How To Correctly Sample Gases Using Pumped Instruments

Published 15 Oct 2020

Gas Detection

Gas Detection in Confined Spaces

Gas Detecting With Pumped Instruments

In many situations, workers must perform pre-entry gas detection checks, to make sure that a confined space is safe before entering. This is often a requirement arising from risk assessment or to allow the issuing of permits to work, or is simply needed because the area is inherently risky.

Whatever the reason, using a pumped device in conjunction with a sampling tube is a great way to perform pre-entry checks to check that a confined space is safe before entry.

An alternative way to detect gases in confined spaces is to lower a portable gas detector into the work area.

gas Detecting in confined spaces

Before You Begin

However, taking measurements in this way brings its own set of challenges and dangers, and when using Crowcon products in pumped or manual sampling modes, all operators should take care to follow these instructions:

- It is strongly recommended that, before proceeding, a function check is performed using the pump and sample tube with the gas/vapour to be detected.

- To reduce the risk of absorption of the gas/vapour in the sample tube, ensure the temperature of the sampling tube is above the flashpoint temperature of the target vapour.

- Ensure the monitor is correctly calibrated for the target gas/vapour.

- Only use the sample tube supplied by Crowcon. It is strongly recommended that ‘reactive gas tubing’ is used for sampling gases/vapours that are likely to be adsorbed (for example, toluene, chlorine, ammonia, hydrogen sulphide, ozone, hydrogen chloride, NOx).

- Keep the sample tube length as short as possible.

- Please allow sufficient time for the gas/vapour to reach the sensor; allow at least 3 seconds per metre plus the normal T90 response time of the sensor (typically 30–40 seconds).

Detecting Reactive Gases

In addition, please note that some of the gases that can be measured by Crowcon gas detection products are classified as ‘reactive’ gases.

A reactive gas will react with, or be absorbed by, the material(s) with which it comes into contact. As a result, the gas concentration reaching the sensor can be reduced, leading to an incorrect reading.

The following list includes some (but not all) reactive gases, which are listed with the appropriate calibration gas. Please contact Crowcon for specific gas concentration information and cross-calibration values).

Target Gas Calibration Gas

Ozone (O3) Ozone (via O3 generator)

Hydrogen Chloride (HCL) Hydrogen Chloride

Hydrogen Fluoride (HF) Hydrogen Chloride or Sulphur Dioxide

Chlorine (Cl2) Chlorine (via Cl2 generator)

Fluorine (F2) Chlorine (via Cl2 generator)

Chlorine Dioxide (ClO2) Chlorine (via Cl2 generator

Phosgene (COCl2) Chlorine (via Cl2 generator)

Sulphur Dioxide (SO2) Sulphur Dioxide

Nitrogen Dioxide (NO2) Nitrogen Dioxide

Nitrogen Monoxide (NO) Nitrogen Monoxide

Ammonia (NH3) Ammonia

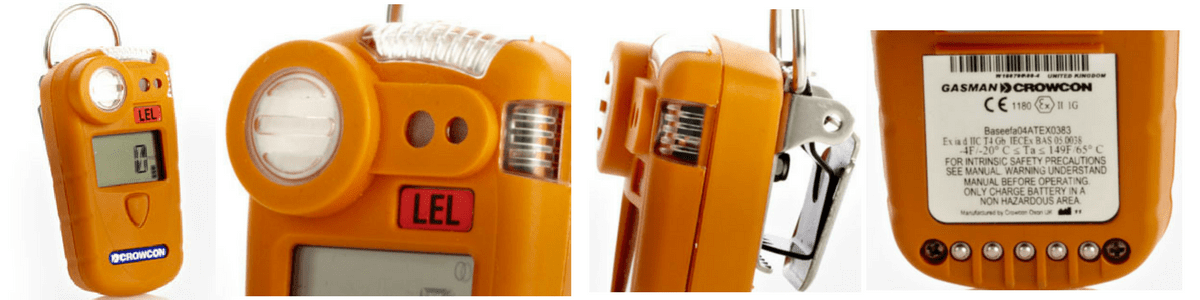

Crowcon Gasman Portable Detector

Gas detecting Equipment & accessories

➡ T&D also stock and distribute a broad range of hazardous area equipment for use in confined spaces.

It is very important that the appropriate accessories and precautions are applied when measuring, calibrating or bump testing sensors that are targeting reactive gasses.

When taking sample measurements: Use Teflon, FEP or PTFE tubing; the tube length must be kept as short as possible (<50 cm), avoid connectors and unions and allow the sample to flow through the regulator/pipe for at least 3 minutes, for initial absorption to occur, before attempting to get a reading.

When calibrating the above points apply in addition to the following:

• The recommended gas flow-rate is 0.5 litres per minute.

• Gas generators are recommended, instead of gas cylinders, for some very unstable gases, especially where very low ppm concentrations are required.

• Use only stainless steel regulators for cylinder gas.

• Ensure the correct calibration adaptor is used, appropriate to the specific product.

Following the above guidance will allow your pumped devices pre-entry checks to deliver accurate measurements – even with reactive gasses – and will keep staff safe and well.

