Silicone | The Benefits of Silicone for Heating Applications

Published 07 Nov 2019

Silicone Heating Pads | Technical Support | Design | Manufacture | Deliver| Best Prices | Ex Stock | Contact Us

what is silicone?

F. S. Kipping first coined the word silicone in 1901 to describe polydiphenylsiloxane by analogy of its formula, Ph2SiO, with the formula of the ketone benzophenone, Ph2CO.

Silicones are polymers, which are large molecules composed of many repeated sub-units. These polymers are made up of siloxane – a chain of alternating silicon atoms and oxygen atoms frequently combined with carbon and/or hydrogen.

Silicone is an element found in sand, where it is extracted from, and passed through, hydrocarbons. As it is made from sand, silicone is the second most abundant element on Earth. However despite being readily available the cost tends to be high in comparison to other rubbers such as Neoprene, EPDM or natural rubbers. The reason for this is that the process of converting sand into silicone is an expensive procedure. Investing in silicone rubber heaters will give you the satisfaction of a high-performance result in a sensible amount of time.

Why choose silicone?

The choice of silicone heaters is due to a mix of material characteristics and features.

There is a vast choice of rubbers available to engineers and designers on today’s market.

The sheer number of different choices can cause confusion as to which rubber is the most suitable to select for certain applications. Properties such as tear strength, compression set, temperature resistance and elongation may can all affect making a choice.

- Silicone rubber is ideal for outdoor use as it has an excellent resistance to environmental conditions such as weathering from frost, snow and rain as well as stress from UV rays and the ozone.

- Another benefit of silicone (sponge in particular) is low compression set. Meaning that if the silicone is under compression for a length of time, it recovers and maintains its original shape. This is particularly useful when used in confined spaces around pipework, valves and flanges.

- As silicone is an inert polymer and mainly non-reactive, it is popular within the food and beverage industry as it has little to no effect on the products themselves. It is widely used in applications from dairy tubing to brewery hoses on a global scale. It is approved to FDA, BfR and WRAS standards which allow it to be in contact with food or beverages without causing contamination.

the benefits of using silicone for heating

Although it is a popular material for many applications, silicone is not used as widely as some other, cheaper materials so the economies of scale are low. However, for many businesses, the cost of using silicone is easily justified as it is the best-in-class elastomer for extreme temperature environments where other rubbers simply cannot function as well as being non-reactive, stable and resistant to harsh environments.

As it is a flexible material, silicone heaters are able to fit into small, difficult to reach spaces where other mainstream heaters cannot. Silicone heaters are commonly used in residential and commercial applications where space is an issue. What makes silicone so popular for use in so many heating products and applications is the wide variety of temperatures it can withstand whilst maintaining its physical structure and properties. Silicone is an ideal material for use in continuous temperatures as low as -60°C and up to as high as 230°C.

Resistant to Moisture & Chemicals

There are many special grades and forms of silicone rubber, many of which are suitable for use in hazardous areas including: steam resistant, metal detectable, high tear strength, extreme high temperature, extreme low temperature, electrically conductive, chemical/oil/acid/gas resistant, low smoke emitting, and flameproof.

Silicone is the perfect material for use in applications within heating and ventilation systems due to its excellent sealing protection and compression set. Its closed cell structure provides a high level of protection from water, dust and moisture ingress, making this material the ideal choice for preventing heat loss on pipe lines, valves, pumps and flanges as well as frost protection.

Silicone is known to be highly resistant to many dangerous chemicals, as well as the harmful effects that moisture can have on more traditional heating systems. With silicone being impervious to both chemicals and moisture, it is the perfect material to use for an effective transportable heating unit.

Increases Temperatures Quickly

Silicone heaters are constructed with either etched foil or wiring systems which can rapidly heat up to 350° Celsius, giving them enough power to heat up surfaces they come into contact with quickly. The thin construction of silicone heaters allows the material to heat up incredibly quickly. Both etched foils and etched wires create the perfect environment for a fast conduction process, thus improving their efficiency. As silicone is inherently heat-resistant, quickly reaching these high temperatures poses no risk to the heating unit itself.

Lightweight

On average, silicone weighs just over 2.5 grams per cubic centimetre. This means silicone heaters are able to be transported quickly and easily when required. More bulky heating units such as drum heaters, for example, are often large enough to hold over 50 gallons, however moving them from one work space to another can be cumbersome. Silicone heaters are not just lightweight, but they are also well known for their flexibility, making them much easier to store for future use.

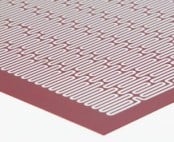

Silicone Heater Mats

Silicone rubber has excellent insulation properties, a low thermal mass, high durability and is resistant to moisture, high temperatures and many chemicals. The use of silicone rubber to manufacture heater mats or heater pads enables the user to achieve more watts per square inch. The mats respond quickly to fluctuations in temperature and can be controlled by thermostats or temperature controllers to keep process temperatures accurate. Silicone heater mats can suit temperatures from -60°C up to +230°C.

Silicone Heater Mats and Pads are flexible heating devices consisting of wires or foil tracks which act as heating elements, between two thin layers of silicone rubber. This construction allows the heat to be evenly distributed across the surface of the mat. Silicone heater mats can be connected to heat control devices such as limit switches, thermocouples or heat sensors to regulate the temperature provided by the heater mat.

There are several types of silicone heater mats available.

They are ideal for use with irregularly shaped structures or where space is limited and fasten to structures using either a special adhesive or hook and eyelet fastenings.

