SICK GMS800 | Extractive Gas Analyser For Process & Emission Monitoring

Extractive Gas Analysers

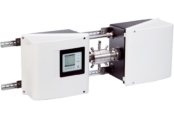

SICK GMS800

Gas analysis for process and emission monitoring

The GMS800 is an extractive gas analyser manufactured by SICK which can measure over 60 different gas compounds and is used for process and emission monitoring.

SICK GMS800 is typified by its modular design: 6 analysing modules, one gas module, I/O modules and an operating unit. Standardised 19″ racks can be used for economic system integration. Wall mounting enclosures with an ATEX approval for use in hazardous areas can also be used for applications within rough industrial environments.

Equipped with modern software, the GMS800 comes with the required interfaces for remote control via networks through to the connection to a process control system.

Typical Applications for SICK GMS800 Gas Analysers

- Emission monitoring according to EN 15267 and process gas measurements, including in potentially explosive atmospheres

- Emission monitoring of very low concentrations

- Measurement of smallest concentrations of NO, NO2, and SO2

- NOx monitoring by direct measurement of NO and NO2

- Measurement of sulphur compounds in process gases

- CO monitoring for explosion protection

- Measurement of smallest concentrations in hydrogen or hydrocarbons

➡ T&D stock Process Instrumentation for industrial processes, explosive atmospheres & hazardous areas.

Pressure Gauges | Solenoid Valves | Flowmeters | Pressure Transmitters & Sensors | Control Valves | Temperature Sensors

SICK GMS800 Gas Analyser

Features

- Approved according to EN 15267 and EN 14181

- Installations in Non-Ex-areas and Ex-areas (Zone 1 and 2 according to ATEX) possible

- Minimum service and maintenance work as well as easy reconditioning of existing installations due to modular design

- Adjustment without test gases via optional adjustment unit

- Minimal influence of ambient temperature through thermostatic controlled modules

- Reliable measuring results by proven measurement technology

- Easy maintenance and repair due to replacement of complete assemblies or modules

- 6 different analyser modules: DEFOR (NDUV, UVRAS), MULTOR (NDIR), OXOR-E (electrochemical O2), OXOR-P (paramagnetic O2), THERMOR (TC), and UNOR (NDIR)

- 4 different types of enclosures

- Gas module with sample gas pump and/or control sensors

- New enclosure type for easy and quick integration in analyser systems

- Remote diagnosis via Ethernet with SOPAS ET software

➡ T&D also distribute the range of SICK In-Situ Gas Analysers

SICK GMS800

Technical SPECIFICATION

Please note: The exact device specifications and performance data of the product may deviate from the information provided here, and depend on the application in which the product is being used and the relevant customer specifications.

GMS800 System

| Measured Values | Ar, CH4, CH3OH, C2H2, C2H2F4, C2H4, C3H6, C3H8, C4H6, Cl2, CO, CO2, COCl2, COS, CS2, H2, H2S, He, NH3, NO, N2O, NO2, O2, SF6, SO2, other components on request |

| Performance Tested Measurands | CH4, CO, CO2, NO, NO2, O2, SO2 |

| Gas Flow Rate | 30 l/h … 60 l/h |

| Sample Gas Temperature | Analyser Inlet: 0 °C … +45 °C |

| Process Pressure | Hosed Gas Lines: –200 hPa … 300 hPa Tubed Gas Lines: –200 hPa … 1,000 hPa |

