Chromalox MI Mineral Insulated Trace Heating Cable | ATEX Certified | MI Heating Cables

Frost Protection Trace Heating Cables

Trace Heating

mineral insulated cable

Chromalox MI mineral insulated trace heating cables provide frost protection and temperature maintenance in a variety of demanding applications. With hazardous area certifications from ATEX, IECEx, CSA and FM, the Chromalox MI enables excellent resistance in many corrosive environments. The high nickel alloy sheath, magnesium oxide dielectric insulation and resistance wire construction allow the tracing of equipment up to 1100°F maintenance temperatures and excellent resistance to many corrosive environments. At lower temperatures, watt densities of up to 50 W/Ft can be designed. Please contact factory for cable maintenance temperature above 400°F.

➡ See also: MI Heating Cables

MI Heating Cables – Features

- Constant Wattage Series Resistance Heating Cable Sets

- Corrosion Resistant Alloy 825 or Stainless Steel Sheath

- Factory Assembled Cable Sets—Ready for Installation

- Fully Annealed Sheath allows Field Bending

- Min. Bend Radius 6 x Diameter of Cable

- For Use on Metallic Pipes Only

Trace HEATING CABLEs – SPECIFICATION

- Approximate Cable Size: 3/16″ to 5/16″

- Process Temperature Maintenance: 1112°F (600˚C)

- Maximum Exposure Temperature: 1200°F (648˚C) (Power Off)

- Available Voltages: From 120 to 600V

- MI Heating Cable Circuit Lengths: Up to 500 feet

- Power Outputs : Up to 80 Watts

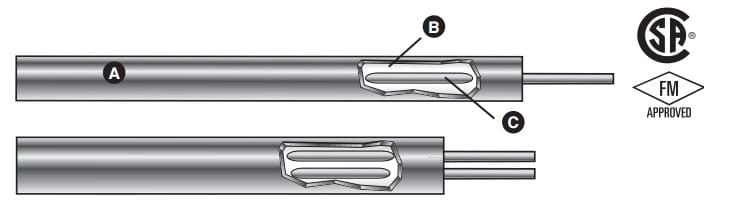

Cable Construction

- A Metal Sheath: High nickel content Alloy 825 is recognised for its use in high temperature applications, and use in many corrosive environments

- B Highly compacted Magnesium Oxide provides insulation of the resistance wire for voltages up to 600V

- C A large number of available resistances enables the design of a large range of lengths and wattages

mi heating cables – available resistance

MI Heating Cables Two Conductor, 3/16” Nominal O.D., Alloy 825, 300 Volts, 0.20 lbs/ft

| Cable Number | Ohms/ft | Maximum Exposure Temperature Rating °F (°C) | Resistance Curve |

| 556K | 0.043 | 600°F (315°C) | 1 |

| 658K | 0.0581 | 1 | |

| 674K | 0.0742 | 1 | |

| 693K | 0.0926 | 1 | |

| 712K | 0.1170 | 1 | |

| 715K | 0.1470 | 1 | |

| 721K | 0.213 | 3 | |

| 732K | 0.319 | 1100°F (593°C) | N/A |

| 742K | 0.416 | ||

| 752K | 0.520 | ||

| 766K | 0.660 | ||

| 774K | 0.740 | ||

| 783K | 0.830 | ||

| 810K | 1.00 | ||

| 813K | 1.30 | ||

| 818K | 1.80 | ||

| 824K | 2.34 | ||

| 830K | 2.96 | ||

| 838K | 3.70 | ||

| 846K | 4.72 | ||

| 860K | 5.60 | ||

| 866K | 6.60 | ||

| 894K | 9.00 | ||

| 919K | 18.00 |

MI Heating Cables Two Conductor, 5/16” Nominal O.D., Alloy 825, 600 Volts, 0.27 lbs/ft

| Cable Number | Ohms/ft | Maximum Exposure Temperature Rating °F (°C) | Resistance Curve |

| 588B | 0.0071 | 600°F (315°C) | 1 |

| 614B | 0.0149 | 1 | |

| 627B | 0.027 | 2 | |

| 640B | 0.040 | 3 | |

| 670B | 0.065 | 1100°F (593°C) | N/A |

| 710B | 0.104 | ||

| 715B | 0.162 | ||

| 720B | 0.205 | ||

| 732B | 0.325 | ||

| 750B | 0.500 | ||

| 774B | 0.735 | ||

| 810B | 1.62 | ||

| 819B | 1.87 | ||

| 830B | 2.97 | ||

| 840B | 4.30 | ||

| 859B | 5.98 |

MI Heating Cables One Conductor, 3/16” Nominal O.D., Alloy 825, 600 Volts, 0.18 lbs/ft

