Hazardous Area Connectors | ATEX Zone 1 Zone 2 | Amphenol Amphe-EX

Amphenol Amphe-EX Connectors

Hazardous Area Connectors

ATEX Zone 1 & Zone 2

Amphenol Amphe-EX Connectors

Amphe-EX connectors are a range of hazardous area connectors, manufactured by Amphenol, which are designed for use in ATEX and IECEx rated hazardous locations and potentially explosive atmospheres.

Amphenol Amphe-EX are cylindrical, metal finished, threaded coupling, power and signal connectors. With the ever growing need for more power and signal in a smaller interface in ATEX rated areas, these miniature, explosion-proof threaded connectors are specifically designed to allow a signal to pass through ATEX Zone 1 and Zone 2 rated hazardous areas using coax, fibre optic, or standard copper cables – Fibre optic custom cable assemblies available upon request.

Designed for Hazardous Environments

Amphenol Amphe-EX Connectors

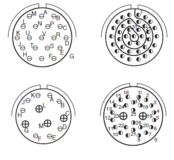

This range of hazardous area connectors are equipped to handle signal, power, RF or fibre optic requirements in the most harsh environments. Amphe-EX connectors offer a complete array of insert patterns, ranging from 2 # 20 contacts, right up to 79 # 22D contacts, and everything in between.

In addition, Amphe-EX is able to provide RJ45 connections and fibre optic termini into an ATEX and IECex approved interconnect solution – Suitable for use in applications in Chemical Manufacturing, Pharmaceutical Manufacturing, Petrochemical Refineries, Land and Offshore Drilling Platforms.

The specific materials and design features of this connector range were originally selected to satisfy the stringent requirements of the Military and Aerospace industries. Amphe-EX connectors are made from machined aluminium components, and plated in a hard anodic coating, which has been designed to withstand the most extreme environments. Double-lead acme threads allow for a self cleaning mating action that does not clog under adverse conditions of ice & snow, mud or sand.

These connectors combine electrical and mechanical capabilities that equal or exceed many of the parameters established by the Military specification MIL-5015.

➡ The Amphe-EX range is complimentary to Amphenol’s industry-proven Star-Line EX rage of hazardous area connectors.

Amphe-ex connectors

specification

Amphe-EX connectors are certified for ATEX Zone 1 and 2 (T6, T5 & T4)

ATEX | IECEx

Gases, Vapours and Mists – Ex de IIC Gb Tamb between -40°c to +55°c

Fibre Optic OP PR – Ex op pr IIC Gb Tamb between -40°c to +55°c *

Fibre Optic OP IS – Ex op is IIC Gb Tamb between -40°c to +55°c *

Combustible Dusts – Ex tb IIIC Db (T80°c & T95°c) IP6X Tamb between -40°c to +55°c

ATEX Certified Zone 1 & 2- Cert. # SIRA 07ATEX1229X

IECEx Certified Zone 1 & 2- Cert # SIR 08.0029X

EAC Ex Zone 1 & 2- Cert #

Cenelec IP68

HIGH TENSILE STRENGTH ALUMINIUM: Bar Stock components precision machined, with points of impact designed for extra strength.

HARD ANODIC PLATING: All machined aluminium parts are finished with a hard, scratch resistant coating per Mil-A-8625, Type III. (300 days salt spray performance)

EASILY ACCESSIBLE WIRE TERMINALS: Conductors are readily terminated to contacts. Cable housings are slipped over conductors after terminating. Cumbersome handling and seating of inserts with conductors attached is eliminated.

LARGE WIRE SPACING: Ample wire space is provided in cable housings and hardware.

CABLE OPTIONS: Cable Gland terminations available to allow variety of cable types including unarmoured, armoured and sheathed cable built to the IEEE-45, UL1309, IEC, BS, DIN and JIC standards. Flexible cables like SOOW-A, W, G-GC and DLO constructions can also be used with the AMPHE-EX series connectors. For Cable Gland information, ask for

Amphenol Cable Glands and Cord Grips catalog # 12- 055.

INSERT VARIATIONS: A broad variety of inserts are offered ranging from 2 # 20 awg, up to 79 # 22D awg contacts. Numerous hybrid inserts available that offer combination copper and Coax/Twinax. In addition, Fibre Optic and RJ45 options available.

ATEX & IECEx Connectors | Power & Signal Connectors | Copper | Fibre Optic | Coaxial | Hazardous Areas

How To Order Amphenol Amphe-EX Connectors

Amphenol Amphe-EX connectors can be ordered by coded part number. The ordering procedure is illustrated by part number EXM-A06-9-35PA01 as shown below:

- EXM – Connector Series by Amphenol

- A – Connector Material

- 06 – Connector Style

- 9 – Shell Size (see table above)

- 35 – Insert Arrangement

- P – Contact Type

- A – Cable Gland Size

- 01 – Alternate Positions

- ( ) – Special Deviations

➡ Caps and cable glands come as standard on all connector assemblies.

Connector Series

EXM – Designates Amphe-EX Series of Amphenol Connectors

Material

A – designates Aluminium Alloy Black Hardcoat

S – designates Stainless Steel 316L

Connector Style

00 – Flangeless Panel Mount Receptacle (Resin)

01 – Fix Inline Receptacle with EX Cable Gland

02 – Panel Mount Receptacle (Resin)

03 – Flangeless Inline Receptacle with EX cable Gland

06 – Plug with EX Cable Gland

Shell Size

9 to 21 size connector shells are available

Insert Arrangement

See insert arrangement chart and inset arrangements illustrations

Copper Contacts included – FO termini are optional and can replace AWG16 contacts

Contact Type

P – Pin contacts (Standard 500 cycles)

S – Socket contacts (Standard 500 cycles)

Cable Back End

IF 01, 03 or 06 – for appropriate cable O.D selection see Cable Gland Selection Chart

IF 00 or 02 – Connector comes with Resin (Epoxy / Potting Compound)

Alternate Positions

Rotation of minor keys. Omit for standard Keyway “N”

See Standard Insert Alternate Positioning

Specials Deviations

Omit for cable gland for Unarmoured cable

BS. . . . EX cable gland for universal armoured cable

BSR . . EX reduced cable gland for universal armoured cable

EXPERTS IN EQUIPMENT FOR EXPLOSIVE ATMOSPHERES

LEADERS IN ATEX INNOVATION TO THE HAZARDOUS AREA INDUSTRIES

Thorne & Derrick are leaders in the development and distribution of Product Innovations that deliver significant improvements to clients plant, people and operational safety in the explosive atmosphere industries.

Your proactive problem solvers experienced in succession planning for the replacement of obsolete, non-conformant and legacy equipment in hazardous areas.

Your first-choice provider of innovative and competitive solutions to ensure ATEX & IECEx Compliance for Hazardous Area Electrical, HVAC & Process Instrumentation Equipment to UK and international projects.

Control Panels | Plugs | Isolators | Enclosures & Junction Boxes | Lighting | Control Stations | Motor Starters | Heat Trace | Gas Detection | Flame Detection | Process Instrumentation | Process Heating | Ventilation Fans | Security Access Control

CEAG | Marechal Electric | Appleton ATX | Plugs Sockets Connectors