| Process Gas Humidity | Non-condensing |

| Dust Load | Free of dust and aerosols |

| Ambient Temperature | +5 °C … +45 °C |

| Storage Temperature | –20 °C … +70 °C |

| Ambient Pressure | 700 hPa … 1,200 hPa |

| Geographical Altitude | + 2,500 m (above mean sea level) |

| Ambient Humidity | 20 % … 90 % Relative humidity; non-condensing |

| Electrical Safety | CE |

SICK GMS810

GMS810 Design

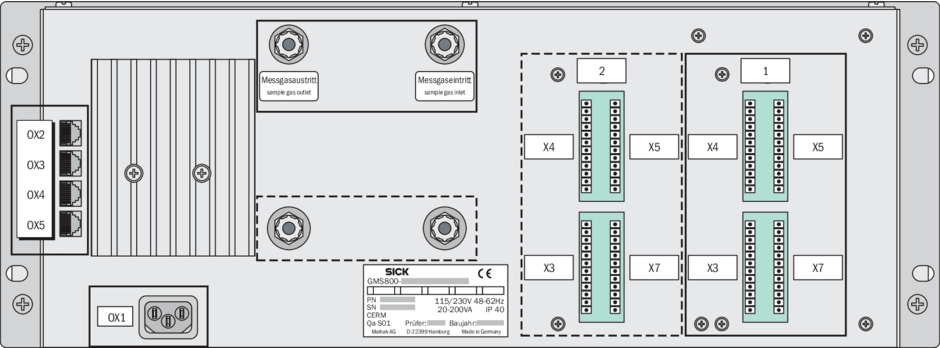

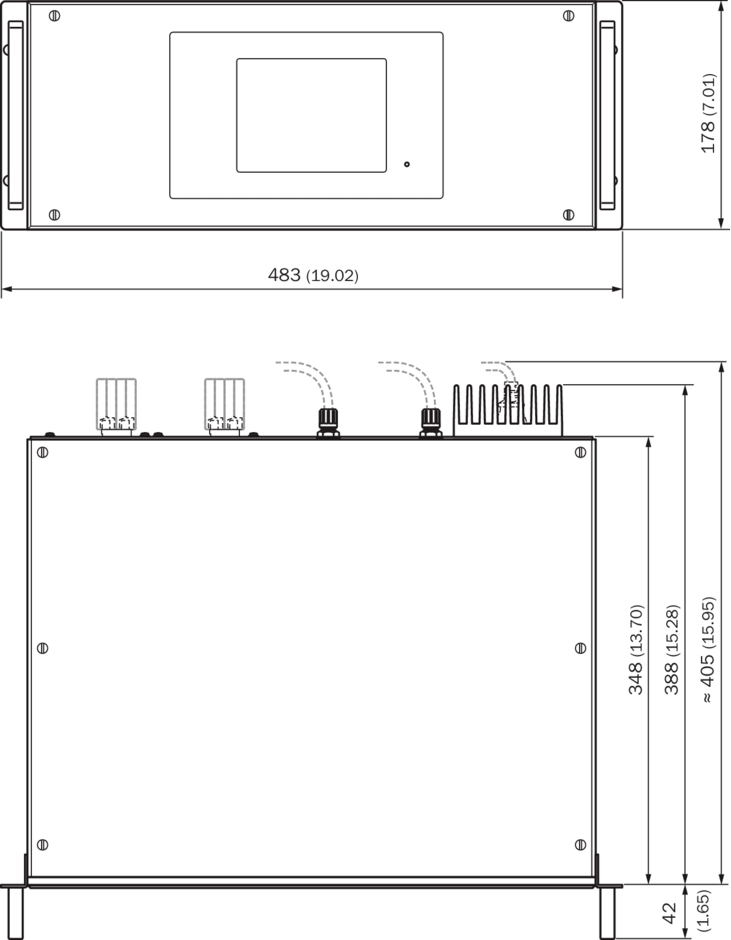

| Description | 19″ rack enclosure with 4 rack units, for integration in cabinets |

| Electrical Safety | CE |

| Enclosure Rating | IP40 |

| Dimensions (W x H x D) | 483 mm x 178 mm x 388 mm |

| Weight | 9 kg … 20 kg Depending on configuration |

| Power Supply | Voltage: 93 … 132 V AC / 186 … 264 V AC / 210 … 370 V AC Frequency: 47 … 63 Hz Power Consumption: ≤ 300W |