| Cable Number | Ohms/ft | Maximum Exposure Temperature Rating °F (°C) | Resistance Curve |

| 145K | 0.0046 | 600°F (315°C) | 1 |

| 189K | 0.0090 | 2 | |

| 216K | 0.0165 | 3 | |

| 239K | 0.039 | 1100°F (593°C) | N/A |

| 250K | 0.050 | ||

| 279K | 0.079 | ||

| 310K | 0.095 | ||

| 316K | 0.157 | ||

| 326K | 0.260 | ||

| 333K | 0.330 | ||

| 346K | 0.457 | ||

| 372K | 0.730 | ||

| 412K | 1.17 | ||

| 415K | 1.48 | ||

| 423K | 2.36 | ||

| 430K | 2.80 | ||

| 447K | 4.50 |

MI Heating Cables Two Conductor, Stainless Steel, 300 Volts

| Cable Number | Ohms/ft | Maximum Exposure Temperature Rating °F (°C) | Resistance Curve |

| 110S | 11.0000 | 1100°F (593°C) | N/A |

| 900S | 9.0000 | ||

| 750S | 7.5000 | ||

| 600S | 6.0000 | ||

| 400S | 4.0000 | ||

| 275S | 275.00 | ||

| 200S | 2.0000 | ||

| 170S | 1.7000 | ||

| 114S | 1.1400 | ||

| 700S | 0.7000 | ||

| 472S | 0.4720 | ||

| 374S | 0.3740 | ||

| 293S | 0.2930 | ||

| 201S | 0.2000 | ||

| 150S | 0.1500 | ||

| 100S | 0.1000 | ||

| 734S | 0.0734 | ||

| 583S | 0.0583 | ||

| 458S | 0.0458 | ||

| 324S | 0.0324 |

MI Heating Cables Two Conductor, Stainless Steel, 600 Volts

| Cable Number | Ohms/ft | Maximum Exposure Temperature Rating °F (°C) | Resistance Curve |

| 6110S | 11.00000 | 1100°F (593°C) | N/A |

| 6900S | 9.00000 | ||

| 6600S | 6.00000 | ||

| 6414S | 4.14000 | ||

| 6200S | 2.00000 | ||

| 6115S | 1.15000 | ||

| 6700S | 0.70000 | ||

| 6505S | 0.50500 | ||

| 6286S | 0.28600 | ||

| 6201S | 0.20000 | ||

| 6150S | 0.15000 | ||

| 6100S | 0.10000 | ||

| 6775S | 0.07750 | ||

| 6561S | 0.05610 | ||

| 6402S | 0.04020 | ||

| 6281S | 0.02810 | ||

| 6202S | 0.02000 | ||

| 6130S | 0.01300 | ||

| 6818S | 0.00818 | ||

| 6516S | 0.00516 | ||

| 6324S | 0.00324 | ||

| 6204S | 0.00204 | ||

| 6128S | 0.00128 |

Chromalox MI HEATing CABLEs – HAZARDOUS AREA CERTIFICATIONS

FM

- Class I, Division 2, Groups A, B, C, D

- Class I, Zone 2, Group IIC

CSA

- Class I, Division 2, Groups A, B, C, D

- Class II, Division 2, Groups F, G

- Class III, Division

- Class I, Zone 1 and Zone 2, Group IIC

ATEX

- II 2 G Ex e II T1 to T6 Gb

IECEx

- Ex IIC T1 to T6 Gb

Available Designs

Chromalox MI Heating Cables

Hazardous Area Heating Cables

➡ Chris Myers, Product Manager at Chromalox, explains about their heat trace cables and product offering including self regulating trace heating cable.

Industrial Electrical Heating Specialists

We can specify and supply from stock an extensive range of Electrical Heating Equipment for industrial and process heating applications -this includes temperature maintenance and frost protection (Winterisation) products for pipework, valves, IBC’s, drums, hoses, tanks and vessels. We produce custom silicone heaters for rapid and high temperature heat-up of complex shapes and surfaces – from concept, design to the delivery of standard or bespoke heaters on the shortest lead times. From the largest UK heat tracing cable stocks we deliver Electric Trace Heating Systems for pipework frost protection, ramp heating, roof/gutter snow melting and de-icing – enquire about our in-house design service.