EXHEAT HFY Flanged Industrial Immersion Heater

EXHEAT Immersion Heaters

Immersion Heater

EXHEAT HFY flanged industrial immersion heater offers a cost effective heating solution for commercial and industrial hot water cylinders, process tank heating and other applications which are non-corrosive to the materials of construction.

The EXHEAT HFY can be supplied with an adjustable thermostat suitable for certain applications.

Typical applications for the EXHEAT HFY flanged industrial immersion heater include hot water storage tanks, heat transfer systems and boiler equipment. Individually replaceable Incoloy 825 elements

The immersion heater is suitable for working pressures of up to 6 barg / 87 psig and has a weatherproof terminal enclosure to IP54

The EXHEAT HFY immersion heater can be easily be installed horizontally unless stated that the heater should be used in vertically orientation.

The HFY immersion heater should be securely fixed in position and all terminal connections checked for tightness before energising.

Features of EXHEAT HFY Immersion Heaters

- Immersion Heaters have individually replaceable Incoloy 825 elements

- Weatherproof terminal enclosure to IP54

- ‘Run Dry’ over temperature protection

- Brass or 316L stainless steel mounting flange

- Heavy duty stud terminals suitable for client cables

- Mounting – designed for horizontal installation only

EXHEAT HFY Flanged Industrial Immersion Heater

EXHEAT HFY Immersion Heater – Applications

Applications for these electric heaters include:

EXHEAT Stockist – Worldwide Delivery, Competitive Quotations

- • Boiler equipment

• Calorifier packages

• Cleaning and rinsing equipment

• Heat transfer system

• Hot water storage tanks

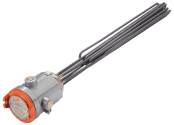

EXHEAT HFY Flanged Industrial Immersion Heater Specifications

| Enclosure | Heavy gauge, corrosion protected, mild steel having a hinged access door and two undrilled removable gland plates for cable entry (finished in grey stove enamel) |

| Flange | Brass or 316L stainless steel having 8 bolt holes, 10mm diameter on 146mm PCD |

| Heating Elements | Nickel chrome resistance wire compacted in high purity magnesium oxide insulating powder and sheathed in corrosion resistant Incoloy; each element is secured to the flange by screwed compression fixings, making them individually replaceable |

| Pressure | The maximum allowable working pressure is 6 barg / 87 psig |

| Thermostat Pockets | Two stainless steel pockets are secured into the flange by screwed compression fittings, one of which is thermally linked to the uppermost element |

| Voltage | Standard units are nominally designed for 415V, and are suitable for operation on 380 to 440V electrical supplies; other voltages and alternative wiring configurations available on request |

| Controls | A capillary type control thermostat and a manual reset cut-out thermostat are fitted as standard |

EXHEAT HFY Flanged Industrial Immersion Heater Product Range

| Model | Load kW 380 V 3PH | Loading kW 415 V 3PH | Loading kW 440 V 3PH | Immersed Length (mm) |

| HFY 1216 | 10.1 | 12 | 13.5 | 405 |

| HFY 1223 | 10.1 | 12 | 13.5 | 584 |

| HFY 1816 | 15.1 | 18 | 20.2 | 405 |

| HFY 1823 | 15.1 | 18 | 20.2 | 584 |

| HFY 2416 | 20.1 | 24 | 27.0 | 405 |

| HFY 2423 | 20.1 | 24 | 27.0 | 584 |

| HFY 3027 | 30.2 | 36 | 40.5 | 685 |

| HFY 4527 | 37.7 | 45 | 50.6 | 685 |

| HFY 5436 | 45.3 | 54 | 60.7 | 915 |

EXHEAT HFY Flanged Industrial Immersion Heater – Dimensions

Air Heaters | Immersion Heaters | Line Heaters | Thermostats | ATEX & IECEX Certified Electrical Heaters

T&D – Experts in Equipment for Explosive Atmospheres

Trust Thorne & Derrick to specify and supply from stock safe and reliable Heat, Light & Power Products for use in hazardous area locations and explosive atmospheres certified to international standards including ATEX and IECEx – this includes Zone 1 / Zone 2 (Flammable Gas) or Zone 21 / Zone 22 (Dusts) and Class I, Division 1 and Division 2 hazardous area requirements.

Since 1985 as Leaders in ATEX Innovation we can facilitate succession planning for the replacement of obsolete, non-conformant and legacy equipment – we are the provider of innovative solutions to ensure ATEX and IECEx Compliance for Electrical, HVAC & Process Instrumentation systems in the explosive atmosphere industries.

Lighting | Sockets | Glands | Control Stations | Isolators | Push Buttons | Hazardous Area Equipment UK & Export Sales

➡ Did you know? T&D have a dedicated Exports and Hazardous Area Sales Team, send an enquiry.

➡ Did you know? T&D are Thermon, The Heat Tracing Specialists, largest UK stockist.

➡ Did you know? T&D are Trained by Crowcon in the specification and sale of Gas Detectors.