- Wire Wound Silicone Heater Mats have evenly spaced resistance wires laminated between the sheets of silicone. This type of heater mats are robust and ideal for providing heating in applications where the heater is removed and reinstalled regularly. Typical applications for wire wound silicone heater mats include industrial catering such as ovens, battery warming, environmental control and aircraft and laboratory equipment.

- Etched Foil Silicone Heater Mats have chemically etched, foil heating tracks between the sheets of silicone. These heater mats heat up quickly and produce an even and accurate heat. The etched foil tracks have a greater surface area and therefore can be used in applications which require higher power densities. However, the tracks can easily be damaged by bending so this type of silicone heater mats are not suitable for applications in which they would be subjected to flexing and bending. Typical applications for etched foil type silicone heater mats include laboratory equipment, anti-condensation heating, GRP pipe curing systems and satellite dish snow melting.

- Spiral Pipe Heating Silicone Heaters have good resistance to weather & ageing, fungus & bacteria, acetone, alcohol, formic acid, brake fluid, acetic acid, greases, hydrochloric acid 10%, sulphuric Acid 10%, waxes and plasticisers. There are a wide range of uses for spiral heaters where a pipe surface temperature of up to 200°C is required as they are well suited to fit both straight or curved pipework. Spiral type silicone heaters are designed to suit a range of either rigid or flexible, small diameter pipes and are suitable for many applications including gas or fluid delivery, semi conductor processes, frost protection, anti condensation and heat loss maintenance.

- Preformed Silicone Heaters are useful in applications where a heater mat is required to fit small diameter pipework for a more precise fit. Silicone heaters can be formed and vulcanised to fit the full or partial circumference of any pipe diameter. These heaters can be supplied with separate straps for fixing or can be permanently installed using room temperature vulcanising, silicone adhesive or self adhesive systems.

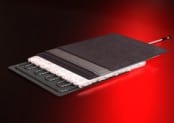

- Kapton Heaters are manufactured from thin, flexible and semi-transparent heating material, Kapton Polymide, which is ideally suited for the production of heater elements. With fast and efficient heat transfer to surfaces, low thermal mass and excellent resistance to chemicals, weather and radiation Kapton allows for high power densities and offers fast response to temperature control. Where low profile, localised heating is required Kapton Heaters are the ideal solution.

- Heating Mats and Jackets are flexible and provide optimum heat transfer with excellent surface heat distribution. They are the ideal solution for simple level surfaces when uniform heating with more than two levels is required – typical applications include OEM and the manufacturing industries where bespoke heating solutions are needed. Heaters can be designed to fit most shapes delivering completely uniform heating profiles across the entire surface over large areas without heat loss, hot spots or colds spots – precise, controlled and targeted heating with no temperature fluctuations.

- Shaped Insulation Foam Silicone Heaters provide high efficiency thermal insulation to help reduce heat loss from pipes, ‘T’ sections, flanges, valves and pumps. Typical applications for these silicone heaters include: frost protection, industrial catering, anti-condensation, GRP pipe curing systems, composite repair of aircraft, environmental control or electronics, heat loss prevention and temperature maintenance.

- Custom Silicone Heaters made from closed cell insulation foam and provide a high efficiency barrier to help reduce heat loss from applications such as liquid or gas pipelines, frost protection, temperature critical pipe line assemblies and to reduce heat loss on valves, pumps and flanges. Silicone rubber products have an excellent resistance to oxidation, ozone, UV light, corona discharge, cosmic radiation and general weathering. The flame retardant pads are available in 3 mm, 5 mm, 8 mm and 12 mm thicknesses.

Trace Heating & Heat Tracing Cable Systems Specialists | Thorne & Derrick

Trace Heating Systems & Heat Trace Cables

The heat trace cable ranges stocked and supplied by Thorne & Derrick International includes electric heating cables for process temperature maintenance, pipe and vessel freeze protection and roof and gutter de-icing applications where snow and ice removal is required – cables and systems are available for commercial, industrial safe area (non-hazardous area) and hazardous area heating applications with ATEX certification.

Electric heat tracing is a cable based system used to maintain, raise temperature and protect process pipework and vessels against freezing temperatures and associated frost damage.

Heat tracing systems utilising self-regulating, constant wattage and mineral insulated (MI) heating cables are available to provide the optimum electrical heating system for your application – we provide a trace heating system design service.

Heat Trace Cables: Ramp Heating | Roof & Gutter Heating | Water Pipework Frost Protection | Hopper Heating | Tank Heating | Hazardous Area Heating | Fire Escapes

EXPERTS IN WINTERISATION SOLUTIONS FOR INDUSTRIAL & HAZARDOUS AREA ENVIRONMENTS

Thorne & Derrick hold the largest UK stocks of frost protection & winterisation equipment to help keep your plant and personnel operational during the winter months.

Thorne & Derrick understand that prolonged periods of low ambient temperatures can bring operations to a standstill costing thousands of pounds in lost downtime.

Experts in heating solutions for use in industrial & explosive atmospheres, Thorne & Derrick have the knowledge & expertise to help clients prevent unnecessary down time this winter.

We can provide overnight delivery of Trace Heating Cables at the most competitive prices to guarantee frost protection of your pipelines and mechanical services.| Ask About Our Heat Trace Design Service.

💡 Contact us today and our skilled and friendly team can provide technical support as well as reliable, fit for purpose and compliant solutions to suit your exact requirements.

Trace Heating | Process Heating | Heating Jackets | Drum & IBC Heaters | Heated Hoses |Silicone Heating Mats

➡See our Winterisation blog TOP PICKS, including our most read articles about Trace Heating and the requirement for electrical heating products and systems to combat and mitigate Winter weather effects.

Competitive Prices | Extensive Stocks | Technical Support | Express Delivery