| Sample Gas Connections | PVDF bulkhead fitting: for hose 6 x 1 mm |

| Auxiliary gas Connections | For purge gas or flowing reference gas: option |

| Options | Gas connections: Swagelok 6 mm or Swagelok 1/4″ |

SICK GMS810

GMS811 Design

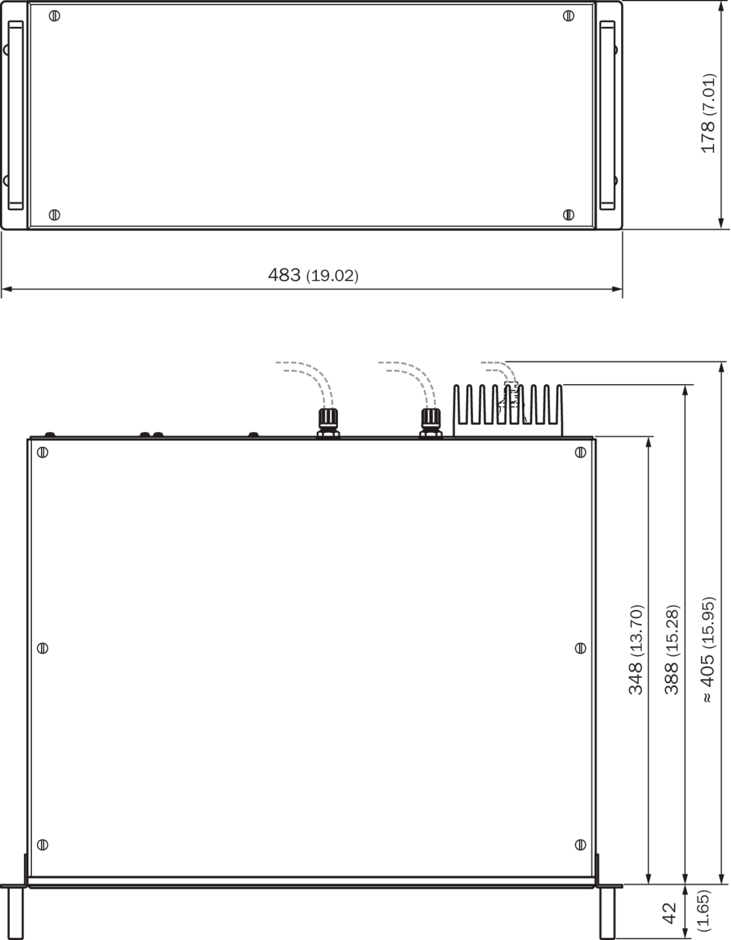

| Description | 19″ rack enclosure with 4 rack units, for usage with separate control unit (BCU), for integration in cabinets |

| Electrical Safety | CE |

| Enclosure Rating | IP40 |

| Dimensions (W x H x D) | 483 mm x 178 mm x 388 mm |

| Weight | 9 kg … 20 kg Depending on configuration |

| Power Supply | Voltage: 93 … 132 V AC / 186 … 264 V AC / 210 … 370 V AC Frequency: 47 … 63 Hz Power Consumption: ≤ 300W |

| Sample Gas Connections | PVDF bulkhead fitting: for hose 6 x 1 mm |

| Auxiliary gas Connections | For purge gas or flowing reference gas: option |

| Options | Gas connections: Swagelok 6 mm or Swagelok 1/4″ |

SICK GMS811

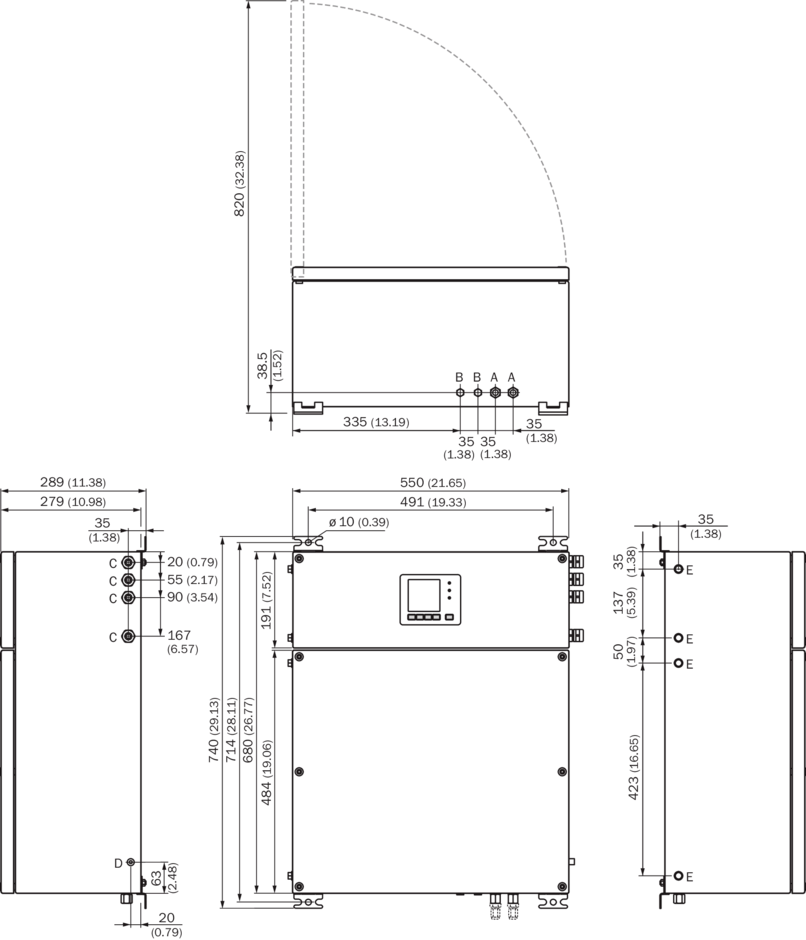

GMS815P Design

| Phase-out | This system component will be phased out soon |

| Description | Wall-mounting enclosure with gas-tight separated analysing and electronic units, purgeable separately |

