SICK MERCEM300Z | Extractive Gas Analyser For Measurement Of Mercury

Extractive Gas Analysers

SICK MERCEM300Z

Innovative measurement of mercury in flue gases

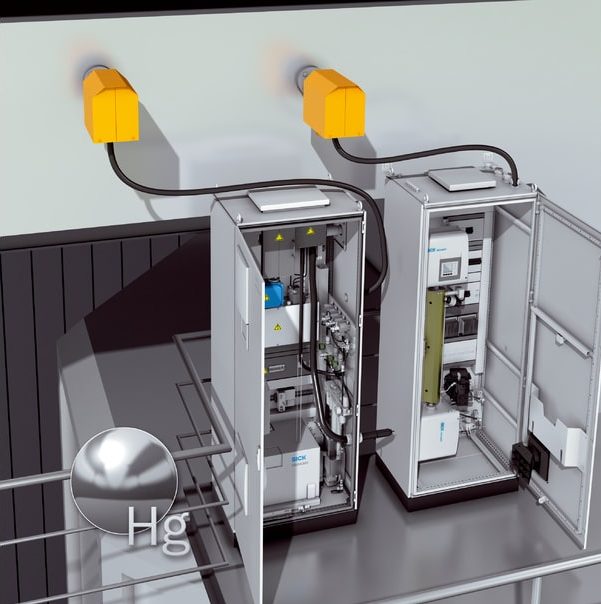

The MERCEM300Z is an extractive gas analyser manufactured by SICK which is used to measure mercury levels in flue gases. This extractive gas analyser monitors Hg emissions in flue gases with a very high reliability, even down to the smallest measuring ranges.

Thanks to a range of housing variants, the MERCEM300Z is suitable for both application in climate-controlled analysis containers and outdoors under exacting ambient conditions. The complete extractive system is designed to meet national and international official requirements.

Typical Applications for SICK MERCEM300Z Gas Analysers

- Emission monitoring in incineration of domestic and hazardous waste

- Emission monitoring in combustion of sewage sludge or hospital waste

- Emission monitoring in cement plants

- Emission monitoring in power stations

- Hg process measurement upstream of electrostatic precipitator or scrubber

SICK Extractive Gas Analysers

SICK MERCEM300Z Gas Analyser

Features

- Reliable results for the actual measured values of elemental and chemically bound Hg in gases

- Extremely low operating cost

- Automated adjustment with test gas for high measurement certainty (optional)

- Minimum maintenance required

- Self-adjusting gas analyser provides high long-term stability without the need for maintenance

- Convenient, quick access for easy service and user-friendly remote diagnostics

- Accurate measurement of “total mercury” directly in a thermal converter (patented)

- Measuring operation without using consumables

- Practically maintenance-free gas sampling using an ejector pump – no moving parts

- Integrated adjustment cell for automated drift checking

- Automated adjustment of the entire measuring system with a built-in test gas generator (optional)

- Completely modular system design

➡ T&D also distribute the range of SICK In-Situ Gas Analysers

SICK MERCEM300Z

Technical SPECIFICATION

Please note: The exact device specifications and performance data of the product may deviate from the information provided here, and depend on the application in which the product is being used and the relevant customer specifications.

| Measured Values | Hg |

| Performance-tested Measurands | Hg |

| Measurement Principles | Zeeman atomic absorption spectroscopy |

| Gas Flow Rate | 150 l/h … 400 l/h |

| Measuring Ranges | Hg: 0 … 1 ppb / 0 … 100 ppb |

| Certified Measuring Ranges | Hg: 0 … 10 µg/m³ / 0 … 45 µg/m³ / 0 … 100 µg/m³ / 0 … 1,000 µg/m³ |

| Sensitivity Drift | < 3 %: within the maintenance interval, relative to measuring range full scale |

| Zero Point Drift | < 3 %: within the maintenance interval, relative to measuring range full scale |

| Detection Limit | < 2 %: relative to measuring range end value |

| Process Temperature | ≤ +1,300 °C |

| Process Pressure | 850 hPa … 1,100 hPa |

| Ambient Temperature | MERCEM300Z: –20 °C … +50 °C MERCEM300Z Indoor: +5 °C … +35 °C |

| Storage Temperature | –20 °C … +40 °C |

| Ambient Pressure | 850 hPa … 1,100 hPa |

| Ambient Humidity | ≤ 80 % Relative humidity; non-condensing |

| Conformities | Approved for plants requiring approval: 2001/80/EC (13. BImSchV) 2000/76/EC (17. BImSchV) 27. BImSchV TA-Luft (Prevention of Air Pollution) EN 15267 EN 14181 MCERTS |

| Electrical Safety | CE |

| Enclosure Rating | MERCEM300Z: IP55 MERCEM300Z Indoor: IP43 |

| Analog Outputs | 2 outputs: 0/4 … 20 mA, + 500 Ω Electrically isolated; additional outputs if using I/O modules (option) |

| Digital Outputs | 4 relay contacts: + 50 V, 4 A Electrically isolated; additional outputs if using I/O modules (option) |

