Guided Wave Radar Level Measurement Using VEGA VEGAFLEX Sensors – How Does it Work?

Published 13 Dec 2016

- By Chris Dodds : estimated reading time 5 minutes

VEGA VEGAFLEX

Level Sensors

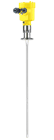

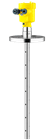

Guided Wave Radar Level Sensor

A guided wave radar level sensor utilising VEGA VEGAFLEX technology uses microwave pulses which are conducted along a cable or rod measuring probe. The measuring probe of the level sensor ensures that the signal reaches the medium undisturbed. The pulse signal is reflected by the mediums surface and is received by the processing electronics. This information is then used and converted into level information.

Level Sensors

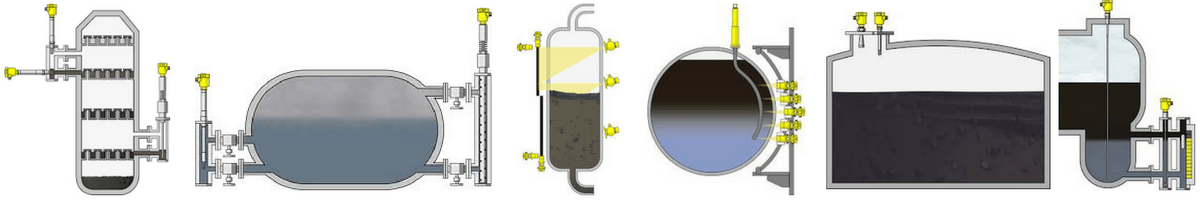

Main Level Sensing Applications

The level of almost any liquid or solid can be measured using VEGA guided wave radar sensors. Guided radar is virtually unaffected by changes to product or process temperature, pressure, density, conductivity, vapours, build up or dust. No moving parts mean the radar level sensors are extremely reliable and eliminates the need for recalibration.

All guided wave radar sensors have built in linearisation software to calculate the level versus shape and provide direct output of volume on:-

- Storage Vessels

- Processing & Manufacturing

- Level Indication – Silos & Hoppers

- Interfaces

VEGA are the worlds’ No.1 process radar manufacturer, with the experience of over 200,000 successful installations. In 1997 VEGA introduced the first two wire, loop powered radar to the market and are the established leaders in this field.

VEga VEGAFLEX Guided Wave Radar Level Sensors

VEGAFLEX series of guided wave radar level sensors are usually mounted from the top. Calibration is easy and uses a small entry to the vessel (from ¾” BSP). VEGAFLEX is part of the plics® family:

- Uses VEGA plics® platform for uniform design, feel and operation

- Make level sensor selection easier, for faster ordering and delivery

- Simple set up, faster commissioning, saves time and money

- Trend and data logging on in head display, VEGA PLICSCOM for real time analysis

- Echo pictures in head offer performance evaluation without laptops

- Cost of purchase and ownership among the lowest in its class

Guided wave radar level measurement

- Measuring range up to 60 metres and can measure very close to the sensor

- High resolution and security of level measurement – unaffected by dust, vapours and build-up

- Built-in echo curve, data logging and trend on the local display

- 4-20 mA two-wire sensors (loop powered)

- Level sensors with digital data transmission (Profibus and FF)

Reliable

- Unaffected by product: changing density, conductivity, moisture, dielectric constant

- No influence from surface reflections, such as agitation, foam or angle of repose from solids

- On solids and powders, filling clouds/dust and obstructions that cause many non-contact systems to misread are no problem either

The following VEGA selection table provides an overview of the VEGAFLEX guided wave radar level sensors available – contact T&D Process & Instrumentation to discuss your level, pressure and temperature measurement requirements.