| Ex Approvals | ATEX: II 3G Ex nR II T6 |

| Electrical Safety | CE |

| Enclosure Rating | IP65/NEMA 4x |

| Dimensions (W x H x D) | 550 mm x 740 mm x 289 mm |

| Weight | 20 kg … 57 kg Depending on configuration |

| Power Supply | Voltage: 93 … 132 V AC / 186 … 264 V (Not with pressurized apparatus: 210 … 370 V) Frequency: 47 … 63 Hz Power Consumption: ≤ 300 W |

| Sample Gas Connections | PVDF bulkhead fitting: for hose 6 x 1 mm |

| Auxiliary Gas Connections | For purge gas or flowing reference gas: option |

| Options | Gas connections: Swagelok 6 mm or Swagelok 1/4″ Integrated flame arrestors for gas inlet and outlet Intrinsically safe outputs for measured values |

SICK GMS815P

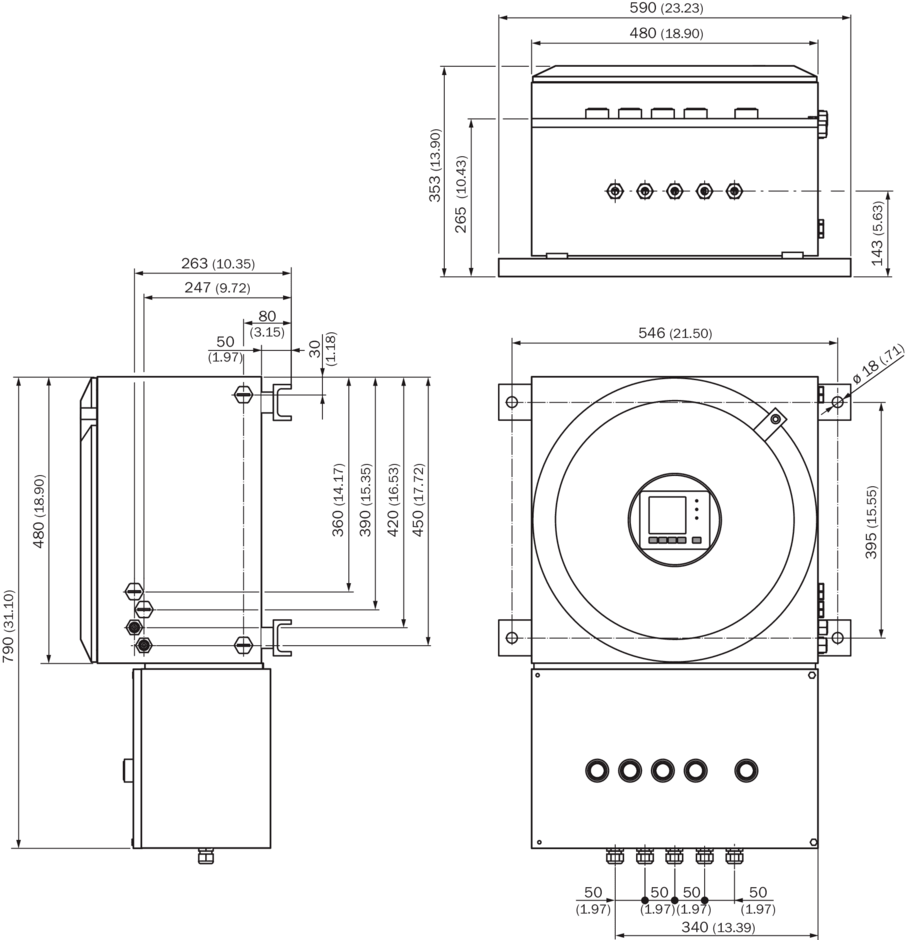

GMS820P Design

| Description | Flame-proof enclosure for use in Ex-zone 1 areas |

| Ex Approvals | IECEx: Ex db eb [ia] IIC T6 ATEX: II 2G Ex db eb [ia] IIC T6 Gb II 2G Ex db eb IIC T6 Gb |

| Electrical Safety | CE |

| Enclosure Rating | IP65 |

| Dimensions (W x H x D) | 790 mm x 590 mm x 353 mm |

| Weight | 140 kg … 150 kg Depending on configuration |

| Power Supply | Voltage: 93 … 132 V AC / 186 … 264 V AC / 210 … 370 V AC Frequency: 47 … 63 Hz Power Consumption: ≤ 300 W |