| Digital Inputs | 4 inputs: + 24 V, 0.3 A Electrically isolated; additional inputs if using I/O modules (option) |

| Communication Interface | Modbus Ethernet Type of fieldbus integration: TCP Function: Connection to SOPAS ET software or OPC server |

| Number | 1 |

| Indication | LC display |

| Input | Functional keys |

| Operation | Via LC-display or software SOPAS ET |

| Model | Aluminium cabinet |

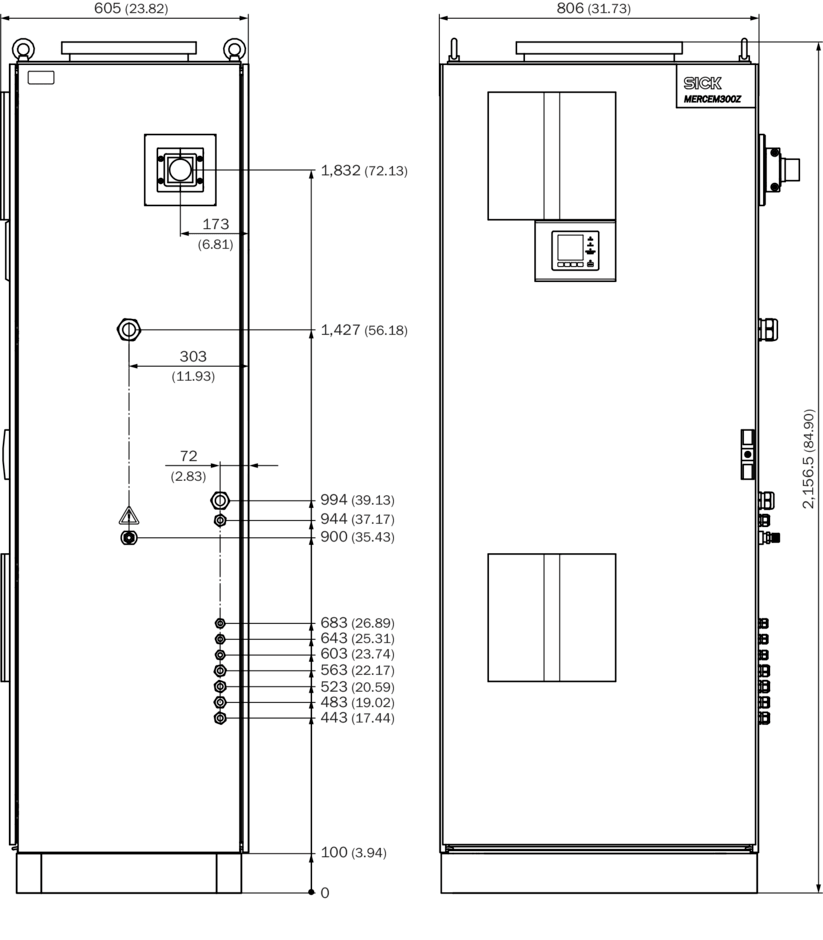

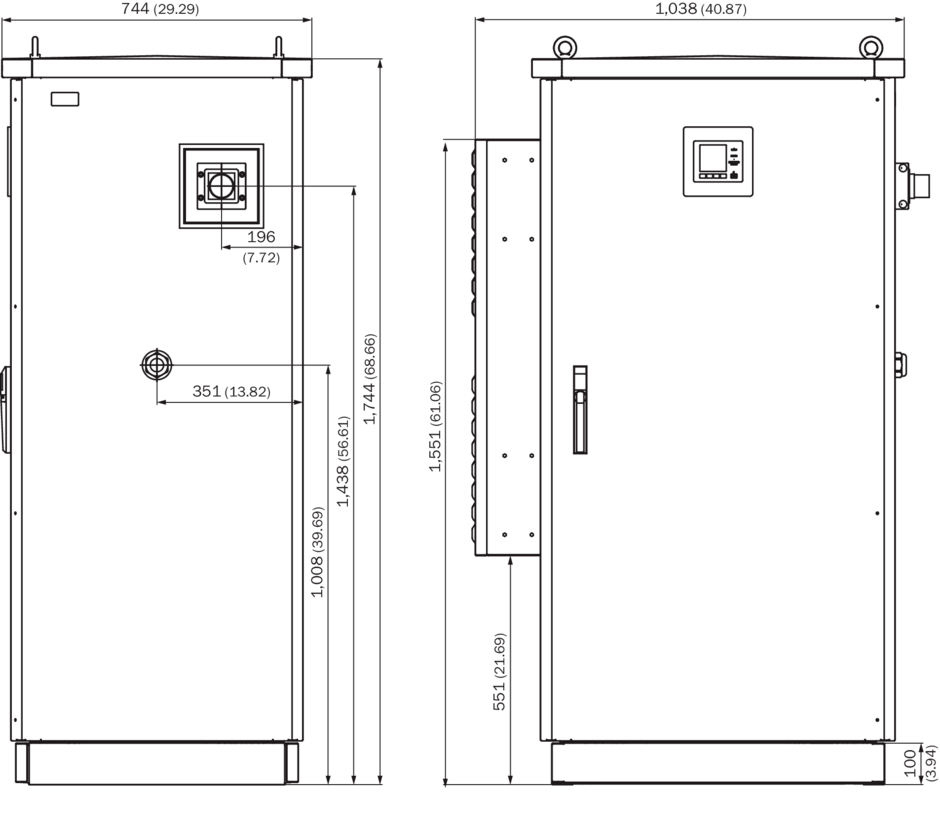

| Dimensions (W x H x D) | MERCE300Z with cooling device: 1,038 mm x 1,744 mm x 744 mm MERCEM300Z Indoor: 806 mm x 2,156.5 mm x 605 mm |

