Level Measurement In Crude Oil Processing For Storing Raw & Finished Products

Published 29 Jun 2017

Crude Oil Level Measurement

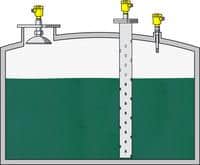

In the petrochemical industry in order for the crude oil process to run continuously and smoothly care has to be taken when storing raw and finished products. Delivery of the crude oil is via pipeline or ship and stored in a large tank until it is ready for final processing.

Accurate level measurement of products of distillation is essential whilst they are being stored in different sized tanks.

In the past it was expensive as calibratable measuring devices were implemented for level measurement. Nowadays cheaper and low maintenance measuring systems are used for small and medium sized tanks. Products are now usually measured by calibratable flow meters while being moved.

Simple Contactless Measurement With VEGAPULS 62

The radar sensor VEGAPULS 62 is suitable for level measurement especially in small and mid-size refinery vessels. Being small and light, the level sensor can be mounted without difficulty in an existing mounting boss, or integrated into a manhole.

With an accuracy of 3 mm, the VEGAPULS 62 sensor is ideal for inventory tank management and can easily be coupled with superordinate systems. Through the use of a temperature adapter, process temperatures up to 200 °C can be realised enabling level measurement of highly viscous distillation products such as lubricating oil or bitumen. VEGAPULS 62 has also proven itself very well as overfill protection in floating roof vessels.

♦ For hazardous areas and explosive atmospheres visit ATEX Level Sensors.

VEGAFLEX 61 – Using Existing Standpipes & New Technology

Until now, mechanical measuring systems such as float gauges or displacers were often implemented. To guarantee precise measuring results, such devices (VEGAFLEX 61) are used mainly in standpipes. Due to the large equalisation holes in the pipes, it is often impossible to replace existing systems with free radiating radar sensors – the holes cause interfering reflections.

This is a situation in which the guided microwave device provides a simple, as well as reliable, solution for level measurement. When the sensor is mounted in the center of the existing standpipe, a coaxial measuring system with optimal signal transmission is created. The result is high accuracy and dependability, without large expenditures for installation and setup.

Reliable Overfill Protection – VEGASWING 63

In principle, a continuous measuring system can be implemented for overfill protection. However, as a completely different measuring principle, the vibrating level switch VEGASWING 63 provides additional safety. Independent of product characteristics, the level sensor reliably detects the threshold level and thus ensures a high degree of plant safety.

The annual instrument check is carried out quickly and reliably with a simple push of a button on the instrument. VEGASWING 63 is ideally suited for leakage monitoring in tank enclosures.

For further information about the complete range of VEGA Sensors visit level measurement.

Further Reading

Radar Level Measurement – How Does It Work?

Guided Wave Radar Level Sensor – How Does it Work?

VEGAFLEX 81 – Guided Wave Radar Level Measurement In An Ammonia Receiving Tank

VEGAPULS 62 Non Contact Radar Level Sensor Used In The Oil And Gas Industry

Process Instrumentation Equipment

for Hazardous Areas & Explosive Atmospheres

Thorne & Derrick International, based in the UK, distribute Explosion Proof & Hazardous Area Process Instrumentation Equipment (ATEX & IECEx Certified): this includes industrial measurement probes, humidity sensors, data loggers, handheld instruments and transmitters for temperature measurement and monitoring of relative humidity. Additionally, hazardous area instrumentation is also available for monitoring carbon dioxide, differential and process pressure, flow, dew point, water activity and analog signals.

- ASCO – Solenoid Valves for Air, Water, Vacuum, Steam, Oil, Acids and Alkali

- Ashcroft – Pressure Gauges

- Deeter Electronics Ltd – Level Sensors & Float Switches

- Fisher – Control Valves (Rotary, Sanitary & Sliding Stem)

- IFM Electronic – Sensors (Temperature, Flow, Pressure & Level Measurement)

- Katronic – Ultrasonic Flowmeters & Flow Measurement

- KROHNE – Hazardous Area Process Instrumentation, Meters & Measurement

- Micronics – Flow Meters (Ultrasonic Clamp-On Fixed & Portable Meters)

- Rotronic – Sensors, Probes, Indicators, Transmitters & Measurement Instruments

- SICK – Temperature, Level, Pressure & Flow Sensors

- Sika – Temperature Calibrators, Flow Meters & Magnetic Flow Sensors (Magmeters)

- VEGA – Level, Point Level & Pressure Measurement Sensors, Instruments & Transmitters

- Hazardous Area Lighting | Junction Boxes & Enclosures | Plugs | Electrical Panels

- Detection Systems for Hazardous Areas | Gas | Heat | Flame | Fire

Invitation – network, engage, promote

Thorne & Derrick are inviting you to join LinkedIn’s fastest growing Discussion Group – Process & Hazardous Area Industries : Heat Tracing, Gas Detection, Fluid Control & Flow Measurement. News, projects, videos, promotions, whitepapers, jobs, webinars, press plus much more.

ABOUT US

Thorne & Derrick International are your single-source supplier of Electrical, Mechanical, Process & Instrumentation Equipment. T&D provide an outstanding service to UK and international customers – we are highly customer responsive and absolutely committed to providing a world-class service.

T&D supply utilities, power, renewable energy, construction, rail, manufacturing, food/beverage, mining, oil, gas and petrochemical industries – distributing 100,000+ products from 100+ manufacturers from multi-million pound stocks. Since 1985 we have established a solid reputation based on service, integrity and trust.

Further Reading

-

VEGA Level Sensor – VEGAPULS 62 Radar Level Sensor

Size: 939.90 KB

VEGA Level Sensor – VEGAPULS 62 Radar Level Sensor

Size: 939.90 KB

-

VEGA Level Sensor – VEGAFLEX 61 Guided Wave Radar Level Sensor – Specification

Size: 138.24 KB

VEGA Level Sensor – VEGAFLEX 61 Guided Wave Radar Level Sensor – Specification

Size: 138.24 KB

-

VEGA Level Switch – VEGASWING 63 Vibrating Level Switch

Size: 868.69 KB

VEGA Level Switch – VEGASWING 63 Vibrating Level Switch

Size: 868.69 KB