| Sample Gas Connections | Inside thread G1/4″ |

| Auxiliary Gas Connections | For purge gas or flowing reference gas: option |

| Options | Gas connections: Swagelok 6 mm or Swagelok 1/4″ |

SICK GMS820P

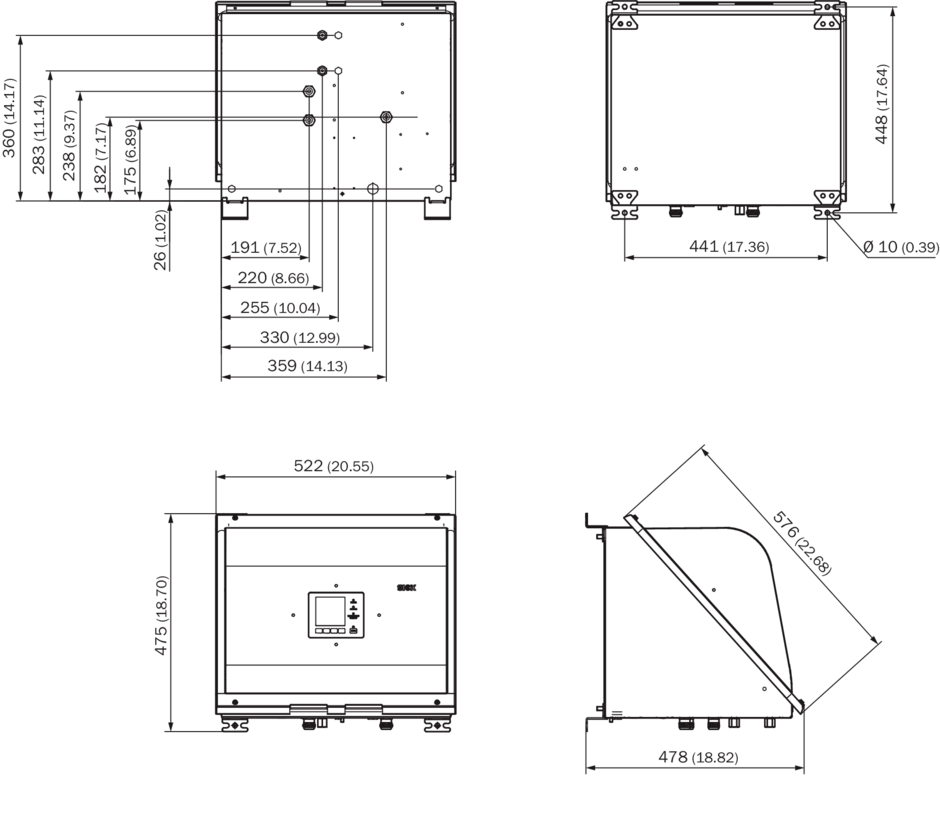

GMS840 Design

| Description | Closed sheet steel housing for wall mounting for use indoors |

| Ambient Temperature | +5 °C … +45 °C |

| Storage Temperature | –10 °C … +70 °C |

| Ambient Humidity | 10 % … 95 % Non-condensing |

| Ex Approvals | IECEx GMS841: Ex nA nC IIC T4 Gc GMS841: Ex nA nC [ia Ga] IIC T4 Gc ATEX GMS841: II 3G Ex nA nC IIC T4 Gc GMS841: II 3G Ex nA nC [ia Ga] IIC T4 Gc NEC/CEC (US/CA) GMS842: Class I, Division 2, Group A, B, C, D T4 GMS842: Class I, Zone 2 GMS842: Ex nA nC IIC T4 Gc GMS842: Ex nA nC [ia Ga] IIC T4 Gc GMS842: AEx nA nC IIC T4 Gc GMS842: AEx nA nC [ia Ga] IIC T4 Gc |

| Electrical Safety | CE |

| Enclosure Rating | IP66/NEMA 4x |

| Dimensions (W x H x D) |

522 mm x 475 mm x 478 mm |

| Weight | ≤ 30 kg depending on configuration |

| Power Supply | Voltage: GMS840: 85 … 264 V AC Frequency: 47 … 63 Hz Current Consumption: ≤ 10 A Power Consumption: ≤ 300 W depending on configuration |

| Sample Gas Connections | Inside thread G1/4″: for screw-in fittings Swagelok 6 mm: stainless steel, for metal tube Swagelok 1/4″: stainless steel, for metal tube PVDF compression fitting: for hose 6 x 1 mm |