| Level Measurement Using Guided Wave Radar | VEGA VEGAFLEX Guided Wave Radar Level Sensor | Application | Measuring Distance | Measuring Pressure | Process Temperature | Process Pressure |

|

VEGAFLEX 81 | Liquid level measurement including all liquids – applications with vapour, build-up, foam or condensation | 75 metres | – | -60 to 200°C | -1 to 40 bar |

|

VEGAFLEX 82 | Level measurement of light and heavyweight bulk solids, applications with strong dust generation, condensation or buildup | 75 metres | – | -40 to 200 °C | -1 to 40 bar |

|

VEGAFLEX 83 | Liquid level measurement of aggressive liquids or liquid media with highest hygienic requirements, applications with vapour, build-up, foam generation or condensation | 32 metres | – | -40 to 150°C | -1 to 16 bar |

| VEGAFLEX 86 | Level measurement of virtually all liquids under extreme pressure and temperature conditions, applications with build-up, foam generation or condensation | 75 metres | – | -196 to 450°C | -1 to 400 bar | |

|

VEGAFLEX 61 | Level Measurement | 32 metres | – | -40 to 150°C | -1 to 40 bar |

|

VEGAFLEX 62 | Level Measurement | 60 metres | – | -40 to 150°C | -1 to 40 bar |

|

VEGAFLEX 63 | Level Measurement | 32 metres | – | -40 to 150°C | 0.5 to 16 bar |

|

VEGAFLEX 65 | Level Measurement | 6 metres | – | -40 to 150°C | -1 to 40 bar |

For more information on the VEGAFLEX series of level sensors or any of VEGA’s pressure and level measurement instrumentation please contact a T&D Technical Sales Engineer today.

T&D, Your Explosive Atmosphere Experts – making hazardous areas safe.

Further Reading

Radar Level Measurement Using VEGA VEGAPULS Sensors – How Does It Work?

Guided Wave Radar Level Measurement Using VEGA VEGAFLEX Sensors In The Recycling Industry

Process Instrumentation Equipment

for Hazardous Areas & Explosive Atmospheres

Thorne & Derrick International, based in the UK, distribute Explosion Proof & Hazardous Area Process Instrumentation Equipment (ATEX & IECEx Certified): this includes industrial measurement probes, humidity sensors, data loggers, handheld instruments and transmitters for temperature measurement and monitoring of relative humidity. Additionally, hazardous area instrumentation is also available for monitoring carbon dioxide, differential and process pressure, flow, dew point, water activity and analog signals.

- ASCO – Solenoid Valves for Air, Water, Vacuum, Steam, Oil, Acids and Alkali

- Ashcroft – Pressure Gauges

- Deeter Electronics Ltd – Level Sensors & Float Switches

- Fisher – Control Valves (Rotary, Sanitary & Sliding Stem)

- IFM Electronic – Sensors (Temperature, Flow, Pressure & Level Measurement)

- Katronic – Ultrasonic Flowmeters & Flow Measurement

- KROHNE – Hazardous Area Process Instrumentation, Meters & Measurement

- Micronics – Flow Meters (Ultrasonic Clamp-On Fixed & Portable Meters)

- Rotronic – Sensors, Probes, Indicators, Transmitters & Measurement Instruments

- SICK – Temperature, Level, Pressure & Flow Sensors

- Sika – Temperature Calibrators, Flow Meters & Magnetic Flow Sensors (Magmeters)

- VEGA – Level, Point Level & Pressure Measurement Sensors, Instruments & Transmitters

- Hazardous Area Lighting | Junction Boxes & Enclosures | Plugs | Electrical Panels

- Detection Systems for Hazardous Areas | Gas | Heat | Flame | Fire

Invitation – network, engage, promote

Thorne & Derrick are inviting you to join LinkedIn’s fastest growing Discussion Group – Process & Hazardous Area Industries : Heat Tracing, Gas Detection, Fluid Control & Flow Measurement. News, projects, videos, promotions, whitepapers, jobs, webinars, press plus much more.

ABOUT US

Thorne & Derrick International are your single-source supplier of Electrical, Mechanical, Process & Instrumentation Equipment. T&D provide an outstanding service to UK and international customers – we are highly customer responsive and absolutely committed to providing a world-class service.

T&D supply utilities, power, renewable energy, construction, rail, manufacturing, food/beverage, mining, oil, gas and petrochemical industries – distributing 100,000+ products from 100+ manufacturers from multi-million pound stocks. Since 1985 we have established a solid reputation based on service, integrity and trust.

Further Reading

-

VEGA VEGAFLEX Guided Wave Radar Level Measurement Size: 651.04 KB