| Weight | ≤ 250 kg |

| Power Supply | Power consumption Without integrated test gas generator: ≤ 2,100 W With integrated test gas generator: ≤ 3,100 W |

| Auxiliaries | Instrument air: ≤ 2,500 l/h 6 … 7 bar; particle size max. 1 µm; oil content max. 0.1 mg/m³; pressure dew point max. –30 °C Test gas: ≤ 500 l/h Max. 0.5 bar; accuracy ±2%; water content 5 … 30 vol.-% |

| Sample Gas Connections | Sample gas inlet: Swagelok 6mm |

| Auxiliary Gas Connections | Test gas: Swagelok 6mm Instrument air: Swagelok 10mm Exhaust gas outlet: Swagelok 10mm |

| Corrective Functions | Internal adjustment cuvette Integrated test gas generator (option) Drift correction (QAL3) and check of the complete system |

| Integrated Components | Integrated conditioning of instrument air (option) Integrated test gas generator (option) |

SICK MERCEM300Z Indoor System | Dimensions in mm (inch)

SICK MERCEM300Z System | Dimensions in mm (inch)

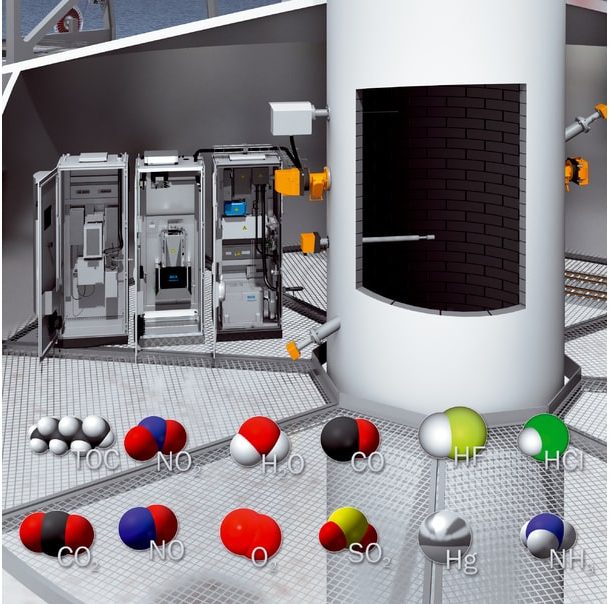

Measurement of flue gas emissions

Environmental regulations stipulate that certain pollutants in the flue gas emitted by cement plants, as well as the reference values, must be continuously monitored.

In many countries, emission measuring technology must be tested for suitability, e.g., in Europe in accordance with EN15267-3, or in the US in compliance with EPA standards.

SICK’s wide product portfolio for emission monitoring provides complete solutions all from one source. These include dust measuring devices from the DUSTHUNTER product family, in-situ gas analysers such as the SICK GM700, and extractive gas analyser systems such as the MCS200HW and MCS100FT.

Gas analysers for special components, such as the MERCEM300Z for mercury (Hg), complete the solution portfolio. The FLOWSIC100CEMS product family provides volume flow measurement. The use of extractive or in-situ technology provides an ideal way to meet local measurement requirements.

Measurement of flue gas emissions

Monitoring mercury separation in flue gas scrubbers

The purpose of the mercury process measurement is to monitor high Hg concentrations (Hg and HgCl2) when incinerating waste of unknown composition.

If the gas purification system is overloaded with very high Hg concentrations (> 3000 µg/m³), counter measures must be promptly taken in order to ensure that emissions thresholds are respected.

Due to the new measuring method with Zeeman measuring technology, this can be done using the MERCEM300Z in a safe and low-maintenance manner, without cross sensitivity, even at higher SO2 concentrations in the raw gas.

Monitoring mercury separation in flue gas scrubbers

ELECTRICAL & PROCESS INSTRUMENTATION EQUIPMENT

FOR EXPLOSIVE ATMOSPHERES & Hazardous Areas

Thorne & Derrick are Specialist Distributors of Hazardous Area & Explosion Proof Equipment with IECEx & ATEX Certifications to the onshore and offshore oil, gas, petrochemicals and process industries.

Key Product Categories: Control Panels | Plugs & Sockets | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace Cables & Systems | Gas Detection & Detectors | Fire Detection & Detectors | Heat Detectors | Electrical Heating & Heaters