SICK GMS840

DEFOR analyser module

| Description | UV gas analyser for simultaneous measurement of up to 3 gas components |

| Measurement Principles | NDUV spectroscopy, UVRA spectroscopy |

| Measuring Ranges | Cl2: 0 … 125 ppm / 0 … 100 Vol.-% COS: 0 … 250 ppm / 0 … 100 Vol.-% CS2: 0 … 50 ppm / 0 … 30 Vol.-% H2S: 0 … 25 ppm / 0 … 100 Vol.-% NH3: 0 … 50 ppm / 0 … 100 Vol.-% NO: 0 … 10 ppm / 0 … 100 Vol.-% NO2: 0 … 125 ppm / 0 … 100 Vol.-% NO2(*): 0 … 50 ppm / 0 … 100 Vol.-% SO2: 0 … 25 ppm / 0 … 100 Vol.-% SO2(*): 0 … 10 ppm / 0 … 100 Vol.-% (*) NO2, SO2: Smallest measuring range with daily adjustment of zero point and operation in an air-conditioned environment with temperature stability of ± 2 °C |

| Certified Measuring Ranges | NO: 0 … 50 mg/m³ / 0 … 1,000 mg/m³ / 0 … 2,000 mg/m³ NO2: 0 … 50 mg/m³ / 0 … 500 mg/m³ SO2: 0 … 75 mg/m³ / 0 … 287 mg/m³ / 0 … 2,000 mg/m³ |

| Response Time (t90) | 4 s Typical at 60 l/h, depending on cell length and gas flow |

| Sensitivity Drift | ≤ 1 %: of measuring range full scale per week |

| Zero Point Drift | ≤ 1 %: of measuring range full scale per week Measuring ranges smaller than 2 x smallest measuring range: ≤ 2 %: of measuring range full scale per week |

| Conformities | Approved for plants requiring approval – 2001/80/EC (13. BImSchV) 2000/76/EC (17. BImSchV) 27. BImSchV TA-Luft (Prevention of Air Pollution) EN 15267 EN 14181 MCERTS |

| Corrective Functions | Manual or automatic adjustment with test gases or adjustment cell |

| Test Functions | Self test & fault diagnosis |

MULTOR analyser module

| Description | Multi-component NDIR analyzer for continuous measurement of up to 3 IR-absorbing gases and H2O for internal interference sensitivity correction |

| Measurement Principles | NDIR spectroscopy |

| Measuring Ranges | CH4: 0 … 400 ppm / 0 … 100 Vol.-% CO: 0 … 160 ppm / 0 … 100 Vol.-% CO2: 0 … 100 ppm / 0 … 100 Vol.-% NO: 0 … 190 ppm / 0 … 100 Vol.-% SO2: 0 … 90 ppm / 0 … 100 Vol.-% |

| Certified Measuring Ranges | CH4: 0 … 286 mg/m³ / 0 … 500 mg/m³ CO: 0 … 200 mg/m³ / 0 … 2,000 mg/m³ CO2: 0 … 25 Vol.-% NO: 0 … 250 mg/m³ / 0 … 2,500 mg/m³ SO2: 0 … 250 mg/m³ / 0 … 2,000 mg/m³ |

| Response Time (t90) | ≤ 25 s Typical at 60 l/h, depending on cuvette length, gas flow and number of measuring components |

| Sensitivity Drift | ≤ 1 %: of measuring range full scale per week |

| Zero Point Drift | ≤ 1 %: of measuring range full scale per week Measuring ranges smaller than 2 x smallest measuring range: ≤ 2 %: of measuring range full scale per week |

| Conformities | Approved for plants requiring approval – 2001/80/EC (13. BImSchV) 2000/76/EC (17. BImSchV) 27. BImSchV TA-Luft (Prevention of Air Pollution) EN 15267 EN 14181 MCERTS |

| Corrective Functions | Manual or automatic adjustment with test gases or adjustment cell |

| Test Functions | Self test & fault diagnosis |

SICK GMS800 is suitable for use in applications such as olefins production

OXOR-E analyser module

| Description | Determination of oxygen content using an electrochemical cell |

| Measurement Principles | Electrochemical cell |

| Measuring Ranges | O2: 0 … 10 Vol.-% / 0 … 25 Vol.-% |

| Certified Measuring Ranges | O2: 0 … 25 Vol.-% |

| Response Time (t90) | 20 s Typical at 60 l/h, depending on gas flow |

| Sensitivity Drift | ≤ 2 %: of measuring range full scale per week |

| Zero Point Drift | ≤ 2 %: of smallest measuring range per month |

| Process Pressure | Analyser Inlet: –200 hPa … 300 hPa Relative |

| Conformities | Approved for plants requiring approval – 2001/80/EC (13. BImSchV) 2000/76/EC (17. BImSchV) 27. BImSchV TA-Luft (Prevention of Air Pollution) EN 15267 EN 14181 MCERTS |

| Corrective Functions | Manual or automatic adjustment with test gases |

| Test Functions | Self test & fault diagnosis |

OXOR-P analyser module

| Description | Accurate oxygen analyser which operates according to the paramagnetic measurement principle |

| Measurement Principles | Paramagnetic dumbbell principle |

| Measuring Ranges | O2: 0 … 3 Vol.-% / 0 … 100 Vol.-% (Optional: smallest measuring range 0 … 1 vol%) |

| Certified Measuring Ranges | O2: 0 … 25 Vol.-% |

| Response Time (t90) | ≤ 4 s At a gas flow of 60 l/h |

| Sensitivity Drift | ≤ 1 %: of measuring range full scale per week |

| Zero Point Drift | ≤ 1 %: of smallest measuring range per week Measuring ranges smaller 5 vol%: ≤ 0.05 Vol.-%: per week |

| Process Pressure | Analyser Inlet: –200 hPa … 300 hPa Relative |

| Conformities | Approved for plants requiring approval – 2001/80/EC (13. BImSchV) 2000/76/EC (17. BImSchV) 27. BImSchV TA-Luft (Prevention of Air Pollution) EN 15267 EN 14181 MCERTS |

| Corrective Functions | Manual or automatic adjustment with test gases |

| Test Functions | Self test & fault diagnosis |

| Remark | Special versions with highly solvent-resistant or highly corrosion-resistant measuring cells available |

SICK GMS800 is suitable for use in applications such as hydrogen monitoring

THERMOR analyser module

| Description | Heat conductivity analyser for the determination of concentrations in binary or quasi-binary gas mixtures |

| Measurement Principles | Thermal conductivity measurement |

| Measuring Ranges | Ar in N2: 0 … 10 Vol.-% / 0 … 100 Vol.-% Ar in O2: 0 … 10 Vol.-% / 0 … 100 Vol.-% CH4 in biogas: 0 … 60 Vol.-% / 0 … 100 Vol.-% CO2 in air: 0 … 10 Vol.-% / 0 … 100 Vol.-% H2 in Ar: 0 … 1 Vol.-% / 0 … 100 Vol.-% H2 in CH4: 0 … 1 Vol.-% / 0 … 100 Vol.-% H2 in CO2: 0 … 1 Vol.-% / 0 … 100 Vol.-% H2 in blast furnace gas: 0 … 1 Vol.-% / 0 … 100 Vol.-% H2 in N2: 0 … 1 Vol.-% / 0 … 100 Vol.-% He in N2: 0 … 2 Vol.-% / 0 … 100 Vol.-% NH3 in CO2: 0 … 15 Vol.-% / 0 … 100 Vol.-% NH3 in air: 0 … 15 Vol.-% / 0 … 100 Vol.-% |

| Response Time (t90) | ≤ 20 s At a gas flow of 60 l/h |

| Sensitivity Drift | ≤ 1 %: of measuring range full scale per week |

| Zero Point Drift | ≤ 1 %: of smallest measuring range per week Measuring ranges smaller than 2 x smallest measuring range: ≤ 2 %: of smallest measuring range per week |

| Corrective Functions | Manual or automated adjustment with test gases |

| Test Functions | Self test and fault diagnosis |

UNOR analyser module

| Description | Highly selective NDIR analyser for continuous measurement of almost any gas component which absorbs in the infra-red spectral range |

| Measurement Principles | NDIR spectroscopy |

| Measuring Ranges | C2H2: 0 … 300 ppm / 0 … 100 Vol.-% C2H2F4: 0 … 100 ppm / 0 … 100 Vol.-% C2H4: 0 … 300 ppm / 0 … 30 Vol.-% N2O: 0 … 25 ppm / 0 … 100 Vol.-% NO: 0 … 75 ppm / 0 … 100 Vol.-% NH3: 0 … 300 ppm / 0 … 100 Vol.-% C3H6: 0 … 300 ppm / 0 … 100 Vol.-% C3H8: 0 … 100 ppm / 0 … 100 Vol.-% C4H6: 0 … 5,000 ppm / 0 … 20 Vol.-% CH4: 0 … 70 ppm / 0 … 100 Vol.-% CH3OH: 0 … 150 ppm / 0 … 10 Vol.-% CO: 0 … 20 ppm / 0 … 100 Vol.-% CO+CO2: 0 … 50 ppm / 0 … 100 Vol.-% CO2: 0 … 10 ppm / 0 … 100 Vol.-% COCl2: 0 … 200 ppm / 0 … 10 Vol.-% SF6: 0 … 50 ppm / 0 … 100 Vol.-% SO2: 0 … 26 ppm / 0 … 100 Vol.-% More than 60 measuring components available |

| Certified Measuring Ranges | CO: 0 … 75 mg/m³ / 0 … 750 mg/m³ / 0 … 3,000 mg/m³ CO2: 0 … 25 Vol.-% N2O: 0 … 50 mg/m³ / 0 … 500 mg/m³ NO: 0 … 100 mg/m³ / 0 … 1,000 mg/m³ / 0 … 2,000 mg/m³ SO2: 0 … 75 mg/m³ / 0 … 287 mg/m³ / 0 … 2,000 mg/m³ NOx: 0 … 100 mg/m³ / 0 … 1,000 mg/m³ / 0 … 2,000 mg/m³ CH4: 0 … 50 mg/m³ / 0 … 500 mg/m³ |

| Response Time (t90) | 3 s Typical at 60 l/h, depending on cell length and gas flow |

| Sensitivity Drift | ≤ 1 %: of measuring range full scale per week |

| Zero Point Drift | ≤ 1 %: of measuring range full scale per week Measuring ranges smaller than 2 x smallest measuring range: ≤ 2 %: of measuring range full scale per week |

| Conformities | Approved for plants requiring approval – 2001/80/EC (13. BImSchV) 2000/76/EC (17. BImSchV) 27. BImSchV TA-Luft (Prevention of Air Pollution) EN 15267 EN 14181 MCERTS |

| Corrective Functions | Manual or automatic adjustment with test gases or adjustment cell |

| Test Functions | Self test & fault diagnosis |

BCU CONTROL UNIT

| Communication Interface | Modbus, Ethernet Type of fieldbus integration: TCP, RTU RS-485 Function: Connection to SOPAS ET software or OPC server |

| Number | 1 |

| Indication | Status LEDs: “Power,” “Failure,” and “Maintenance request” LC display |

| Operation | Via LC display and membrane keyboard |

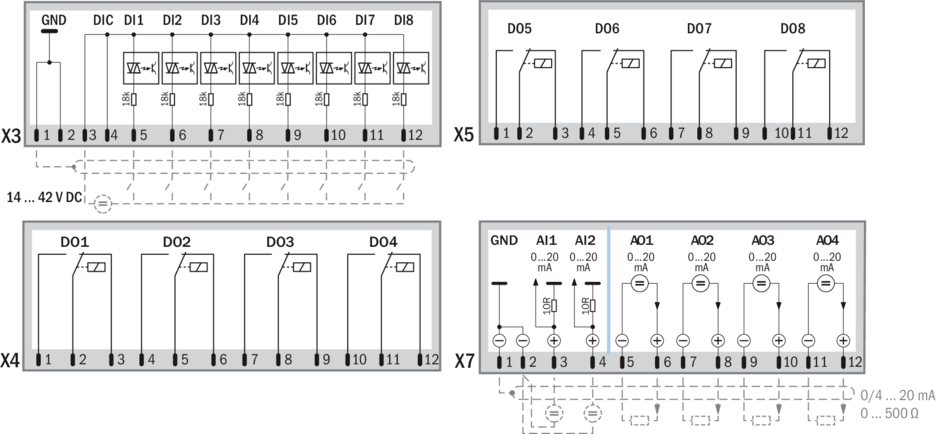

i/o module

| Description | Closed module with top-hat rail adapter or module for integration into enclosures |

| Analog Outputs | 4 outputs: 0/2/4 … 20 mA, 500 Ω Electrically isolated |

| Analog Inputs | 2 inputs: 0/4 … 20 mA Not electrically isolated |

| Digital Outputs | 8 outputs: 34 V AC, 500 mA / 48 V DC, 500 mA |

| Digital Inputs |

8 inputs: 42 V All inlets with common reference potential |

GMS800 I/O Module

gas module

| Sample Gas Connections | PVDF compression fitting: for hose 6 x 1 mm Swagelok 6 mm: stainless steel, for metal tube Swagelok 1/4″: stainless steel, for metal tube |

| Options | Magnetic piston pump (0 … 60 l/h at 100 hPa low pressure) Humidity sensor Pressure sensor (500 … 1500 hPa) Flow sensor (0 … 100 l/h, ±20%) |

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES & Hazardous Areas

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters