Zone 1 Fire Rated Enclosures & Junction Boxes (IEC331 BS6387)

Zone 1 Fire Rated Enclosures & Junction Boxes (IEC331 BS6387)

When installing essential electrical systems such as emergency lighting or fire safety controls, great emphasis is placed upon the fire survivability of the critical components such as fire dampers, actuators and cables that are contained in the area.

Often the specification of the junction boxes and enclosures is neglected with respect to fire resistance and survival. On the basis that any system is only as good as the weakest part, it is important that attention is paid to the junction boxes being utilised for essential systems.

Since there are no recognised tests applicable to junction boxes, it was decided to test the enclosures to the same specification as the cable. At the time of the test (1990) the two main tests for electrical cables were IEC331/1970 and BS6387/1983.

Abtech ensure the fire survival of junction boxes using both the SX (stainless steel enclosure) and BPG (GRP enclosure) ranges.

Fire Rated Electrical Enclosures Test Results

| Enclosure Type | IEC 331 750°C (1382°F) for 3 hours (Flame Only) |

BS6387 ‘C’ 950°C(1742°F) for 3 hours (Flame Only) |

BS6387 ‘Z’ 950°C (1742°F) for 3 hours (External Impact) |

BS6387 ‘W’ 950°C (1742°F) for 3 hours (Water Spray) |

| SX Range | Pass | Pass | Pass | Pass |

| BPG Range | Pass | Pass | Not Tested | Not Tested |

Abtech SX and BPG electrical enclosures and junction boxes when fitted with ceramic terminals are suitable for use in areas designated to require fire resistant cables according to IEC331, BS6387 C (fire alone), BS6387 Z (impact test) and BS6387 W (fire with water test).

Fire Rated Enclosures Standards Explained

IEC 331 Test

The IEC 331 test is used for verifying the resistance to fire of electrical cables where circuit integrity under fire conditions must be maintained.

The standards set under the IEC 331 test state that the cable must be exposed to a flame with a minimum temperature of 750°C for at least 90 minutes.

BS6387 Test

The BS6387 test is designed to determine the performance of a section of cable under specified conditions to ensure the cable maintains its integrity under fire conditions. There are three variations of the BS6387 test: ‘C’, ‘W’ and ‘Z’.

Each category within the test highlights the specific capabilities of the cable under set conditions. These conditions being:

- ‘C’ – Fire alone

- ‘W’ – Fire and water

- ‘Z’ – Fire with mechanical shock

The BS6387 specification recommends each category of the test is carried out at different temperatures for various lengths of time.

The category ‘C’ test with fire alone is conducted at 950ºC for 180 minutes, category ‘W’ tests with fire and water are carried out at 650ºC for 30 minutes and category ‘Z’ tests with fire and mechanical shock are carried out at 950ºC for 15 minutes.

Each video below give a short demonstration of each test and are extracted from BS 6387 test videos via Cavicel S.p.A

| BS6387 ‘C’ – Fire Alone |  |

| BS6387 ‘W’ – Fire And Water |  |

| BS6387 ‘Z’ – Fire With Mechanical Shock |  |

Abtech Fire Rated Enclosures

|

|

Abtech BPG Fire Rated Enclosures Size Guide

| Part Number | Width (mm) | Length (mm) | Depth (mm) | Ex Certified |

| BPG1 | 80 | 75 | 55 | ♦ |

| BPG2 | 110 | 75 | 55 | ♦ |

| BPG3 | 160 | 75 | 55 | ♦ |

| BPG4 | 190 | 75 | 55 | ♦ |

| BPG4.5 | 190 | 75 | 75 | ♦ |

| BPG5 | 230 | 75 | 50 | ♦ |

| BPG6 | 122 | 120 | 90 | ♦ |

| BPG7 | 220 | 120 | 90 | ♦ |

| BPG8 | 160 | 160 | 90 | ♦ |

| BPG9 | 260 | 160 | 90 | ♦ |

| BPG10 | 360 | 160 | 90 | ♦ |

| BPG11 | 560 | 160 | 90 | ♦ |

| BPG12 | 255 | 250 | 120 | ♦ |

| BPG13 | 400 | 250 | 120 | ♦ |

| BPG14 | 600 | 250 | 120 | ♦ |

| BPG15 | 400 | 405 | 120 | ♦ |

Ex certification may be component or apparatus certified – Individual requirements should be specified.

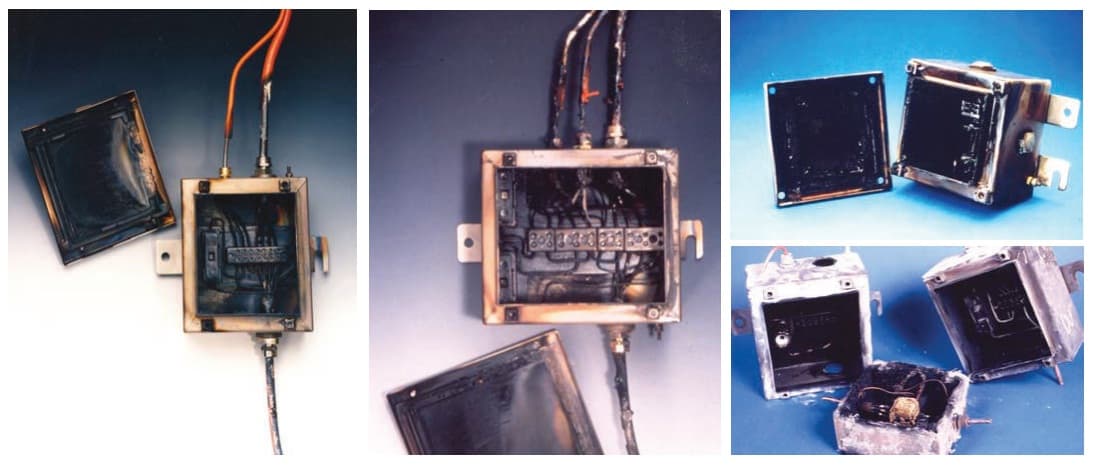

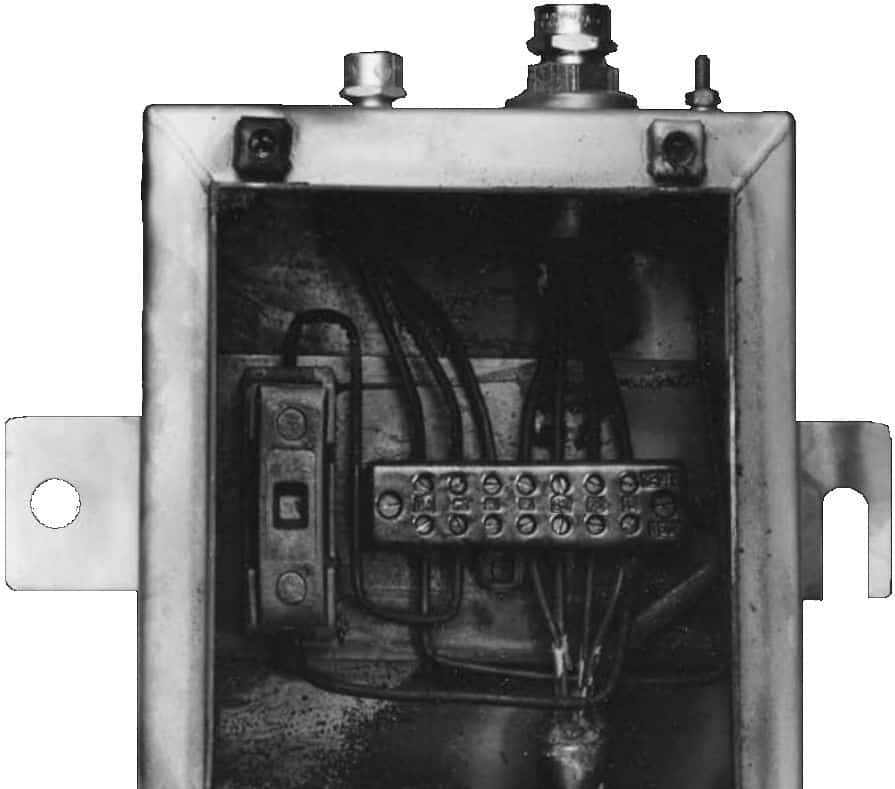

SX Range Enclosure and Cables after IEC331 Fire Testing

SX Range Enclosure after BS6387 Testing

SX and BPG Range Enclosures after BS6387 Testing

Hazardous Area Enclosures: Intrinsically Safe Junction Boxes

T&D, The Explosive Atmosphere Experts, provide a single-source capability for the most extensive range of Electrical, Mechanical, Process & Instrumentation Equipment suitable for hazardous area locations.

- Zone 1 Hazardous Area Lighting

- Zone 2 Hazardous Area Lighting

- Enclosures, Motor Starters & Isolators

| Hazardous Area Coding & Zones | Zone 0 | Zone 20 | Zone 1 | Zone 21 | Zone 2 | Zone 22 |

| Ex e | ♦ | ♦ | ♦ | ♦ | ||

| Ex ai Intrinsic Safety | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ |

| Ex ab | ♦ | ♦ | ♦ | ♦ | ||

| Ex op is | ♦ | ♦ | ♦ | ♦ | ♦ | ♦ |

| Ex nA | ♦ | ♦ | ||||

| Ex nR | ♦ | ♦ |

Hazardous Area Electrical Enclosures & Junction Boxes

With international hazardous area classifications, including ATEX, Abtech BPG GRP junction boxes and enclosures are suitable for onshore and offshore installation in both Zone 1 & Zone 2 hazardous area locations. T&D provide pre-assembled terminal enclosures for use as hazardous area lighting, power, heat tracing and instrument junction boxes with increased safety, intrinsically safe and flameproof explosion protection methods – we can custom supply high voltage enclosures for 3.3kV, 6.6kV, 11kV and 33kV networks.