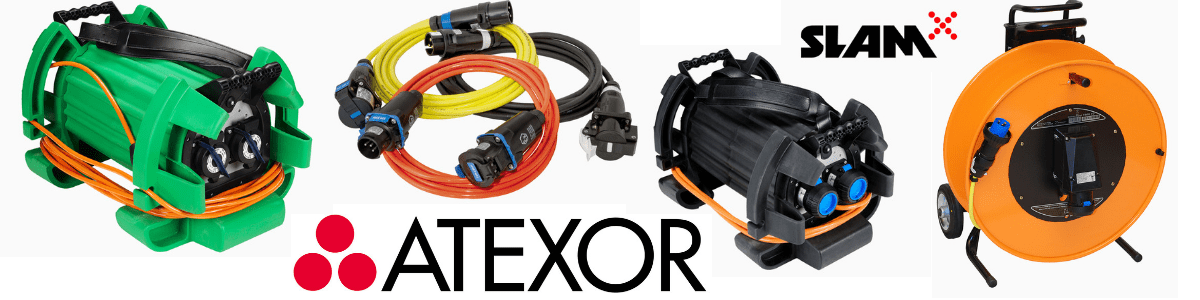

ATEX Certified | Transformers | Cables | Cable Reels | Splitter Boxes

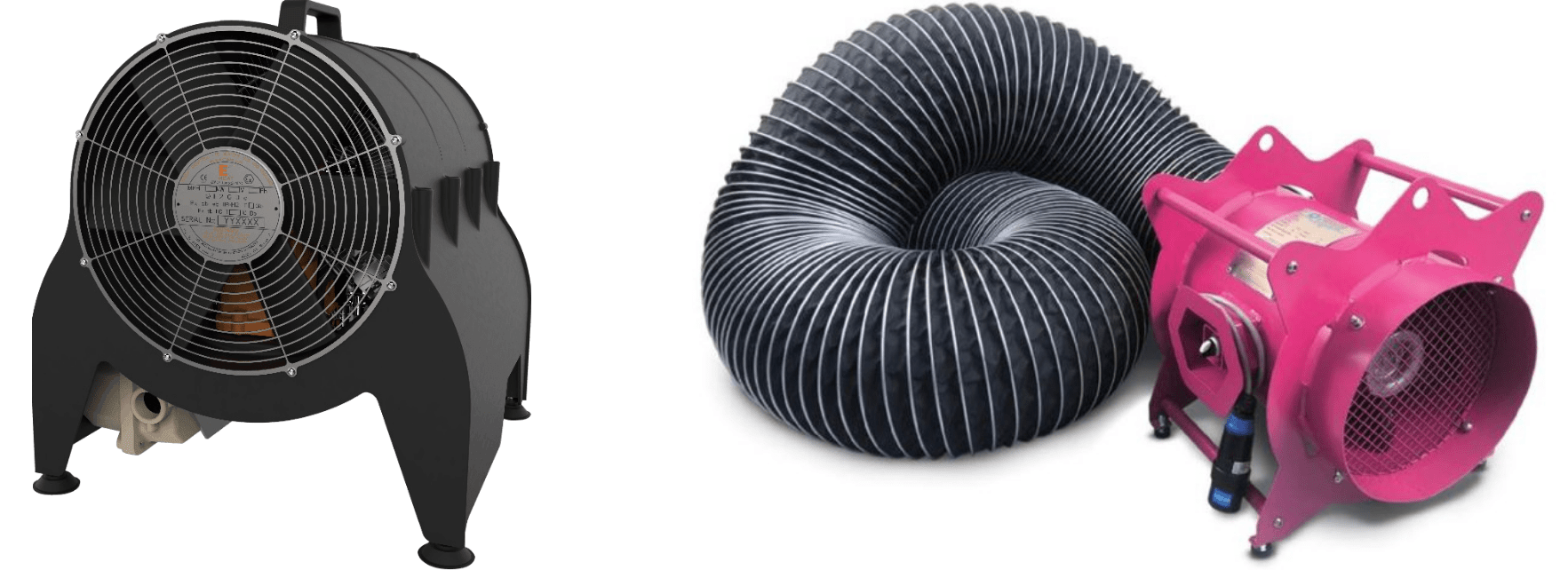

Heating & Ventilation for Confined Spaces

More gas detection Reading

- Hydrogen Sulphide H2S Gas Detection – See How Crowcon Detects H2S Gas Levels

- Hydrogen Sulphide Gas Detection In Refining & Hazardous Area Industries

- Methane Gas Detection – Know The Risks & Detect The Danger

- Ammonia Gas Detection – NH3 Gas Dangers & Detectors

Wolf LinkEx Confined Spaces Lighting Kit ATEX – Hazardous Area Zone 1 & Zone 2

Flame, Heat, Gas Detectors & Detection Systems

![]()

Hazardous area industries including offshore oil/gas platforms and FPSOs, onshore oil refineries, processing plants, pipelines, storage farms and LPG/LNG plants all utilise or produce a wide range of hazardous flammable liquids and gases that can be detected using correctly specified flame and gas detectors.

Detecting toxic and flammable gases requires the detectors to be classified and certified according to the specific IECEx or ATEX standard – we distribute flame and fire detectors manufactured by Spectrex to operate in the harshest environmental conditions including self-contained stand-alone devices designed for direct connection to control and alarm systems or automatic fire extinguishing systems.

Our range of Hazardous Area Fire & Gas Detection System products also includes Explosion Proof Warning Systems & Hazardous Area Lighting – comprehensive range of intrinsically safe, flameproof and explosion proof alarm sounders, sirens, bells and horns, loudspeakers and beacons.

♦ LV Power Products | Junction Boxes & Enclosures ATEX | Plugs ATEX | Control Stations ATEX | Isolators ATEX

Thorne & Derrick | Detecting Flame | Heat | Gas