flange |

| Accuracy | |

| Pressure Sensor | 1% |

| Temperature Sensor | 1% |

| Process Temperature | ≤ +500 °C |

| Electrical Safety | CE |

| Dimensions (W x H x D) | Dimensions may vary. see Data Sheet |

| Immersion Depth – PT1000 Temperature Sensor | 500mm 1000mm 1400mm |

| Material | Stainless steel 1.4571, steel ST37 |

| Scope of Delivery | Connecting cable for temperature sensor, 5m Connecting hose for pressure sensor, 5 m Flange cover, including seal and screws |

SICK GM32 – Pressure & Temperature Sensor with DN40/PN40 Mounting Flange

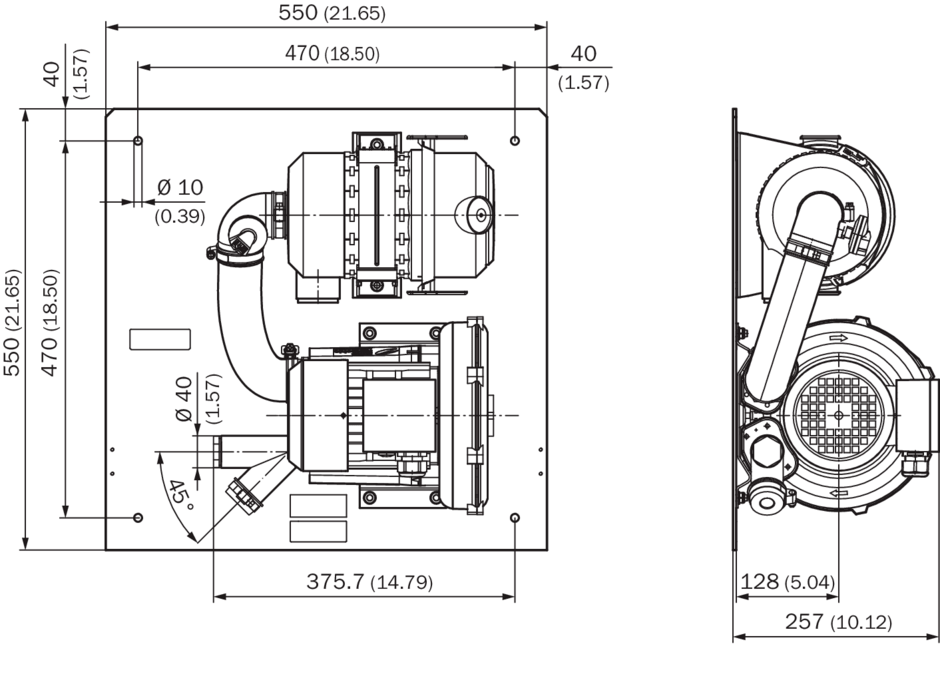

SLV4-2 Purge Air Unit, 2BH1300, 3-ph

| Description | Unit to provide dust-free air for flushing of optical surfaces |

| Gas Flow Rate | 38 m³/h … 63 m³/h At 30 hPa counter pressure, depending on low pressure inside the filter |

| Ambient Temperature | –40 °C … +55 °C |

| Electrical Safety | CE |

| Enclosure Rating | IP54 |

| Dimensions (W x H x D) | 550 mm x 550 mm x 258 mm |

| Weight | 18 kg |

| Power Supply – Three-Phase Current | Δ: 200 … 240 V, 50 Hz, 2,6 A, 400 W Y: 345 … 415 V, 50 Hz, 1,5 A, 400 W Δ: 200 … 275 V, 60 Hz, 2,6 A, 500 W Y: 380 … 480 V, 60 Hz, 1,5 A, 500 W Δ: 270 … 330 V, 50 Hz, 2,0 A, 400 W Y: 465 … 570 V, 50 Hz, 1,16 A, 400 W Δ: 290 … 360 V, 60 Hz, 2,1 A, 500 W Y: 500 … 600 V, 60 Hz, 1,26 A, 500 W Δ: 230 V, 50 Hz, 2,7 A, 370 W Δ: 115 V, 60 Hz, 3,0 A, 450 W Δ: 220 … 270 V, 50 Hz, 2,5 A, 400 W Y: 380 … 465 V, 50 Hz, 1,45 A, 400 W Δ: 240 … 290 V, 60 Hz, 2,6 A, 500 W Y: 415 … 500 V, 60 Hz, 1,55 A, 500 W |

| Auxiliary Gas Connections | |

| Purge Air | 40 mm |

| Test Functions | Pressure switch (switching point –35 hPa) |

| Integrated Components | 2-step air filter, type Europiclon, dust capacity 200 g |

SICK GM32 Gas Analyser – SLV4-2 purge air unit, 2BH1300, 3-ph

SLV6-1 Purge Air Unit, 2SH1300, ATEX 3G

| Description | Unit to provide dust-free air for flushing of optical surfaces; for potentially explosive atmospheres |

| Gas Flow Rate | 38 m³/h … 63 m³/h At 30 hPa counter pressure, depending on low pressure inside the filter |

| Ambient Temperature | –20 °C … +40 °C |

| Hazardous Area Approvals | ATEX Ex II 3G c T3 |

| Electrical Safety | CE |

| Enclosure Rating | IP54 |

| Dimensions (W x H x D) | 550 mm x 681 mm x 287 mm |

| Weight | 28 kg |

| Power Supply – Three-Phase Current | 3-phase: 230 V/400 V, 50 Hz 3-phase: 460 V, 60 Hz |

| Auxiliary Gas Connections | |

| Purge Air | 40 mm |

| Test Functions | Pressure switch (switching point –35 hPa) |

| Integrated Components | 2-step air filter, type Europiclon, dust capacity 200 g |

SICK GM32 Gas Analyser | SLV6-1 Purge Air Unit, 2SH1300, ATEX 3G

Gas, Liquid & Bulk Solids Sensors, Analysers & Detectors from SICK

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES & Hazardous Areas

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters